|

- Recycled styrene monomer produced via depolymerisation now delivered at scale

- Enables high-quality styrenics, including for food-grade and medical applications

- Adds chemically recycled material to our portfolio alongside mechanically recycled and bio-attributed products

FRANKFURT, Germany, Sept. 25, 2025 /PRNewswire/ -- The first truckloads of recycled styrene monomer (SM) have arrived at INEOS Styrolution's Antwerp site. The material was supplied by Indaver from its new depolymerisation plant, the first facility in Europe dedicated to polystyrene recycling, inaugurated on 25th September 2025. Also located in Antwerp, this local set-up keeps the supply chain short and sustainable.

This is the first commercial-scale delivery of recycled SM in Europe. It enables the production of high-quality polystyrene and other styrenics, including for food-grade, transparent, and medical applications.

This recycled feedstock adds to INEOS Styrolution's sustainable styrenics portfolio, which already comprises mechanically recycled and bio-attributed grades, and demonstrates the company's ability to deploy multiple recycling technologies for different waste streams.

"We are pleased that we can now offer styrenics from depolymerisation at market scale", remarks Rob Buntinx, President EMEA, INEOS Styrolution. "This gives our customers more sustainable options to lower their environmental footprint without compromising product quality or performance."

"With Plastics2Chemicals (P2C), Indaver is pioneering in the circular economy and advanced chemical recycling. By converting hard-to-recycle plastics into virgin-quality feedstock such as styrene, we are closing the loop and offering a sustainable alternative to fossil resources", states Erik Moerman, Sales and Development Director P2C. "Our in-house developed technology, combined with strategic partnerships and continuous innovation, enables us to deliver high-purity materials for demanding applications like food packaging − proving that circularity and performance can go hand in hand."

This milestone highlights what sets polystyrene apart: it can be broken back down to its original monomer and rebuilt for high-value use. Depolymerisation is also more energy-efficient than other advanced recycling methods such as pyrolysis. It keeps the material in circulation, turning waste back into a valuable resource instead of landfill or litter.

Further information:

Depolymerisation is a chemical recycling process that breaks polystyrene down into its original building block styrene monomer, in contrast to mechanical recycling where plastic waste is physically processed back into pellets, without changing the basic chemical structure of the material. As the material is returned to the molecular level during depolymerisation, it enables the production of new styrenics with the same quality and properties as fossil-based products, including compliance with strict food-contact standards. Compared to conventional fossil-based production, depolymerisation avoids multiple resource-intensive steps, resulting in lower resource use and significantly reduced greenhouse gas emissions.

About INEOS Styrolution

INEOS Styrolution is the number one producer of high-performance styrenics, offering a broad portfolio that comprises styrene monomer, polystyrene, ABS, and advanced styrenics. The company delivers customised solutions for customers across automotive, healthcare, electronics, household, construction, packaging, toys, sports and leisure sectors. With more than 90 years of innovation in material science and 16 production sites worldwide, INEOS Styrolution combines global reach with local expertise to meet the evolving needs of its customers. This includes bringing safe, sustainable, and high-performing products to market and supporting their efforts toward meeting their sustainability targets.

INEOS Styrolution is fully owned by INEOS Group.

For further information, please visit: www.ineos.com/styrolution

- Recycled styrene monomer produced via depolymerisation now delivered at scale

- Enables high-quality styrenics, including for food-grade and medical applications

- Adds chemically recycled material to our portfolio alongside mechanically recycled and bio-attributed products

FRANKFURT, Germany, Sept. 25, 2025 /PRNewswire/ -- The first truckloads of recycled styrene monomer (SM) have arrived at INEOS Styrolution's Antwerp site. The material was supplied by Indaver from its new depolymerisation plant, the first facility in Europe dedicated to polystyrene recycling, inaugurated on 25th September 2025. Also located in Antwerp, this local set-up keeps the supply chain short and sustainable.

This is the first commercial-scale delivery of recycled SM in Europe. It enables the production of high-quality polystyrene and other styrenics, including for food-grade, transparent, and medical applications.

This recycled feedstock adds to INEOS Styrolution's sustainable styrenics portfolio, which already comprises mechanically recycled and bio-attributed grades, and demonstrates the company's ability to deploy multiple recycling technologies for different waste streams.

"We are pleased that we can now offer styrenics from depolymerisation at market scale", remarks Rob Buntinx, President EMEA, INEOS Styrolution. "This gives our customers more sustainable options to lower their environmental footprint without compromising product quality or performance."

"With Plastics2Chemicals (P2C), Indaver is pioneering in the circular economy and advanced chemical recycling. By converting hard-to-recycle plastics into virgin-quality feedstock such as styrene, we are closing the loop and offering a sustainable alternative to fossil resources", states Erik Moerman, Sales and Development Director P2C. "Our in-house developed technology, combined with strategic partnerships and continuous innovation, enables us to deliver high-purity materials for demanding applications like food packaging − proving that circularity and performance can go hand in hand."

