Up to eight astronauts will be able to make their own water and oxygen on the moon with a device powered by a thermal solar reactor.

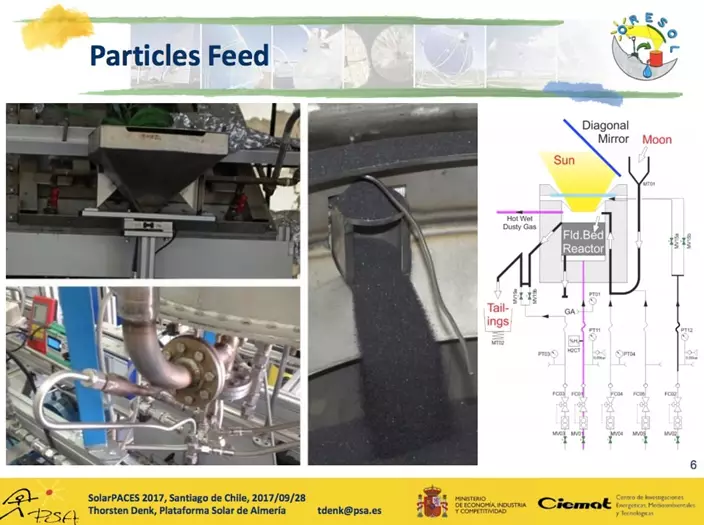

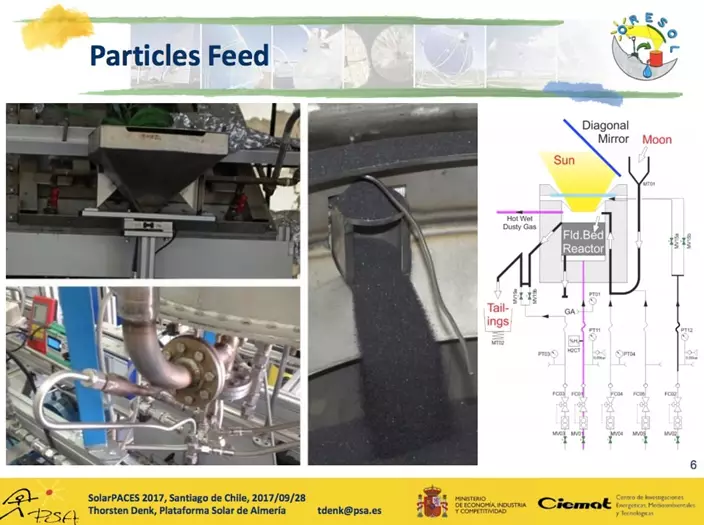

"From the beginning people were thinking this probably has to be done with a solar furnace, because on the moon there is not very much to heat a system that you can use; photovoltaics with electricity or a nuclear reactor or concentrated solar radiation," Thorsten Denk, who has experience in concentrating solar and in particles engineering, was quoted as saying in a news release.

The work was detailed in Denk's paper which was presented this week at the 23rd Annual SolarPACES Conference in Chile.

