|

The contract is an important milestone strengthening HTS supply chain of the fusion industry

TOKYO, June 20, 2025 /PRNewswire/ -- Proxima Fusion and Faraday Factory Japan have signed a contract for the supply of high temperature superconducting (HTS) tape. This delivery will help the leading European stellarator developer Proxima Fusion to achieve its next milestone – a superconducting demo magnet.

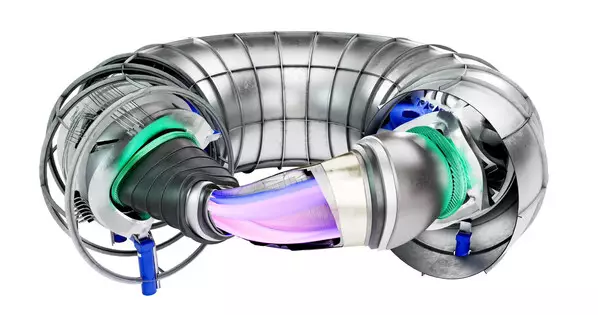

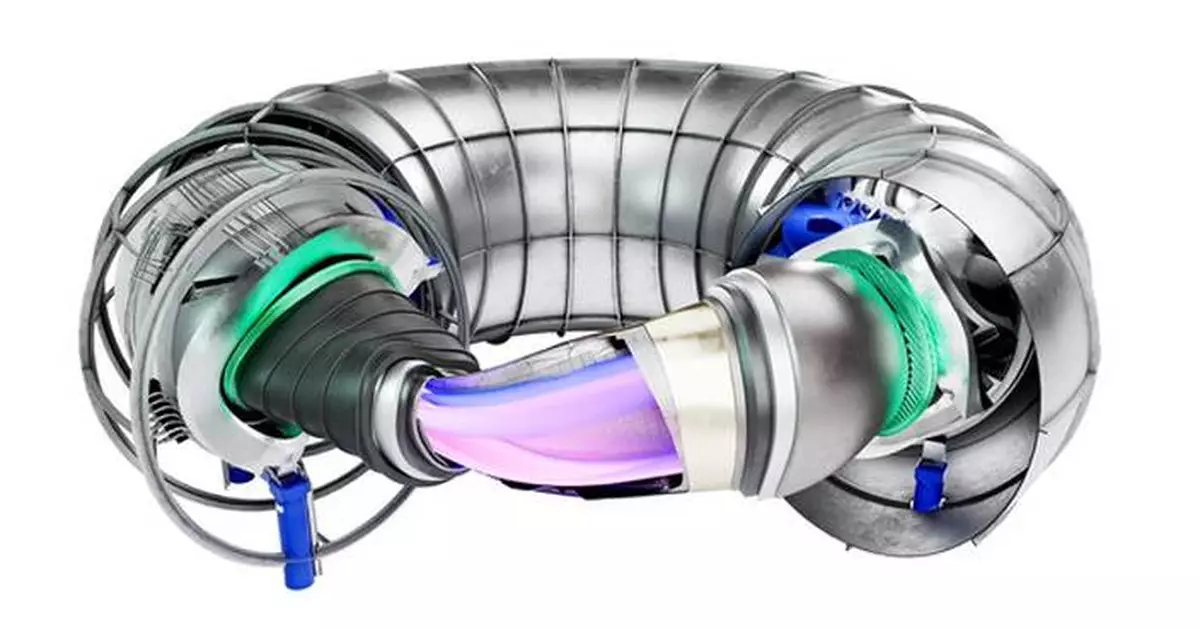

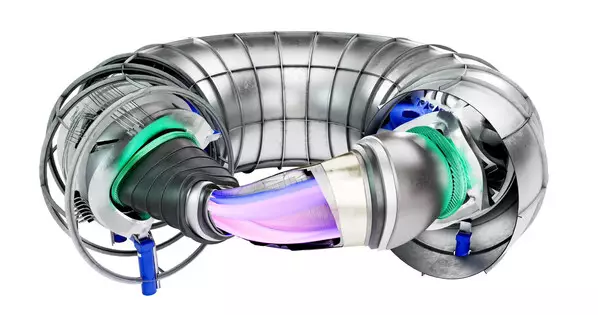

Proxima Fusion’s first-of-a-kind power plant Stellaris will use high temperature superconductor magnets to confine the burning plasma

Stellarators are fusion machines which contain hot, ionized matter (plasma) within a magnetic field of remarkable strength and sophisticated geometry. Significant progress including the highest plasma triple product sustained for tens of seconds was attained recently with the W7-X stellarator, which is built and operated by the Max Planck Institute of Plasma Physics (IPP) in Germany. Proxima Fusion, originally spun out from the IPP, is building on the record-breaking expertise of W7-X, combining it with advances in stellarator optimization, computational design and state-of-the-art HTS magnet technology.

After completing delivering its demo magnet in 2027, Proxima will focus on the delivery of Alpha in 2031, Proxima's net-energy demo stellarator, followed by the first-of-a-kind commercial fusion power plant Stellaris in the 2030s. Timely supply of high-quality HTS tape is essential to keep fusion on fast track. While it takes thousands of kilometers of superconducting tape to build a typical energy-positive fusion prototype, scaling up the fusion industry to commercial power will require millions of kilometers.

