CHICAGO--(BUSINESS WIRE)--Jan 22, 2025--

Dubai Design Week, the Middle East’s premier design event, served as the global stage for Mitsubishi Estate’s visionary 3D-printed teahouse. This groundbreaking creation seamlessly merged traditional Japanese culture and heritage with FDM 3D printing technology, offering a captivating showcase of architectural innovation. Dynamism played a key role in supporting the 3D printing of teahouse components, which were all done using a wood-based filament. These parts were then shipped to Dubai, where they were seamlessly assembled into the stunning final structure.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20250116842687/en/

Dubai Design Week: A Global Hub for Creativity

Dubai Design Week is renowned for uniting designers from around the world to inspire creativity and foster innovation. The annual event features exhibitions, pop-ups, installations, and talks that engage professionals, media, and design enthusiasts while strengthening Dubai’s reputation as a vibrant design capital.

The 3D-Printed Teahouse: Tradition Meets Innovation

The 3D-printed teahouse stood out as a beacon of innovation at Dubai Design Week. By merging traditional architecture with modern 3D printing, this ambitious project showcased how additive manufacturing can preserve cultural heritage while pushing the boundaries of design and engineering.

Traditional Japanese Engineering Influences

The teahouse design drew heavily from Japanese traditions, particularly the “hozo tsugi” joinery technique. This ancient method involves interlocking wooden joints without nails or screws, a skill-intensive practice that ensures durability and elegance. To recreate this authentically, Polywood —a wood-infused resin filament—was used to replicate the aesthetic of traditional Japanese tea rooms.

