Vertically integrated production and precision processes help lower costs, simplify logistics and reduce development time

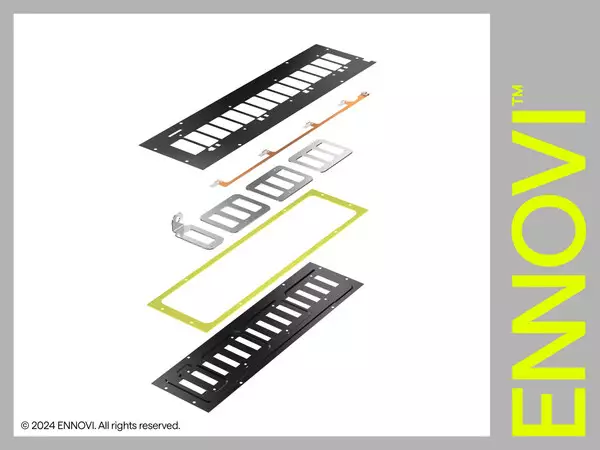

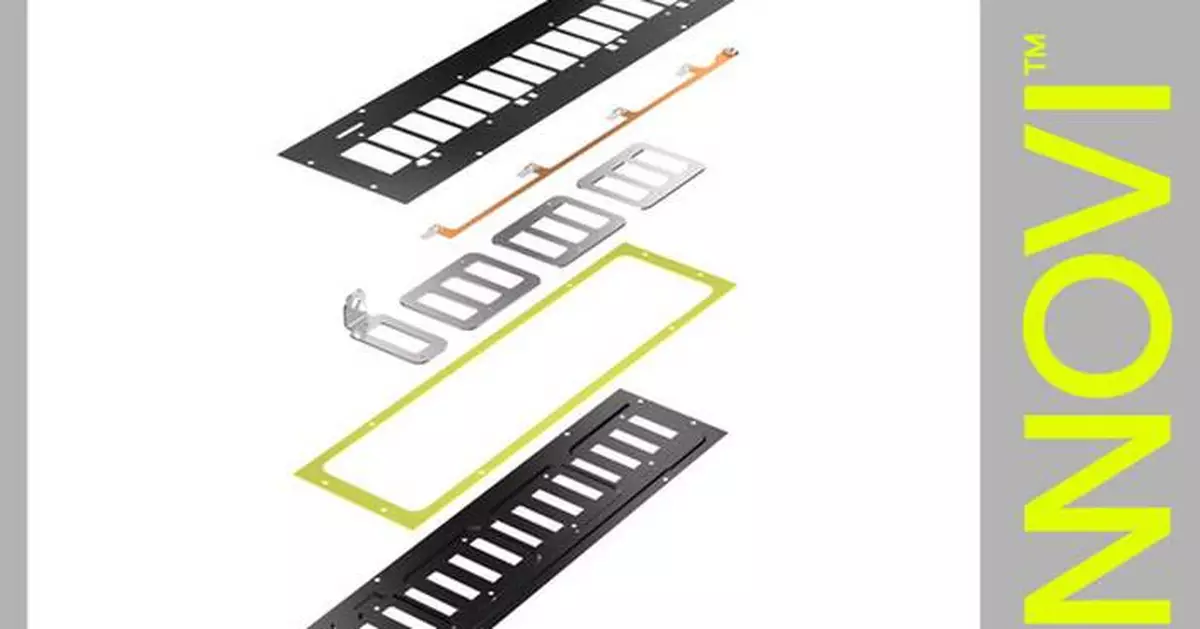

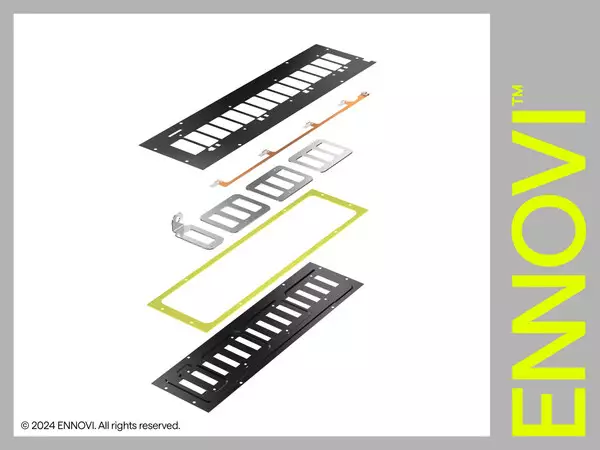

SINGAPORE, Oct. 7, 2024 /PRNewswire/ -- ENNOVI, a mobility electrification solutions partner, augments its prismatic and cylindrical battery cell contacting systems with the launch of ENNOVI-CellConnect-Pouch. Designed for the battery manufacturers favoring the pouch cell form factor, the new cell contacting system prioritizes cost-effectiveness with our FDC technologies, faster manufacturing cycle time, and aids the fast release of gasses produced during a thermal event.

