Feature · News

BP China Insight: China's market becomes key — U.S. allies voting with their feet

No escape for those who endanger China's national sovereignty, security: spokeswoman

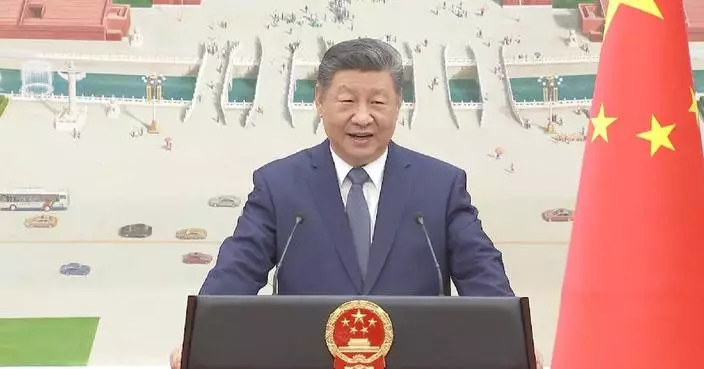

Canadian PM arrives in Beijing for official visit

The Chinese New Year Fireworks Display, Solely Sponsored by The Hong Kong Jockey Club, will Shine on the Victoria Harbour on February 18th

Sound, stable China-Canada ties serves common interests of both countries: Xi

China has no need or intent to use currency depreciation for trade advantage: central bank

BP China Insight: Japan wants to launch a deep-sea rare earth mining plan. Will it succeed?

BP China Insight: Expert: "De-Sinicization" has turned into "De-Americanization"

China's aggregate social financing maintains high growth in 2025

Canadian PM's visit to China paves way for more pragmatic trade ties: scholar

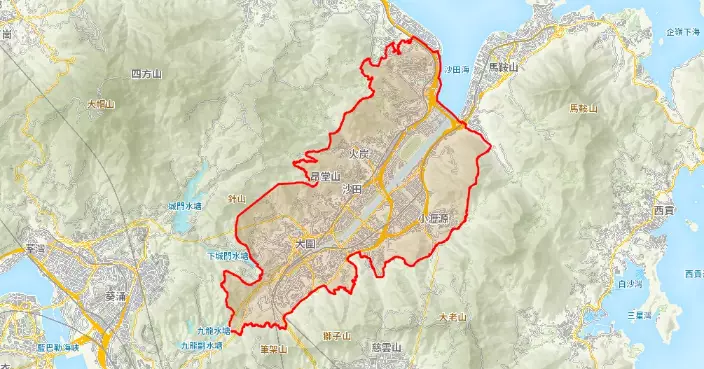

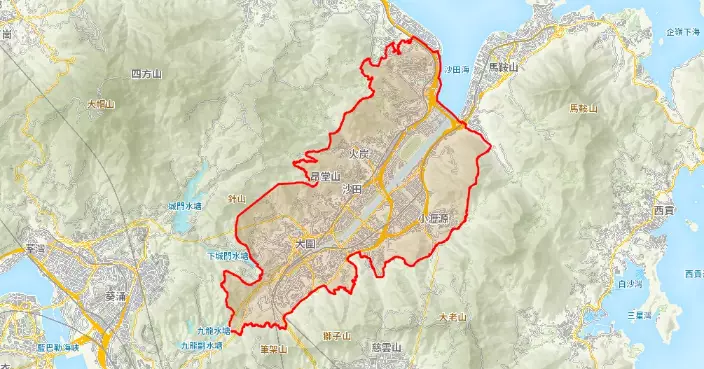

Sha Tin Outline Zoning Plan Amendments Announced by Town Planning Board

Six Beaches Rated Good for Swimming in Latest Water Quality Assessment

UN must resolutely defend victorious outcomes of World War II: Chinese envoy

Winter storm slams Toronto, closes schools, disrupts traffic

A Man Brandishing a Knife Took a Female Passerby Hostage at Tuen Mun Town Plaza, Police Arrived at the Scene and Fired Shots to Subdue Him

Chinese yuan weakens to 7.0078 against USD Friday

BP China Insight: Japan wants to launch a deep-sea rare earth mining plan. Will it succeed?