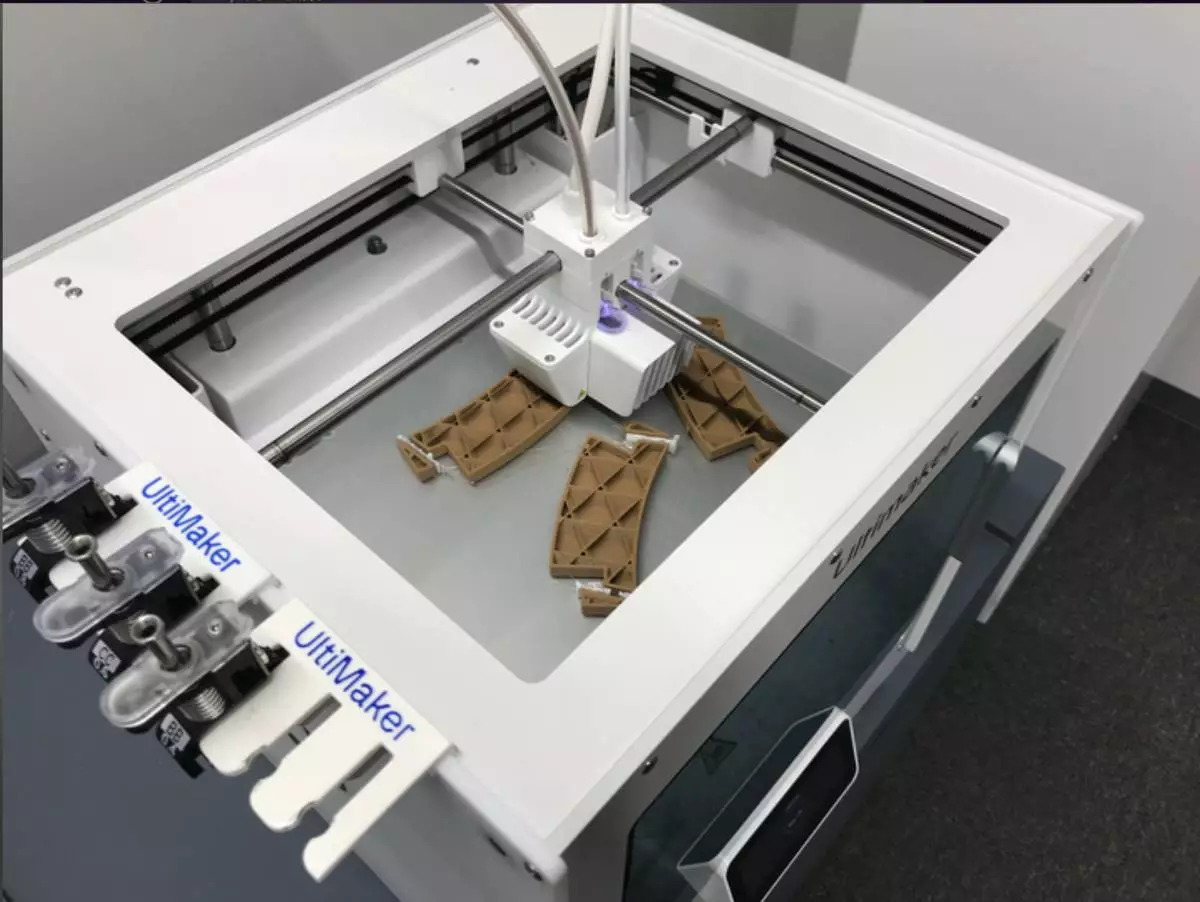

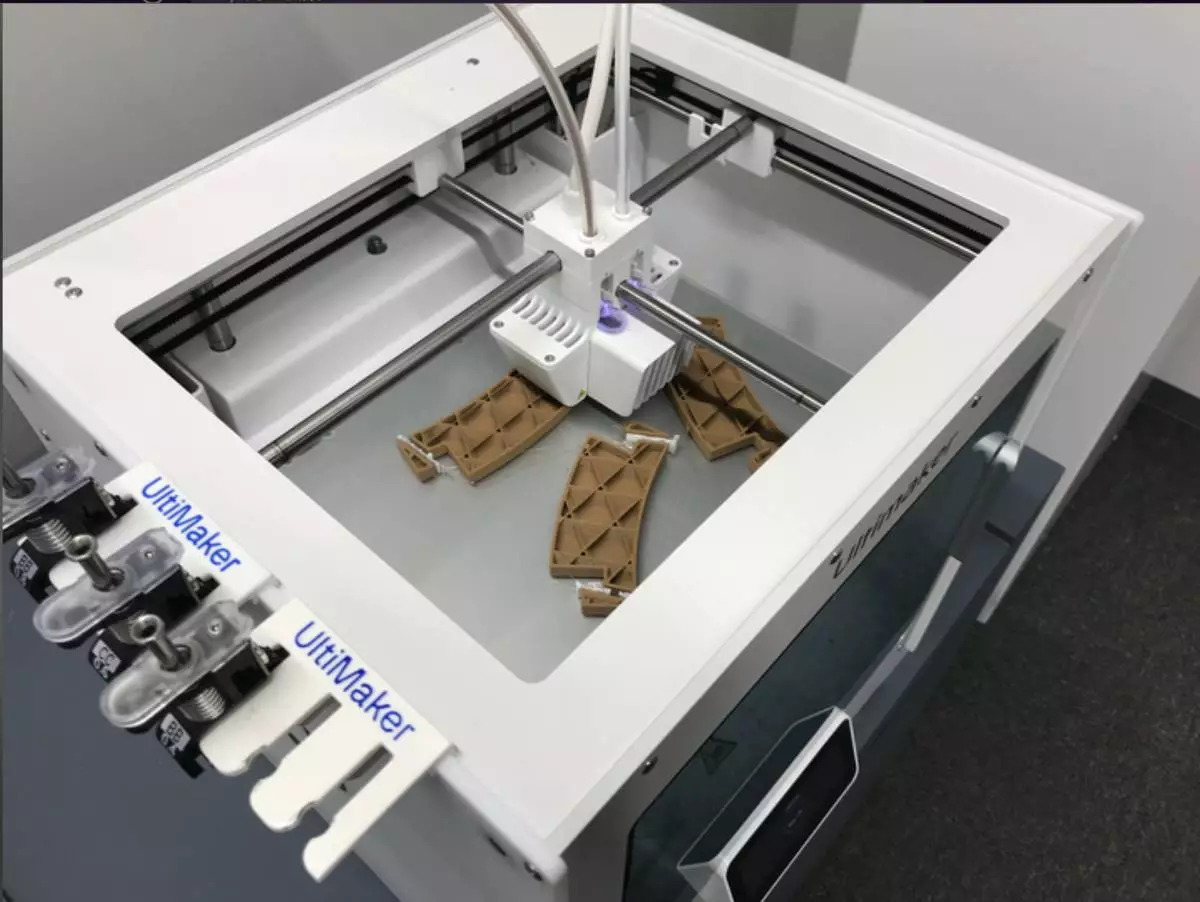

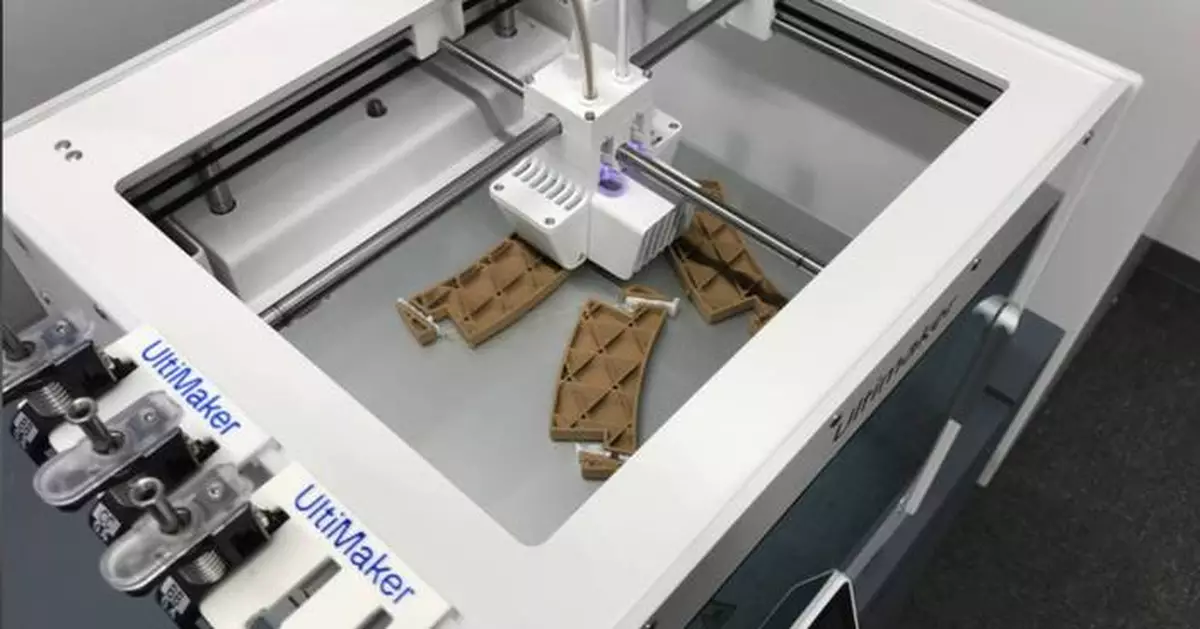

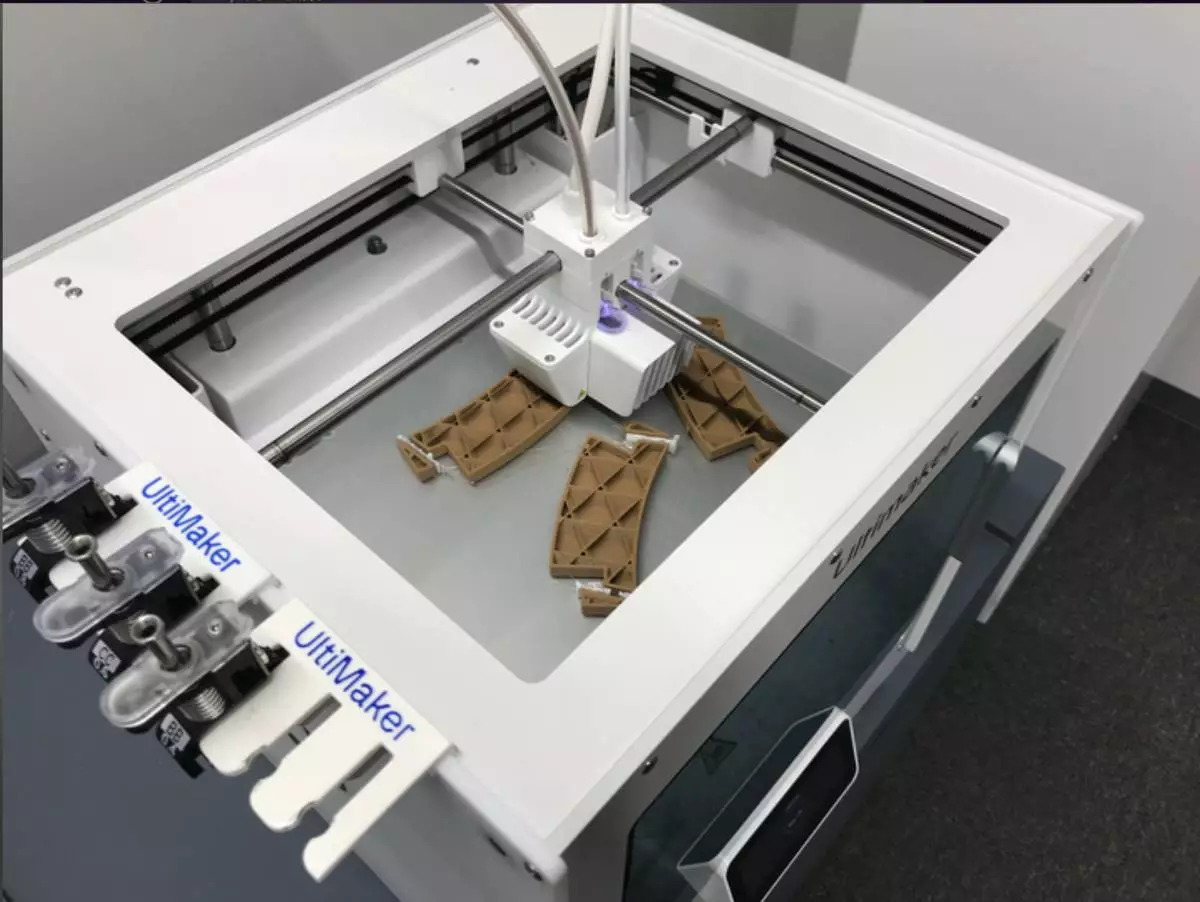

Ultimaker’s Role in Precision Printing

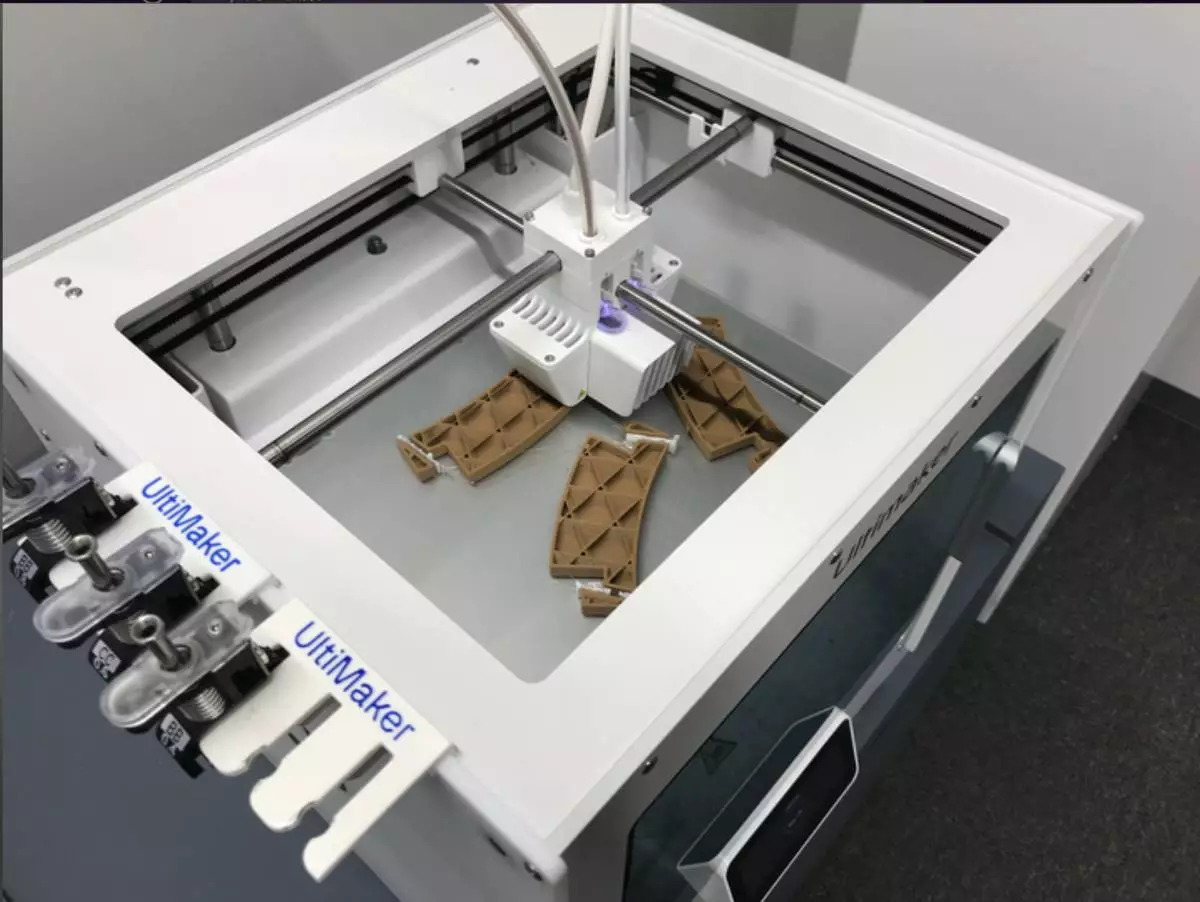

Key to the project’s success was Ultimaker’s S series 3D printers. Using digital renderings, the intricate teahouse design was divided into 988 individual parts, including 1,938 meticulously crafted “hozo” joints. The Ultimaker printers delivered unparalleled precision, completing approximately 4,000 hours of printing to bring the