Since 2020, Faraday Factory has ramped up production by 10 times. The new HTS tape delivery contract is an important milestone, further strengthening the HTS supply chain for the nascent but transformative fusion industry.

The contract is an important milestone strengthening HTS supply chain of the fusion industry

TOKYO, June 20, 2025 /PRNewswire/ -- Proxima Fusion and Faraday Factory Japan have signed a contract for the supply of high temperature superconducting (HTS) tape. This delivery will help the leading European stellarator developer Proxima Fusion to achieve its next milestone – a superconducting demo magnet.

Proxima Fusion’s first-of-a-kind power plant Stellaris will use high temperature superconductor magnets to confine the burning plasma

Proxima Fusion’s first-of-a-kind power plant Stellaris will use high temperature superconductor magnets to confine the burning plasma

Stellarators are fusion machines which contain hot, ionized matter (plasma) within a magnetic field of remarkable strength and sophisticated geometry. Significant progress including the highest plasma triple product sustained for tens of seconds was attained recently with the W7-X stellarator, which is built and operated by the Max Planck Institute of Plasma Physics (IPP) in Germany. Proxima Fusion, originally spun out from the IPP, is building on the record-breaking expertise of W7-X, combining it with advances in stellarator optimization, computational design and state-of-the-art HTS magnet technology.

After completing delivering its demo magnet in 2027, Proxima will focus on the delivery of Alpha in 2031, Proxima's net-energy demo stellarator, followed by the first-of-a-kind commercial fusion power plant Stellaris in the 2030s. Timely supply of high-quality HTS tape is essential to keep fusion on fast track. While it takes thousands of kilometers of superconducting tape to build a typical energy-positive fusion prototype, scaling up the fusion industry to commercial power will require millions of kilometers.

Since 2020, Faraday Factory has ramped up production by 10 times. The new HTS tape delivery contract is an important milestone, further strengthening the HTS supply chain for the nascent but transformative fusion industry.

Proxima Fusion’s first-of-a-kind power plant Stellaris will use high temperature superconductor magnets to confine the burning plasma

** The press release content is from PR Newswire. Bastille Post is not involved in its creation. **

Faraday Factory Japan signed an agreement to deliver superconductor tape for the demo stellarator magnet of Proxima Fusion

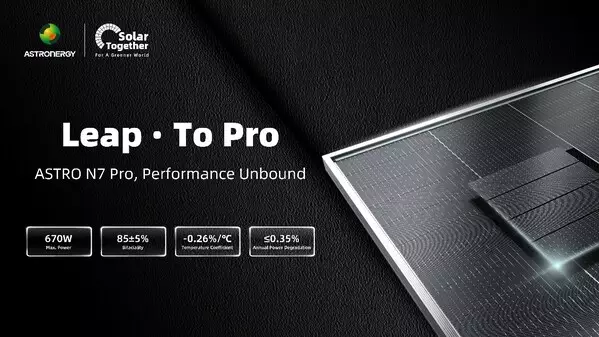

HANGZHOU, China, Jan. 8, 2026 /PRNewswire/ -- On January 7th, Astronergy officially launched ASTRO N7 Pro, the company's next-generation PV modules designed to set new benchmarks in power output, efficiency, and long-term system value. Featuring a power output of up to 670W and a maximum efficiency of 24.8%, ASTRO N7 Pro addresses the evolving demands of utility-scale and C&I distributed solar projects globally.

ASTRO N7 Pro is powered by Astronergy's upgraded TOPCon 5.0+ solar cell technology, integrating industry-leading technologies such as ASP, PF, SNOP. A key upgrade is the adoption of quarter-cut design: quarter-cut cell tech reduces internal current of cells, lowering power loss. Meanwhile, quarter-cut cell layout design effectively reduces the peak hot spot temperature and power loss, improving module reliability and system safety.

In practical operating environments, ASTRO N7 Pro demonstrates strong resilience under partial shading conditions. Its unique circuit design effectively reduces shading impact, enabling up to 20% more power output than half-cut-cell modules when shading occurs.

These modules also deliver reliable performance in low-irradiance and high-temperature conditions. Improved Rsh and fewer current leakage paths enable ASTRO N7 Pro to achieve 6.05% increase in single-watt power gain compared with BC products. This ensures stable energy production during early mornings, late afternoons and cloudy weather. Supported by a temperature coefficient of -0.26%/°C, ASTRO N7 Pro can maintain consistent power generation in regions with high temperatures.

With bifaciality reaching up to 85±5%, ASTRO N7 Pro earns 1–3% additional bifacial power gains over BC products. Its reliability is further reinforced through the quarter-cut cell layout, 20BB design, and a low-temperature & low-stress manufacturing process without flux, which together lead to a more uniform stress distribution, reduced hidden crack risks, and durable long-term performance.

Designed for higher returns across the project lifecycle, ASTRO N7 Pro comes with a 30-year linear power warranty and a 15-year product warranty. Compared with same-size BC modules, there's a 1.2% increase in both first-year power generation and 30-year cumulative power generation, and LCOE is cut by 1.2%.

ASTRO N7 Pro is more than just a new product series, but Astronergy's continued focus on customer needs across diverse application scenarios. With the launch of ASTRO N7 Pro, Astronergy keeps powering a sustainable future through innovation, reliability and greater profits.

** The press release content is from PR Newswire. Bastille Post is not involved in its creation. **

Astronergy Launches ASTRO N7 Pro to Unleash Pro Performance