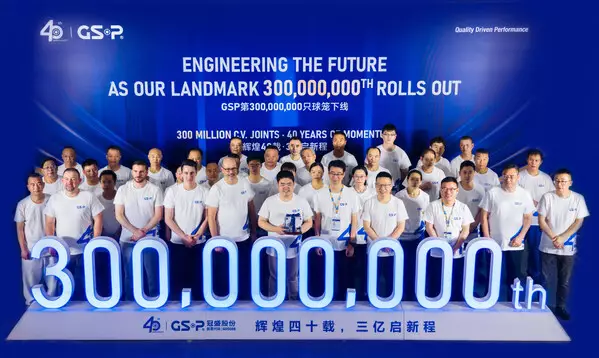

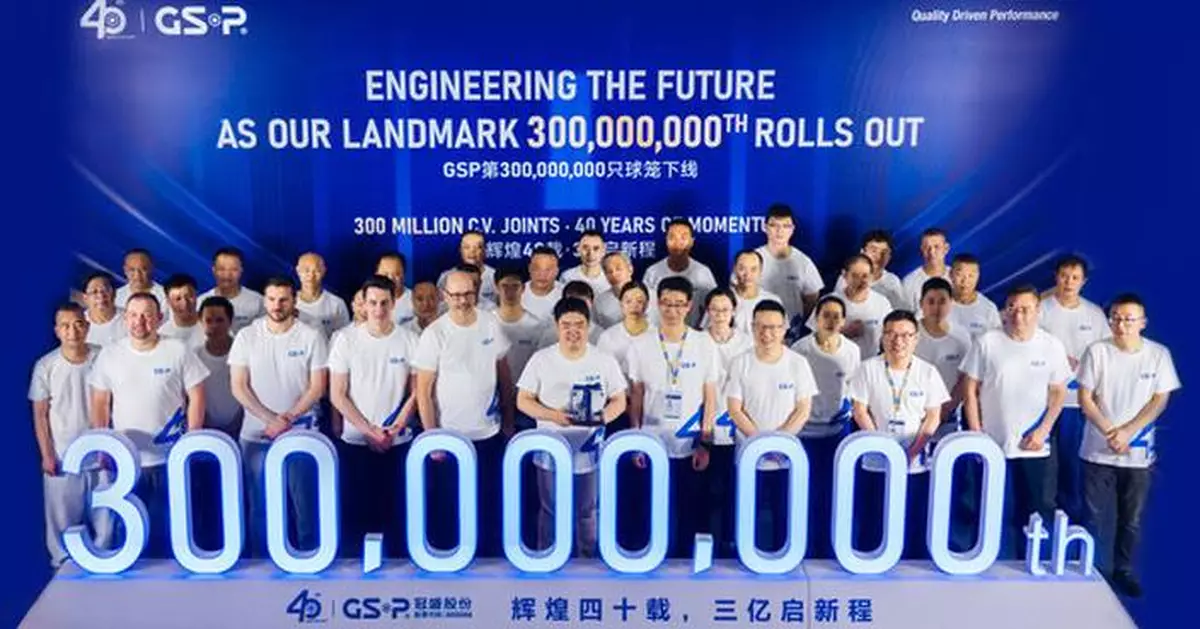

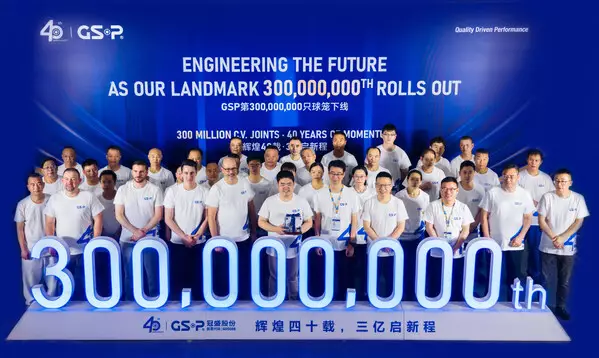

WENZHOU, China, July 11, 2025 /PRNewswire/ -- GSP has marked the arrival of it's 40th anniversay with the rollout of its 300-millionth CV joint.