BP China Insight: Expert: "De-Sinicization" has turned into "De-Americanization"

China's aggregate social financing maintains high growth in 2025

Canadian PM's visit to China paves way for more pragmatic trade ties: scholar

BP China Insight: China's market becomes key — U.S. allies voting with their feet

No escape for those who endanger China's national sovereignty, security: spokeswoman

Canadian PM arrives in Beijing for official visit

The Chinese New Year Fireworks Display, Solely Sponsored by The Hong Kong Jockey Club, will Shine on the Victoria Harbour on February 18th

Sound, stable China-Canada ties serves common interests of both countries: Xi

China has no need or intent to use currency depreciation for trade advantage: central bank

Sha Tin Outline Zoning Plan Amendments Announced by Town Planning Board

Six Beaches Rated Good for Swimming in Latest Water Quality Assessment

UN must resolutely defend victorious outcomes of World War II: Chinese envoy

Winter storm slams Toronto, closes schools, disrupts traffic

A Man Brandishing a Knife Took a Female Passerby Hostage at Tuen Mun Town Plaza, Police Arrived at the Scene and Fired Shots to Subdue Him

Chinese yuan weakens to 7.0078 against USD Friday

Feature·Bloggers

【Deep Throat】Trump's Latest Iran Tariff Bluff: China Sees Right Through It

【Ariel】Jimmy Lai’s “Solitary” Twist: Judges Say He Asked For It

【What Say You?】Accomplice Witness Chen Zihao: Family Stalked, Fears Black Bloc Revenge After Release

【Deep Blue】International Laws? You Kidding Me?

【Bastille Commentary】Chicken-hearted Conservatives: Sanctioning Hong Kong Judges While Trump Runs Wild

【What Say You?】Trump’s “Maduro Grab” Gets a Glossy Spin by the Usual Suspects

The Latest: Middle East allies urge Trump to hold off on Iran strikes, diplomat says

- Trump says he may punish countries with tariffs if they don’t back the US controlling Greenland

- The Education Department is opening fewer sexual violence investigations as Trump dismantles it

- A hard-line cleric in Iran calls for executions over protests, a red line for Trump

- Cuba launches mass demonstration to decry US attack on Venezuela and demand Maduro's release

- KRISPY KREME® Helping Fans Level up Monday’s Football Festivities With Limited-Edition Championship Dozen, Available Monday, Jan. 19

- South Africa investigates Iran's participation in naval drills off its coast after US criticism

- White Castle Launches Early 2026 Deals Focused on Flavor, Value and Convenience

- How the Trump administration erased centuries of Justice Department experience

- Boston Legacy FC Signs Back-of-Kit Partnership with Voya Financial

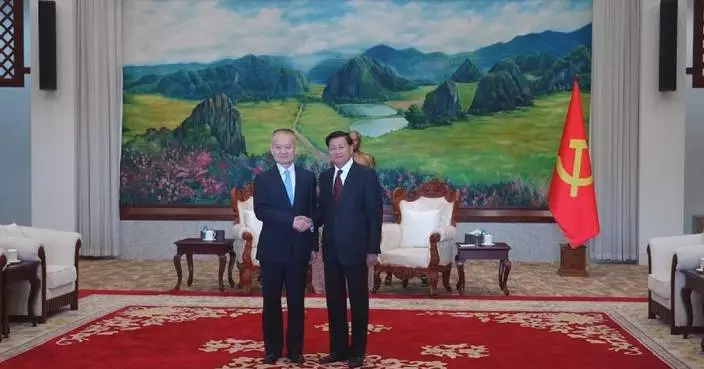

China, Canada should work together for stable, healthy, sustainable economic ties: Vice Premier