"With the ENNOVI-CellConnect-Pouch cell contacting system we offer battery manufacturers a total vertically integrated production solution enabling us to produce a part at a lower cycle time using hot lamination," says Gustavo Cibrian, Product Manager, ENNOVI. "The system's design removes the need for traditional plastic cell carriers, made out of glass-reinforced plastic, and eliminates the carrier storage and molding lines, and heat staking process."

ENNOVI's advanced lamination technology ensures the structural integrity and durability of the battery pack. Utilizing flexible die-cut circuit (FDC) technology for the low voltage signal traces, instead of a conventional flexible printed circuit (FPC), reduces production time and costs while minimizing environmental impact.

The upper dielectric layer incorporates the FDC copper traces, while the lower layer is pre-cut to the shape of the current collectors. Both layers are made of automotive-grade PI or PET material with good electrical insulation and temperature stability properties. The two layers are laminated together with all built-in fuse traces or surface mount fuses and NTC temperature sensors layered in between, streamlining material usage and creating a thin design. The overall design also helps mitigate battery thermal runaway by achieving a fast exhaust release time.

For more information about ENNOVI-CellConnect-Pouch, please visit ennovi.com/cell-contacting-system-pouch.

About ENNOVI:

At ENNOVI we design and manufacture products and solutions for electrical battery platform developments, power components, and signal interconnect design solutions. Using our decades of experience in electro-mechanical engineering and high-precision manufacturing, we work with EV OEMs and suppliers to bring their ideas to life. As a Mobility Electrification Solutions Partner, we accelerate the process for our EV customers by offering complete end-to-end manufacturing capabilities from R&D, design, tooling to production. Learn more at www.ennovi.com.

Press Contacts:

Selvan Wilhelm

Selvan.Wilhelm@ennovi.com

Erin McMahon

erin.mcmahon@publitek.com

Publitek Germany

Alessandra Rosati

alessandra.rosati@publitek.com

** The press release content is from PR Newswire. Bastille Post is not involved in its creation. **

ENNOVI Revolutionizes Pouch Cell Battery Design with the Introduction of ENNOVI-CellConnect-Pouch

Reconfiguration of Full-stack Capabilities to Restructure Embodied Intelligent Ecosystem

LAS VEGAS, Jan. 8, 2026 /PRNewswire/ -- Salcomp, the leading global intelligent manufacturing enterprise, is showcasing its complete humanoid robot technology matrix of 'core components - hardware manufacturing - scenario implementation' at Booth #11014 during CES 2026, held from January 6 to 9 in Las Vegas.

This time Salcomp is demonstrating its strategic determination to 'challenge the top 3 intelligent hardware manufacturers in the world', injecting strong impetus into the global development of physical intelligent industries.

Based on the profound precision manufacturing experience accumulated in the consumer electronics field, Salcomp has established a complete technical chain covering core components of robots, assembly research and development, as well as the implementation of industrial scenarios. During this exhibition, the company clearly conveyed its core service positioning to the global market: providing comprehensive component processing services for robots related to embodied intelligence, as well as integrated services including ODM design, processing, assembly, and testing for complete machines.

In terms of scale production capacity and delivery capability, Salcomp has established a solid barrier. As of now, the company has completed over 5,000 units of humanoid (embodied) robot hardware/complete machine assembly services, covering all core modules such as the entire machine, dexterous hands, and joint modules, and has verified its large-scale service capability through tangible delivery results.

In terms of production capacity layout, Salcomp has jointly established an embodied intelligent robot innovation center in October 2025. They will jointly build a pilot base for humanoid robots. This base has the capacity to produce 5,000 sets/y and can completely bridge the industrial gap from laboratory prototypes to large-scale production. According to the plan, the base will gradually be upgraded to a super factory for humanoid robots with an annual production capacity of 500,000 units in the future, continuously consolidating the advantage of large-scale delivery.

At this year's CES debut, Salcomp showcased its potential for mutual benefit with a triple advantage of "manufacturing strength, application understanding, and mass production guarantee" to global partners. In the future, the company will continue to deeply focus on the field of embodied intelligent hardware, using its full-stack service capabilities to help more enterprises accelerate technology implementation and product mass production, and drive the global embodied intelligent industry into a new stage of high-quality development.

About Salcomp

Founded in 1975, Salcomp is a premier manufacturer of chargers and adapters, specializing in power solutions for the mobile phone, tablet, and notebook PC industries. Trusted by many of the world's leading brands in these sectors, we have established ourselves as a preferred partner to top technology companies who rely on our products for their quality, reliability, and innovation.

In addition to our core markets, Salcomp is a well-established supplier across other selected segments and product categories, providing versatile power solutions that meet diverse industry needs. Our expertise and commitment to excellence enable us to support a broad range of applications, positioning us as a leader in the global power solutions landscape.

Media Contact:

Email: jingsong@lingyiitech.com

Tel: +86 15302721160

** The press release content is from PR Newswire. Bastille Post is not involved in its creation. **

Salcomp's Debut on CES 2026