The milestone was marked with an official ceremony at its Wenzhou, China manufacturing facility.

This sets a new global benchmark for single-category automotive part production, says the company.

Executives and product leaders from Germany, the United States, Brazil, and other regions gathered to witness the occasion, which reflects GSP's four-decade journey from a single-product manufacturer to a global industry leader.

"The 300-millionth CV joint represents not just a number — it's a testament to the dedication of GSP employees and the trust placed in us by customers worldwide," said Richard Zhou, CEO of GSP Group, reflecting on the company's growth.

Daolun Zheng, Director of the Driveshaft Division and one of GSP's earliest employees, shared stories from the company's early days:

"When we launched our first CV joint, we personally visited over 20 countries, carrying samples and resolving 128 complex technical parameters over three years."

David Michaux, Director of Global Product Management explained how GSP got here: "Because GSP listens to GSP customers. It's 300 million times that our parts helped vehicles move, families travel safely, and customers trust our brand."

Today, GSP produces over 2.5 million CV joints monthly, with 49 patents, a 100% inspection rate, and several national certifications — including National Key New Products (2007, 2008, 2012) and National Torch Program Projects (2005, 2011). The company has also played a leading role in drafting four national industry standards, including JB/T 10189-2023 for constant velocity joints.

GSP's growth strategy evolved from a single-product focus to a full undercar parts ecosystem, including:

- Drive Shafts

- Hub Assemblies

- Shock Absorbers

- Rubber-to-Metal Components

- Steering & Suspension Parts

Through its AM + OE hybrid development model, GSP offers a one-stop solution with multi-category engineering integration and full-vehicle coverage.

The company's global operations — available in 11 languages — are powered by a dual commitment to Global Technical Excellence and Localized Precision Execution, enabling consistent quality and agile service across 120 countries.

With over 95% application coverage of mainstream vehicle models, GSP delivers OE-level quality and end-to-end service, including design, smart manufacturing, and after-sales support.

This precision-engineered component not only represents unmatched production capability, but also GSP's vision to fuel customer growth through innovation, reliability, and unmatched service.

About GSP Automotive Group:

GSP Automotive Group is a global leader in the design, manufacturing, and distribution of automotive driveline components, including CV axles, hub assemblies, loaded struts, and suspension solutions. With over 40 years of innovation and a commitment to quality-driven performance, GSP serves OEM and aftermarket customers across more than 120 countries. GSP combines advanced engineering, IATF-certified production, and a global supply chain to deliver trusted undercar solutions worldwide.

** The press release content is from PR Newswire. Bastille Post is not involved in its creation. **

GSP MARKS 40TH YEAR WITH 300 MILLIONTH CV JOINT

HONG KONG, Dec. 23, 2025 /PRNewswire/ -- The Education University of Hong Kong (EdUHK) has received a donation of HK$2.95 million from the Sprinkles (HK) Charity Foundation ("Sprinkles") to develop the "Harmony between Humanity and Nature Sustainable Education" project. Through curriculum development, teacher training, and community engagement, the project aims to enhance student and public awareness and action regarding environmental protection, sustainable development, and green finance. It specifically addresses the current lack of awareness of green issues among youth and helps establish deeper cultural resonance by exploring the application of traditional Chinese wisdom in modern environmental education.

The cheque presentation ceremony was held at EdUHK on December 19, 2025. Dr. Ma Jun, Chairman of Sprinkles, presented the donation on behalf of the Foundation. It was received by EdUHK representatives: President Professor John Lee Chi-Kin; Professor YUNG, Kin Lam Ken, Associate Vice President (Knowledge Transfer and Sustainability); Associate Vice President (Knowledge Transfer and Development); and Dr. Lai Chi-shing, Senior Lecturer of the Department of Chinese Language Studies. Professor Karen Cheung, President of the UNESCO Hong Kong Association and Dean of the Hong Kong Institute of Education for Sustainable Development, also attended to witness the event.