- Chinese premier chairs meeting on promoting service consumption

- Palestinian death toll in Gaza rises to 71,455

- ROK ex-president Yoon sentenced to 5 years in prison on arrest obstruction charges

- Mainland never slackens efforts to punish Taiwan separatists: commentary

- China's first light sport aircraft with independently-developed avionics, engine delivered

- Chinese stock markets edge lower Friday amid absence of major market-moving catalysts: analyst

- Hong Kong stock markets edge lower as Tokyo stocks decline amid policy uncertainty: analyst

- Families flee from homes in southern Lebanon as Israeli airstrikes level residential buildings, shops

- China launches coking coal options

Award Ceremony for 2025 Yiwugo's Top 10 Vendors Competition Successfully Held

- WebX Launches Global Chain Commerce Platform and Unveils Chain Capital in Hong Kong

- VEVOR Enters U.S. Physical Retail with First Brick-and-Mortar Store in Houston

- THIRDREALITY CES 2026 Recap: Real Stories, Real Homes, and What Comes Next

- Legal questions swirl around FDA's new expedited drug program, including who should sign off

- Takeaways from the AP's report on turmoil surrounding the FDA's new fast-track drug program

- NUH INAUGURATES NEW CENTRE TO ADVANCE PREDICTIVE AND ACCESSIBLE CARE FOR DIGESTIVE HEALTH

- MILESEEY GOLF to Unveil GeneSonic Pro at PGA Show 2026

- "Grand Sale Bazaar 2026" Officially Opens

- RoboSense Ranked No.1 in Global 3D LiDAR Sales Volume for Robotic Lawn Mowers

She set a photo afire, lit a cigarette — and became a symbol of resistance for Iran protesters

- What you need to know about Grok and the controversies surrounding it

- At Detroit auto show, spotlight dims for EVs

- Kaiser affiliates will pay $556M to settle a lawsuit alleging Medicare fraud

- What to know about UK legal changes aiming to regulate AI-generated nude images

- Ailing astronaut returns to Earth early in NASA's first medical evacuation

- Aimed at the growing number of young Chinese who live alone, a new app asks: ‘Are you dead?'

- Wikipedia unveils new AI licensing deals as it marks 25th birthday

- Grok blocked from undressing images in places where it's illegal, X says

- NASA sends 4 astronauts back to Earth in first medical evacuation

Tears and anger in Europe as exiled Iranians protest government crackdown

- Julio Iglesias denies sexual abuse allegations, calling them 'absolutely untrue'

- Kathleen Kennedy, steward of 'Star Wars,' steps down from Lucasfilm

- Former Universal chair David Linde named CEO of Sundance Institute

- The new BTS album title and what to know about the K-pop band’s comeback

- Min Jin Lee's 'Pachinko' follow-up, 'American Hagwon,' will explore Korean education obsession

- Actor Timothy Busfield ordered held without bond in New Mexico child sex abuse case

- Royal Opera sees generation change as Jakub Hrůša and Speranza Scappucci come in

- Julio Iglesias accused of sexual assault in Caribbean as Spanish prosecutors study the allegations

- Fanatics debuts Fanatics Studios with Olympics, Tom Brady and ESPN at Intuit Dome

Man City close to buying Guehi and manager Glasner announces he is leaving Crystal Palace in summer

- Britain's Matt Weston, Belgium's Kim Meylemans clinch World Cup skeleton season titles

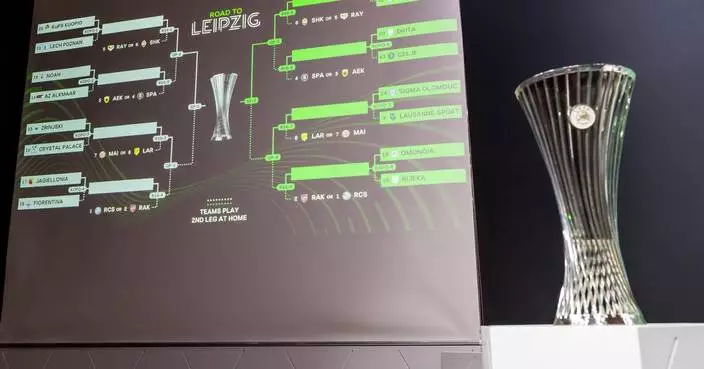

- Crystal Palace and Fiorentina will head east after Conference League knockout playoffs draw

