TOKYO--(BUSINESS WIRE)--Jul 17, 2025--

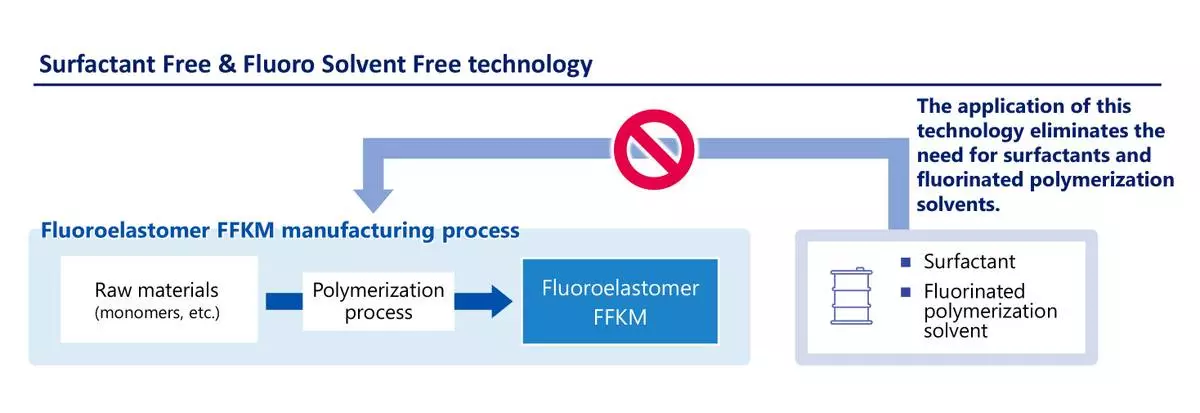

AGC (AGC Inc., Headquarters: Tokyo; President: Yoshinori Hirai)(TOKYO:5201), a world-leading manufacturer of glass, chemicals and other high-tech materials, proudly announces the launch of surfactant and fluorinated polymerization solvent free grades in its fluoroelastomer “AFLAS™ FFKM” series; the SF grades (the “Products”). The newly developed Products are manufactured entirely without the use of any surfactants *1 or fluorinated polymerization solvents *2. The Products offer high performance equivalent to that of conventional products, while meeting the growing market demand for fluoroelastomers that do not use surfactants or fluorinated polymerization solvents during the manufacturing process. This has been achieved through AGC’s innovative, proprietary polymer manufacturing technology (Surfactant-Free & Fluoro Solvent-Free Technology, hereafter the “Technology”). Initially, this Technology will be applied to the high-temperature-resistant type of FFKM fluoroelastomers and new grades will be added to the “AFLAS™ FFKM” series for semiconductor manufacturing equipment. Commercial availability of this new grade begins this month. We are planning to extend the Technology to other types of FFKM fluoroelastomers and will progressively introduce those new types of Products as part of “AFLAS™ FFKM” series.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20250717721155/en/

The “AFLAS™ FFKM” series is an industrial elastomer that offers one of the highest levels of resistance to chemicals, heat, and plasma among fluoroelastomers. Its outstanding properties make it exceptionally durable even in harsh environments such as semiconductor manufacturing, oil drilling, and healthcare. In particular, “AFLAS™ FFKM” is recognized as an essential material in the etching process, one of the key steps in semiconductor manufacturing, due to its exceptional plasma resistance. Its resistance to degradation makes it an ideal sealing material for etching equipment, where it contributes to significantly extended maintenance intervals and enhanced operating safety.

Previously, surfactants and fluorinated polymerization solvents were considered essential for manufacturing high performance fluoroelastomers, FFKM, due to their roles in enhancing the reactivity of fluorinated monomers and manufacturing efficiency. In recent years, however, customers’ demand for products that do not use these substances during the manufacturing process have grown rapidly, particularly in the semiconductor industry. While various approaches without using surfactants or fluorinated polymerization solvents have been explored, achieving the high-performance requirements of FFKM was a significant challenge.

To meet this market demand, AGC has successfully overcome this long-standing technical challenge and succeeded in mass-production of the Products by applying the new Technology, which does not require the use of any type of surfactants or fluorinated polymerization solvents, which has been developed by refining our unique polymerization technology cultivated over many years. Accordingly, AGC is now proud to introduce the Products as new addition to its AFLAS™ FFKM series.

Under its corporate philosophy of “Look Beyond”, the AGC Group is committed to supporting the lives of people around the world through its unique materials and solutions. Going forward, we will continue to contribute to the realization of a safe, secure, and sustainable society through our high-performance, high-quality materials.

REFERENCE

Website of AFLAS™ FFKM series

AGC’s innovative Surfactant-Free & Fluoro Solvent-Free polymer manufacturing technology

AFLAS(TM) FFKM Series Logo