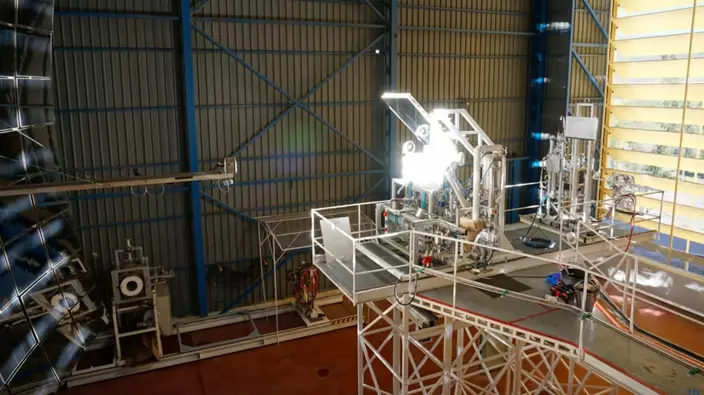

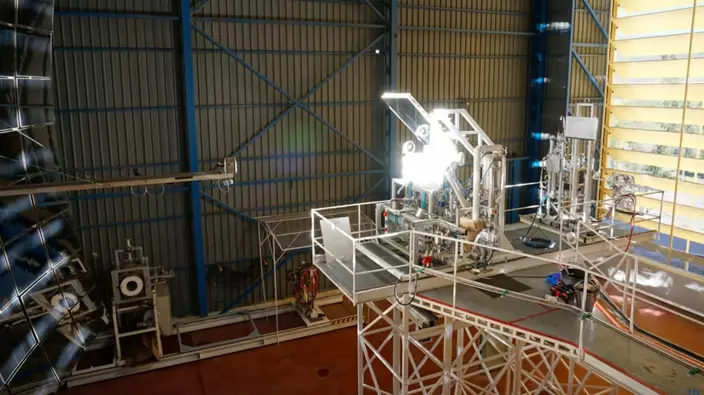

The idea is not new. "After the Apollo missions, scientists had a lot of ideas of how to make oxygen on the moon, because every material that you bring from Earth costs money. For every kilogram of payload you need hundreds of kilograms of fuel," said Denk, who worked on the device for 10 years at the Plataforma Solar de Almeria (CIEMAT).

CIEMAT via SolarPACES

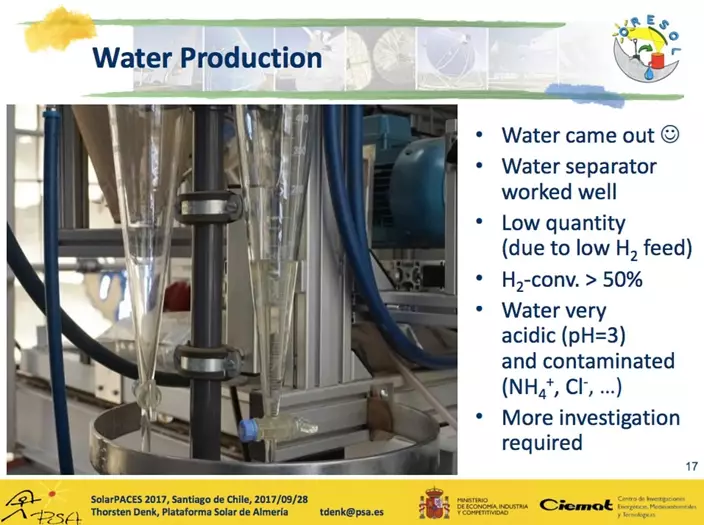

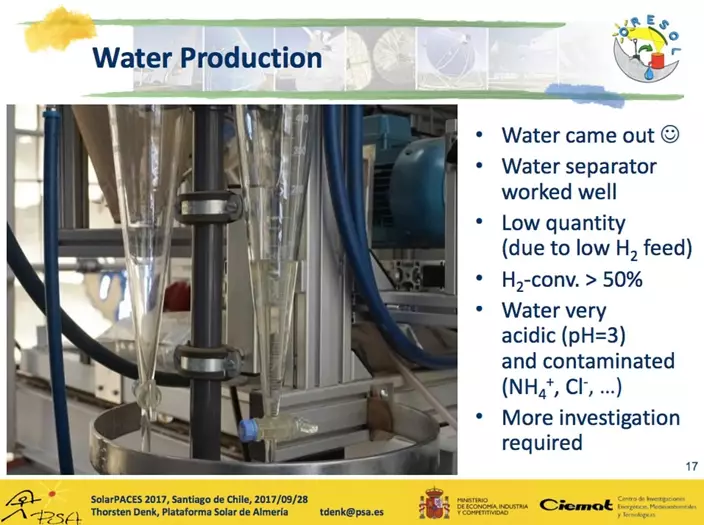

The system could chemically split water from lunar soil and electrolysis could then split the water into oxygen and hydrogen. Unlike soil on Earth, lunar soil does not experience weathering, as the moon does not have an atmosphere.

The machine "is the real size you would build on the moon to make oxygen for a crew of six or eight, so there's no upscaling needed later," said Denk.