project to life. The printers’ versatility enabled the seamless integration of traditional engineering with advanced FDM printing techniques.

The Significance of the 3D-Printed Teahouse

The teahouse was more than an architectural marvel—it symbolized the harmonious blending of tradition and technology. Leveraging FDM printing, this demonstrated the transformative potential of additive manufacturing to preserve and reimagine cultural heritage. The teahouse captivated a global audience, underscoring the possibilities of 3D printing in architecture, design, and engineering.

Bridging Heritage and Innovation

Dynamism’s contribution to Dubai Design Week highlighted the growing role of 3D printing in modern design. Projects like the 3D-printed teahouse not only showcase the technological capabilities of FDM printing but also emphasize its power to honor and elevate tradition. As a leader in advanced 3D printing solutions, Dynamism continues to inspire by merging the past with the future through innovative designs.

The 3D-printed Teahouse fuses traditional Japanese culture with cutting-edge FDM 3D printing technology. Designed with precision and inspired by ancient 'hozo tsugi' joinery techniques, it illustrates how additive manufacturing preserves and reimagines traditional engineering techniques and architectural heritage. (Photo: Business Wire)

1,938 meticulously crafted “hozo” joints are printed on Ultimaker S series printers completing approximately 4,000 hours of printing to bring the project to life. (Photo: Business Wire)

LIMA, Peru (AP) — Peru’s Congress on Tuesday voted to remove interim President José Jerí from office, triggering fresh political instability just weeks before the nation’s April presidential election.