- The road back to title contention was long for Miami. The Hurricanes have finally broken through

- At a war-ravaged sports center in Ukraine, the hope for Olympic glory persists

- Giovanni Franzoni's win in Wengen super-G makes him an Olympic contender for host Italy

- Has figure skating reached the limits of human performance?

- Photos show Ukraine's historic center in ruins but children, athletes still train ahead of Olympics

- John Harbaugh's mentor, Andy Reid, had a better second act than his first

- Madison Keys pictures herself as a champion again at the Australian Open

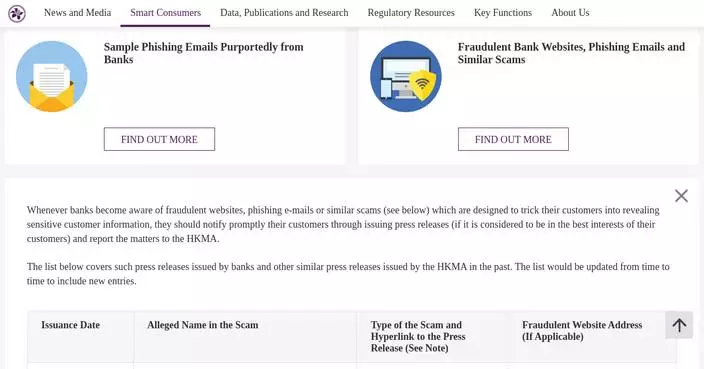

HKMA Warns Public About Recent Banking Scams and Fraudulent Websites

- Two Passengers Imprisoned for Smuggling Duty-Not-Paid Cigarettes at Lo Wu Control Point

- HKFI Cocktail Party 2026: Celebrating Unity and Growth in Hong Kong's Insurance Sector

- Two men sentenced for unauthorized transfer of sports facility bookings, facing 80 hours of community service.

- Labour Department Launches Good Employer Charter 2026 to Promote Work-Life Balance and Family-Friendly Practices.

- New Melioidosis Case in Hong Kong: Public Urged to Maintain Hygiene After Recent Storms

- Hong Kong Launches Port Community System for Smarter, Integrated Maritime Operations

- Government Proposes Bill to Enhance Medical Council's Complaint Handling in Hong Kong

- Sick 70-Year-Old In Custody Dies After Deteriorating Condition in Public Hospital

- Health Authorities Warn of Rising Dengue and Chikungunya Fever Risks Amid Favorable Mosquito Breeding Conditions

China promotes 25 measures nationwide to facilitate cross-border trade

- Cave-training enables astronauts to better endure extreme environments

- Former Slovenian president urges European unity on Greenland

- Iran diplomat claims unrest under control, blames US-Israel plot

- China's giant radio telescope observations unravel origin of cosmic enigmatic flashes

- Türkiye opposes military operation against Iran, says FM

- AIIB grants 70 bln USD funding in 10 years

- China, Canada should deepen cooperation to unleash potential of complementary economies: expert

- U.S. stocks close higher as chip, financial stocks rally

- U.S. dollar ticks up

Category · News

The Latest: Middle East allies urge Trump to hold off on Iran strikes, diplomat says

Trump says he may punish countries with tariffs if they don’t back the US controlling Greenland

The Education Department is opening fewer sexual violence investigations as Trump dismantles it

A hard-line cleric in Iran calls for executions over protests, a red line for Trump

Award Ceremony for 2025 Yiwugo's Top 10 Vendors Competition Successfully Held

Cuba launches mass demonstration to decry US attack on Venezuela and demand Maduro's release

