HONG KONG, April 18, 2025 /PRNewswire/ -- The 3rd Hong Kong International Innovation and Technology Exhibition (InnoEX), co-organized by the Innovation, Technology and Industry Bureau of the HKSAR Government and the Hong Kong Trade Development Council (HKTDC), took place at the Hong Kong Convention and Exhibition Centre from April 13th to 16th. The event attracted over 2,800 exhibitors from 29 countries and regions, spotlighting innovations in low-altitude economy, intelligent mobility, AI, robotics, and cybersecurity. As a leading enterprise in smart construction solutions, MytePro showcased its AIoT-integrated Smart Workforce Management Platform at the exhibition.

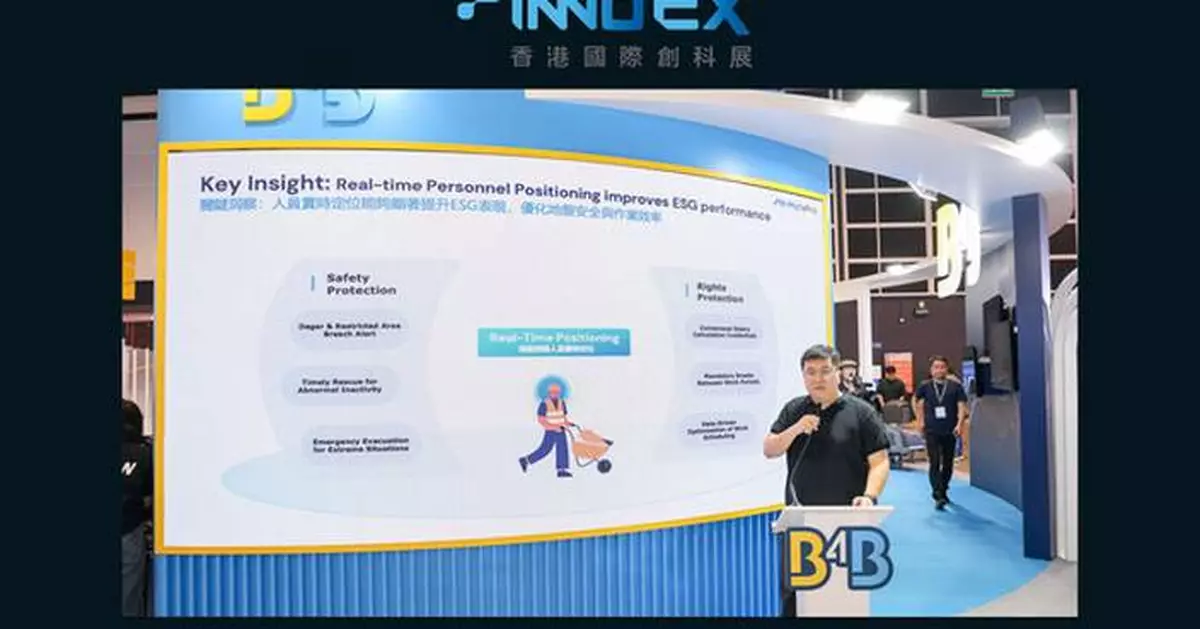

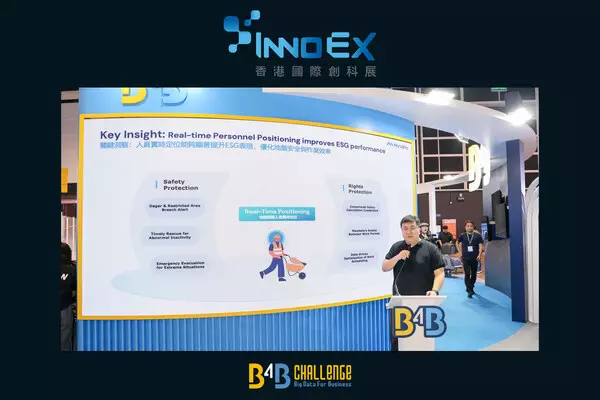

During the showcase, Leon Xiong, MytePro's Head of Overseas Product & R&D, underscored the persistent challenges in construction safety and labor rights. Industry data shows that construction sites account for over 70% of workplace fatalities, making them one of the most hazardous workplace. Traditional safety systems fall short: manual inspections often overlook violations, and the lack of digital records complicates incident tracing. These issues not only stunt the industry's sustainable growth but also escalate operational risks.

The new Smart Workforce Management Platform directly tackles these pain points while aligning with Hong Kong's 4S (Smart Site Safety System) policy for construction sites. It revolutionizes the industry across four key areas: safety, speed, satisfaction, sustainability.

Regarding safety, the platform uses real-time positioning and tracking to give managers instant insights into worker movements, optimizing workforce allocation and preventing project delays. Its intelligent worker-helmet matching enforces strict access control, keeping unauthorized personnel out of high-risk zones. The system triggers immediate alerts for hazardous situations like abnormal stationary periods, signal loss, or proximity to danger areas. In emergencies, features such as digital avatars, one-click recall, and guided evacuations integrate with the emergency command system, ensuring rapid response and minimizing losses.

When considering speed, powered by real-time positioning and smart scheduling, the platform streamlines personnel flow and task assignments on construction sites. This seamless coordination accelerates project timelines, reduces idle resources, and boosts overall execution efficiency.

With respect to satisfaction, the platform includes modules for accurate time tracking, overtime alerts, automated time sheet generation, and quick payroll processing to prioritize worker well-being. These features workers' rights, reduce labor disputes, enhance job satisfaction, and foster harmonious employment relationships.

From the sustainability standpoint, the platform lays a solid foundation for Hong Kong's construction industry to thrive sustainability systematically reducing accidents, improving efficiency, and safeguarding rights. It also propels the sector towards green, low-carbon operations.

At the event, MytePro was conferred the Best ESG Solutions Award 2025 in recognition of its groundbreaking initiatives within the ESG domain. Looking ahead, MytePro plans to deepen its presence in Hong Kong through closer collaborations with local construction firms. The company will continuously refine its product to adapt to the city's complex construction environment, aiding businesses in achieving safety, efficiency, and ESG goals. Building on its Hong Kong success, MytePro aims to expand globally, championing a future where construction is safer, more efficient, and eco-friendly, ultimately contributing to smarter living environment worldwide.

CONTACT: Valance Zhang, marketing@mytepro.com

** The press release content is from PR Newswire. Bastille Post is not involved in its creation. **

MytePro's Workforce Safety Solution Debuts at InnoEX 2025, Empowering ESG in Construction with AIoT