The system can extract water from lunar soil, and would only require hydrogen brought from Earth for its initial use, after the first few hours, hydrogen would be recycled from then on.

"Even if you bring hydrogen from Earth and get oxygen from the moon for making rocket fuel, you save nearly 90 percent of the weight. Hydrogen is the lightest element. Oxygen is much heavier," explained Denk.

CIEMAT via SolarPACES

According to the creator, the machine can process 25 kilograms of particle load in less than an hour and currently weighs 400 kilograms, but could be reduced with further refinement. In just one hour, it can make 700 kilograms of water and in four hours, it could produce 2.5 kilograms of oxygen, all using under 10 kilowatt hours of electricity.

The machine has now completed a six-month test run this year. With the successful test of this solar reactor design, Denk has achieved the first step, creating H2O on the moon using solar thermal energy. For the second step, solar electrolysis would break the H2O into hydrogen and oxygen.

ORONO, Maine (AP) — The world’s largest 3D printer has created a house that can cut construction time and labor. An even larger printer unveiled on Tuesday may one day create entire neighborhoods.

The machine revealed Tuesday at the University of Maine is four times larger than the first one — commissioned less than five years ago — and capable of printing ever mightier objects. That includes scaling up its 3D-printed home technology using bio-based materials to eventually demonstrate how printed neighborhoods can offer an avenue to affordable housing to address homelessness in the region.