KRISPY KREME® Helping Fans Level up Monday’s Football Festivities With Limited-Edition Championship Dozen, Available Monday, Jan. 19

South Africa investigates Iran's participation in naval drills off its coast after US criticism

White Castle Launches Early 2026 Deals Focused on Flavor, Value and Convenience

How the Trump administration erased centuries of Justice Department experience

Boston Legacy FC Signs Back-of-Kit Partnership with Voya Financial

Man City close to buying Guehi and manager Glasner announces he is leaving Crystal Palace in summer

WebX Launches Global Chain Commerce Platform and Unveils Chain Capital in Hong Kong

VASA Fitness Opens Eighteenth Club in Colorado, Expanding Access to High-Value Fitness in the State

VEVOR Enters U.S. Physical Retail with First Brick-and-Mortar Store in Houston

THIRDREALITY CES 2026 Recap: Real Stories, Real Homes, and What Comes Next

Britain's Matt Weston, Belgium's Kim Meylemans clinch World Cup skeleton season titles

When Texas Republican John Cornyn became a senator, Bush was president. Will he survive Trump's GOP?

Trump isn't waiting for future generations to name things after him. It's happening now

Legal questions swirl around FDA's new expedited drug program, including who should sign off

Takeaways from the AP's report on turmoil surrounding the FDA's new fast-track drug program

Crystal Palace and Fiorentina will head east after Conference League knockout playoffs draw

China, Canada should work together for stable, healthy, sustainable economic ties: Vice Premier

The road back to title contention was long for Miami. The Hurricanes have finally broken through

Chinese premier chairs meeting on promoting service consumption

She set a photo afire, lit a cigarette — and became a symbol of resistance for Iran protesters

At a war-ravaged sports center in Ukraine, the hope for Olympic glory persists

A South Korean court sentences Yoon to 5 years in prison on charges related to martial law decree

Walmart Announces Leadership Changes

MILESEEY GOLF to Unveil GeneSonic Pro at PGA Show 2026

NUH INAUGURATES NEW CENTRE TO ADVANCE PREDICTIVE AND ACCESSIBLE CARE FOR DIGESTIVE HEALTH

Giovanni Franzoni's win in Wengen super-G makes him an Olympic contender for host Italy

"Grand Sale Bazaar 2026" Officially Opens

Photos show voters going to the polls in Uganda's presidential election

Uganda's president leads in tense election marred by internet shutdown and voting interference

Tears and anger in Europe as exiled Iranians protest government crackdown

Palestinian death toll in Gaza rises to 71,455

Ukraine’s battered power grid faces unprecedented challenge, energy minister says

More than 100 dead in torrential rain and floods across southern Africa

Henderson Brothers Announces Executive Successions, Adds New Employee Shareholders

Russian court considers central bank's $232B lawsuit against Euroclear over seized assets

Has figure skating reached the limits of human performance?

ROK ex-president Yoon sentenced to 5 years in prison on arrest obstruction charges

RoboSense Ranked No.1 in Global 3D LiDAR Sales Volume for Robotic Lawn Mowers

Mantle to Introduce New RWA Trading Capabilities and Sports Fan Economies with Fluxion, VOOI, SCOR in Upcoming Jan Livestream

Global Economic Cooperation 2026 to Explore New Pathways for Cooperation, Growth and Resilience in a Multipolar World

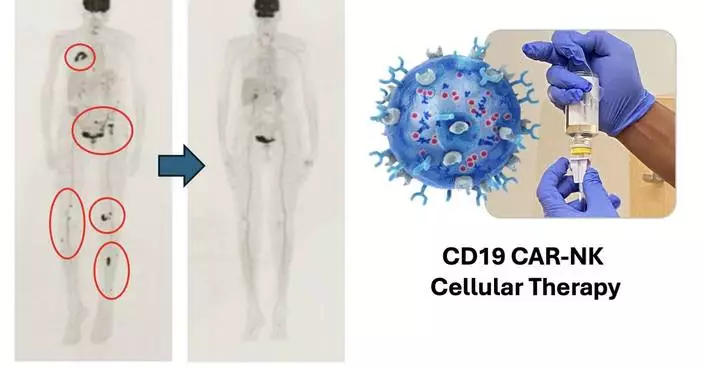

ImmunityBio Announces Durable Complete Response of 15 Months with a Chemotherapy-Free CD19 CAR-NK Cell Therapy in Waldenstrom Lymphoma