Jerí was Peru’s seventh president in less than a decade, and will now be replaced by a member of Congress, who will be expected to lead the country during the election and until the newly elected president is sworn in on July 28.

Jerí, a 39-year-old lawyer, was elected to Peru’s Congress in 2021 for Somos Peru, a small conservative party. He was the head of Peru’s Congress in October, when lawmakers voted to remove then President Dina Boluarte from office as the nation faced increasing rates of violent crime.

Following Boluarte’s removal, Jerí was elected by his peers as the nation’s interim president, with the expectation that he would stay in office until July, when a new presidential term begins. But his mandate was cut short as corruption allegations surfaced against him and Congress grew impatient with his leadership.

Jerí is facing a preliminary investigation for corruption and influence peddling launched by Peru’s Attorney General’s office earlier this year.

The charges stem from a series of undisclosed meetings with two Chinese businessmen in December. One of those businessmen holds active government contracts, while the other is under investigation for alleged involvement in an illegal logging operation.

Jerí has denied wrongdoing. He said he met the executives to organize a Peruvian-Chinese festivity, but his opponents have accused him of corruption.

While Jerí still hasn’t been found guilty of corruption, his former colleagues in Congress cited the allegations as one of the reasons to remove him, arguing that Jerí had become unfit to execute his presidential duties.

A clause in Peru’s constitution enables legislators to remove presidents who are found to be “morally incapable” of conducting their duties.

This clause has given legislators great leverage over Peru’s executive branch, which has also struggled in recent years to build congressional majorities.

The moral incapacity clause has been interpreted widely by legislators who have used it, along with corruption allegations, to remove presidents that no longer suit the interests of the nation’s political parties.

Peru has had seven presidents over the past decade — with only two of those elected by a popular vote. The others have been vice presidents who have stepped in for deposed presidents, and members of Congress who have been selected by their peers to lead the South American nation.

Despite the revolving door of presidents, Peru’s economy has been stable over the past decade, with governments sticking to orthodox economic policies that include modest fiscal spending.

The South American nation had a public debt to gross domestic product ratio of 32% in 2024, one of the lowest in Latin America, and has welcomed foreign investment in sectors like mining and infrastructure.

However, observers have noted that the nation’s increasingly powerful Congress has also passed legislation in recent years that threatens the independence of Peru’s judiciary.

Legislators will convene on Wednesday to elect a new interim president, who will be expected to stay in office until July and hand over power to the winner of the nation’s presidential elections, which are scheduled for April 12.

Rafael López Aliaga, a conservative businessman and former mayor of Lima is currently leading a crowded field of candidates that also includes former legislator Keiko Fujimori, a three time presidential candidate whose father was the nation’s president in the 1990s.

If no candidate gets more than 50% of the votes in the April election, there will be a runoff in June between the top two contenders.

Rueda reported from Bogota, Colombia.

Demonstrators celebrate after learning Congress voted to remove interim President Jose Jeri as he faces corruption allegations, outside the site where lawmakers met in Lima, Peru, Tuesday, Feb. 17, 2026. (AP Photo/Guadalupe Pardo)

Demonstrators celebrate after Congress voted to remove interim President Jose Jeri as he faces corruption allegations outside the site where lawmakers met in Lima, Peru, Tuesday, Feb. 17, 2026. (AP Photo/Guadalupe Pardo)

A demonstrator carries a fake coffin with a photo of interim President Jose Jeri after Congress voted to remove him, outside the site where lawmakers met in Lima, Peru, Tuesday, Feb. 17, 2026. (AP Photo/Guadalupe Pardo)

Photographed through a gate, Peru's President Jose Jeri, right, stands with Prime Minister Ernesto Alvarez during the changing of the guard ceremony at the government palace in Lima, Peru, Tuesday, Feb. 17, 2026. (AP Photo/Gerardo Marin)