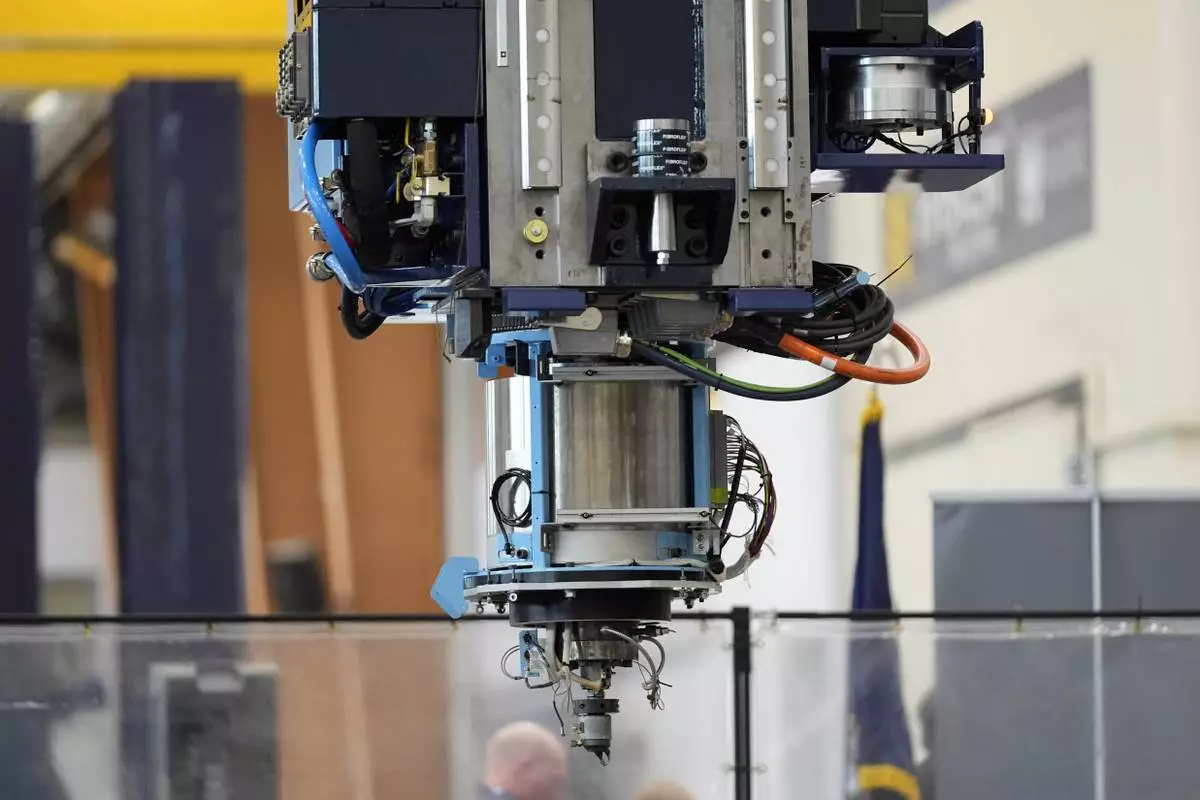

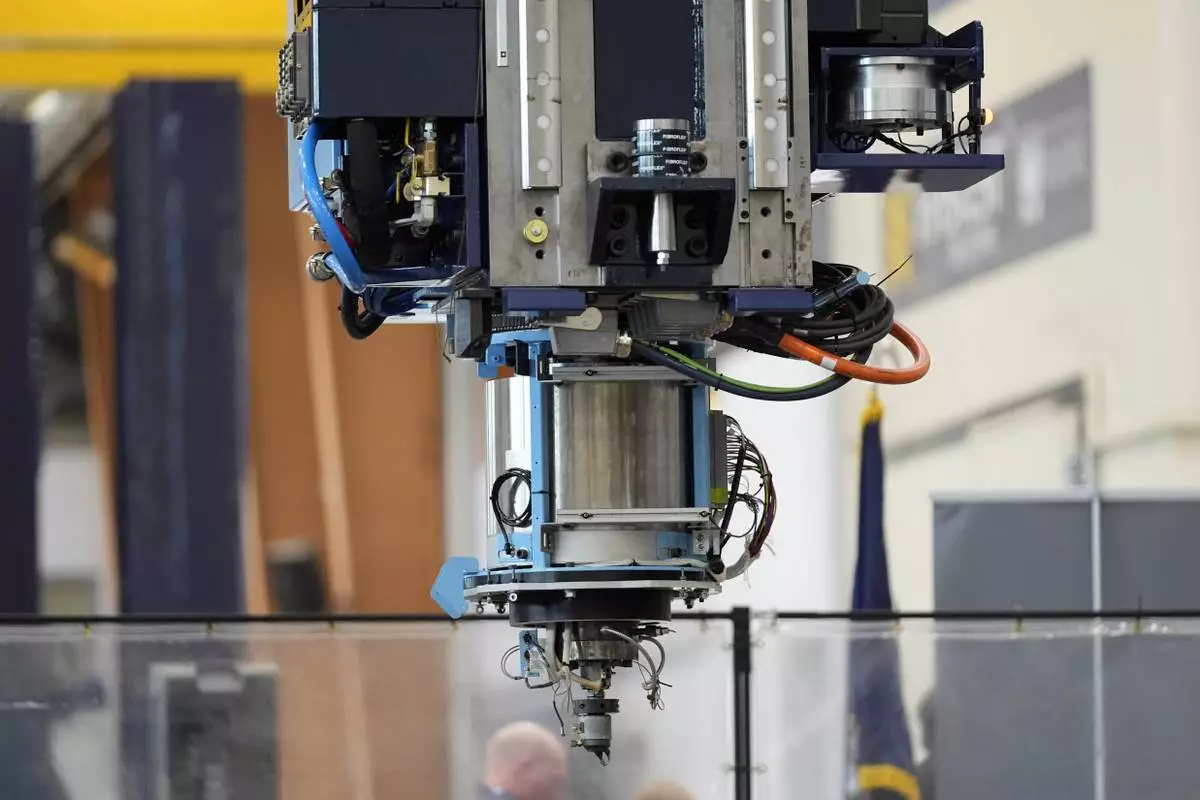

Thermoplastic polymers are extruded from a printer dubbed the “Factory of the Future 1.0." There could be even larger printers after the University of Maine breaks ground this summer on a new building, a spokesperson said.

The massive printer “opens up new research frontiers to integrate these collaborative robotics operations at a very large scale with new sensors, high-performance computing and artificial intelligence,” said Habib Dagher, director of UMaine’s Advanced Structures & Composite Center, where both of the printers are located.