AST SpaceMobile Awarded Prime Contract Position on U.S. Missile Defense Agency SHIELD Program

Essential Utilities Elevates Alexis Rodriguez to Vice President of Strategy and Corporate Development

Jointly Charging the Road Ahead | Huawei Releases Top 10 Trends of Charging Network Industry 2026

Fire breaks out in one of Seoul's last-remaining shanty towns

In their words: Greenlanders talk about Trump's desire to own their Arctic island

BingX Becomes Scuderia Ferrari HP's First-Ever Crypto Exchange Partner

HKMA Warns Public About Recent Banking Scams and Fraudulent Websites

Photos show Ukraine's historic center in ruins but children, athletes still train ahead of Olympics

Bybit CEO Ben Zhou to Unveil 2026 Roadmap in Keynote Heralding New Era for Digital Finance

Two Passengers Imprisoned for Smuggling Duty-Not-Paid Cigarettes at Lo Wu Control Point

Photos show daily life along Venezuela’s oil coast after Maduro’s capture

HKFI Cocktail Party 2026: Celebrating Unity and Growth in Hong Kong's Insurance Sector

Maxine Gellens of Berkshire Hathaway HomeServices California Properties Successfully Assists Buyer and Seller of $18 Million La Jolla Estate

Audi Revolut F1 Team Welcomes Nexo as Official Digital Asset Partner

John Harbaugh's mentor, Andy Reid, had a better second act than his first

USI Subsidiary Universal Optoelectronics Acquires Controlling Stake in Eugenlight Technologies, Advancing Optical Interconnect Industry Integration

Canada agrees to cut tariff on Chinese EVs in return for lower tariffs on Canadian farm products

Two men sentenced for unauthorized transfer of sports facility bookings, facing 80 hours of community service.

Labour Department Launches Good Employer Charter 2026 to Promote Work-Life Balance and Family-Friendly Practices.

In Spain, Venezuelan migrants balance hope and fear about their country's future

Metis "Starry Pro": Achieving Greater Wealth Stability in a Changing Landscape.

At top UN court, Myanmar denies deadly Rohingya campaign amounts to genocide

New Melioidosis Case in Hong Kong: Public Urged to Maintain Hygiene After Recent Storms

Julio Iglesias denies sexual abuse allegations, calling them 'absolutely untrue'

Hong Kong Launches Port Community System for Smarter, Integrated Maritime Operations

Mainland never slackens efforts to punish Taiwan separatists: commentary

KuCoin Ranks Among Top Three Exchanges by Market Share Growth in TokenInsight's 2025 Annual Report

Government Proposes Bill to Enhance Medical Council's Complaint Handling in Hong Kong

Madison Keys pictures herself as a champion again at the Australian Open

China's first light sport aircraft with independently-developed avionics, engine delivered

Chinese stock markets edge lower Friday amid absence of major market-moving catalysts: analyst

Hong Kong stock markets edge lower as Tokyo stocks decline amid policy uncertainty: analyst

Infinix Wins Multiple "Best of CES 2026" Awards for Satellite Communication and Breakthrough Innovations

Sick 70-Year-Old In Custody Dies After Deteriorating Condition in Public Hospital

Families flee from homes in southern Lebanon as Israeli airstrikes level residential buildings, shops

China launches coking coal options

Health Authorities Warn of Rising Dengue and Chikungunya Fever Risks Amid Favorable Mosquito Breeding Conditions