The research will pioneeringly integrate "Green Finance Education," a key focus of the Foundation, with traditional ecological philosophy. It aims to construct a "Harmony between Humanity and Nature" environmental education model, providing a new paradigm for global sustainable development education that combines cultural depth with an empirical foundation, further realizing the Foundation's vision of "benefiting mankind through ecological protection."

EdUHK President John Lee expressed his heartfelt gratitude for Sprinkles' support. He noted, "Sustainable education is not merely the transmission of knowledge, but the shaping of values and behaviors. We hope that through education, we can cultivate future generations to live more responsibly and work together to build a more resilient society."

President Lee praised Sprinkles for engaging in "a cause with vision, action, and warmth," and looked forward to further deepening the integration of environmental concepts and educational practices with the Foundation's support, jointly creating a greener and more inclusive future.

Dr. Ma Jun stated that he is delighted to establish a partnership with EdUHK. He believes that leveraging EdUHK's professional strengths and rich experience in the education sector will inject continuous momentum into the sustainable development of society.

Sprinkles has always been committed to environmental education and the promotion of green finance. In addition to organizing the "Children's Environmental Essay and Painting Competition," it has produced environmental education animations such as "Raine's Green Realm Rescue" (tentatively titled). Supporting EdUHK's "Harmony between Humanity and Nature Sustainable Education" research continues the Foundation's emphasis on education. Drawing on past experience in producing environmental animations, the project will attempt to combine AI technology to design teaching materials and curricula, hoping to cultivate students' ecological awareness in a vivid manner and further enhance the standard and dissemination capabilities of green finance education. Furthermore, this research will explore the practical application of Chinese ecological concepts across different geopolitical and cultural backgrounds, aligning with Sprinkles' vision of promoting cross-regional exchange to spread green concepts further.

About Sprinkles (HK) Charity Foundation

The Sprinkles (HK) Charity Foundation is a charitable foundation initiated in Hong Kong by Dr. Ma Jun, Chairman and President of the Hong Kong Green Finance Association, along with a group of like-minded individuals passionate about public welfare. It is dedicated to supporting and promoting charitable causes such as research, concept promotion, public education, and international cooperation in areas including green development, environmental protection, climate change response, and biodiversity conservation.

Since the Spring Sunrise" Children's Environmental Writing and Drawing Competition in 2022 received an enthusiastic response, Sprinkles, together with the Compassion Award - Xu Xiaohui Memorial Fund, has successfully held three editions. These have gained widespread social recognition, receiving over 2,700 excellent entries from Hong Kong students.

Since 2023, serving as the Hong Kong Secretariat for the Capacity-building Alliance of Sustainable Investment (CASI), which has over 70 member institutions globally, Sprinkles has helped organize a series of green finance capacity-building activities in Latin America, Hong Kong, Huzhou, the Middle East, Central/West Asia, and Africa, with over 5,000 trainees and beneficiaries.

Sprinkles continues to invest more resources to make environmental knowledge easily understandable to the public through lively and interesting methods, sparking concern for environmental issues and cultivating a group of young environmental guardians holding the "Harmony between Humanity and Nature" philosophy. The Foundation has also initiated an AI environmental education animation development project, aiming to enable children and adolescents to recognize, understand, and learn how to protect the environment, educating and inspiring the next generation to become active participants and future leaders in addressing climate change and environmental protection.

Sprinkles (HK) Charity Foundation is a charitable institution exempt from tax under Section 88 of the Inland Revenue Ordinance of the Hong Kong Government.

Website: https://www.sprinkles.org.hk

** The press release content is from PR Newswire. Bastille Post is not involved in its creation. **

Sprinkles (HK) Charity Foundation Donates to The Education University of Hong Kong to Promote "Harmony between Humanity and Nature Sustainable Education" Project