Those attending the event included representatives from departments of defense, energy and housing, as well as other stakeholders who plan to utilize the new technologies made available by the printer. Heidi Shyu, under secretary of defense for research and engineering, said the printer "stands as a beacon of innovation."

The printer's frame fills up the large building in which it’s housed on the UMaine campus, and can print objects 96 feet long by 32 feet wide by 18 feet high (29 meters by 10 meters by 5.5 meters).

It has a voracious appetite, consuming as much as 500 pounds (227 kilograms) of material per hour.

The original printer, christened in 2019, was certified by Guinness World Records as the world’s largest polymer 3D printer, the university said. It was used to create a 600-square-foot, single-family home made of wood fiber and bio-resin materials that are recyclable. Dubbed “BioHome3D," it showed an ability to quickly produce homes. To meet the growing demand for housing, Maine alone will need another 80,000 homes over the next six years, according to MaineHousing.

Dagher said there's a shortage of both affordable housing and workers to build homes. The university wants to show how homes can be constructed nearly entirely by a printer with a lower carbon footprint. The buildings and construction sector accounts for roughly 37% of global greenhouse gas emissions, largely due to the production and use of materials such as cement, steel and aluminum that have a significant carbon footprint, according to the United Nations Environment Programme.

Such printed buildings can be recycled, which is unique compared to current construction. “You can basically deconstruct it, you can grind it up if you wish, the 3D printed parts, and reprint with them, do it again,” Dagher said before the event.

“It’s not about building a cheap house or a biohome,” he added, referring to the first 3D-printed house made entirely with bio-based materials. “We wanted to build a house that people would say, ‘Wow, I really want to live there.’”

Looking ahead, researchers plan to tinker with the material consumed by the machine, including more bio-based feedstocks from wood residuals that are abundant in Maine, the nation’s most heavily forested state.

But it can be used for a variety of other creations and already has been used for a range of things, from boats to defense department structures. In the past, the university showed off a 25-foot boat created by the first printer.

As for the original 3D printer, it isn't going away. The two printers can be used in concert to streamline manufacturing by working on the same project — or even part if necessary — and there will be even more of them working together in the future, officials said.

McDermott reported from Providence, Rhode Island.

Habib Dasher, director of UMaine's Advanced Structures & Composite Center, speaks at the unveiling of the world's largest 3D printer, Tuesday, April 23, 2024, at the University of Maine, in Orono, Maine. (AP Photo/Robert F. Bukaty)

The BioHome3D is seen Tuesday, April 23, 2024, at the University of Maine, in Orono, Maine. The 600-square-foot single-family home was made by UMaine's original 3D printer in 2019. (AP Photo/Robert F. Bukaty)

The world's largest 3D printer is seen Tuesday, April 23, 2024, at the University of Maine, in Orono, Maine. (AP Photo/Robert F. Bukaty)

The world's largest 3D printer is seen Tuesday, April 23, 2024, at the University of Maine, in Orono, Maine. (AP Photo/Robert F. Bukaty)

The University of Maine's first 3D printed home sits on Oct. 12, 2023, in Orono, Maine. The printer that created the house can cut construction time and labor. An even larger printer unveiled on Tuesday, April 23, 2024, may one day create entire neighborhoods. (AP Photo/Kevin Bennett)

A cross section of an exterior wall of a house is being printed on a 3D printer at the University of Maine's Advanced Structures & Composite Center on Oct. 12, 2023, in Orono, Maine. An even larger printer unveiled on Tuesday, April 23, 2024, may one day create entire neighborhoods. (AP Photo/Kevin Bennett)

A bed sits inside the University of Maine's first 3D printed home on Oct. 12, 2023, in Orono, Maine. The printer that created the house can cut construction time and labor. An even larger printer unveiled on Tuesday, April 23, 2024, may one day create entire neighborhoods. (AP Photo/Kevin Bennett)

The inside of the University of Maine's first 3D printed home is visible on Oct. 12, 2023, in Orono, Maine. The printer that created the house can cut construction time and labor. An even larger printer unveiled on Tuesday, April 23, 2024, may one day create entire neighborhoods. (AP Photo/Kevin Bennett)