This milestone highlights what sets polystyrene apart: it can be broken back down to its original monomer and rebuilt for high-value use. Depolymerisation is also more energy-efficient than other advanced recycling methods such as pyrolysis. It keeps the material in circulation, turning waste back into a valuable resource instead of landfill or litter.

Further information:

Depolymerisation is a chemical recycling process that breaks polystyrene down into its original building block styrene monomer, in contrast to mechanical recycling where plastic waste is physically processed back into pellets, without changing the basic chemical structure of the material. As the material is returned to the molecular level during depolymerisation, it enables the production of new styrenics with the same quality and properties as fossil-based products, including compliance with strict food-contact standards. Compared to conventional fossil-based production, depolymerisation avoids multiple resource-intensive steps, resulting in lower resource use and significantly reduced greenhouse gas emissions.

About INEOS Styrolution

INEOS Styrolution is the number one producer of high-performance styrenics, offering a broad portfolio that comprises styrene monomer, polystyrene, ABS, and advanced styrenics. The company delivers customised solutions for customers across automotive, healthcare, electronics, household, construction, packaging, toys, sports and leisure sectors. With more than 90 years of innovation in material science and 16 production sites worldwide, INEOS Styrolution combines global reach with local expertise to meet the evolving needs of its customers. This includes bringing safe, sustainable, and high-performing products to market and supporting their efforts toward meeting their sustainability targets.

INEOS Styrolution is fully owned by INEOS Group.

For further information, please visit: www.ineos.com/styrolution

** The press release content is from PR Newswire. Bastille Post is not involved in its creation. **

INEOS Styrolution marks milestone with first commercial delivery of recycled styrene monomer from Indaver

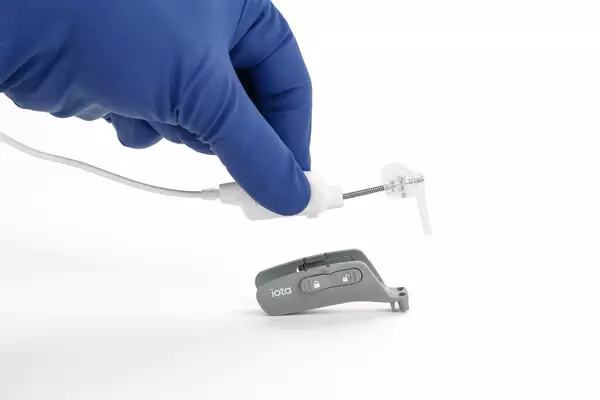

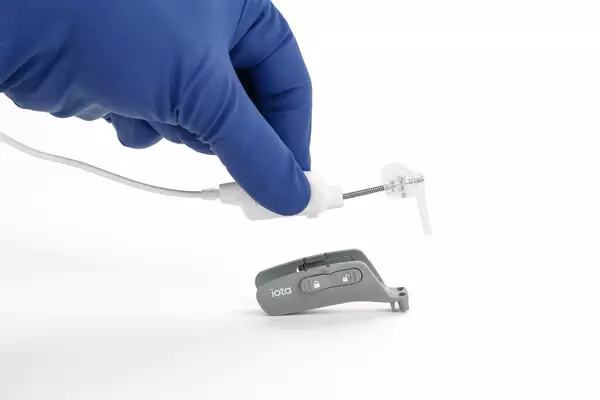

ST. PAUL, Minn., Jan. 14, 2026 /PRNewswire/ -- iotaMotion, Inc., creator of iotaSOFT®, the first and only FDA cleared robotic-assisted cochlear implant insertion system, today announced U.S. Food and Drug Administration (FDA) 510(k) clearance for expanded pediatric use of its iotaSOFT® Insertion System. The system is now cleared for use in patients four years of age and older, extending access to robotic-assisted cochlear implantation for school-aged children.

"Receiving FDA clearance for expanded pediatric use marks a significant milestone for iotaMotion and for families navigating cochlear implant decisions," said Mike Lobinsky, CEO of iotaMotion. "By standardizing one of the most delicate steps in cochlear implant surgery, iotaSOFT helps reduce variability which could provide parents greater confidence as they consider cochlear implantation for their children."

The iotaSOFT Insertion System enables precise and controlled electrode array insertion during one of the most delicate steps of cochlear implant surgery. By standardizing this critical step, iotaSOFT is designed to help preserve delicate cochlear structures, a consideration that is often central to decision-making.

As part of this milestone, Cincinnati Children's Hospital, a nationally ranked pediatric medical center, and U.S. News & World Report Honor Roll member for 2025–2026, has become the first dedicated pediatric center to adopt the iotaSOFT Insertion System. Cincinnati Children's joins over 35 leading cochlear implant centers across the United States, including nearly half of U.S. neurotology fellowship training programs, that have adopted this innovative technology.

"At Cincinnati Children's, our focus is delivering the highest standard of care while thoughtfully integrating innovations that benefit our patients," said Dr. Daniel Choo, chief clinical growth officer and professor of otolaryngology–head and neck surgery. "Robotic-assisted cochlear implantation represents a meaningful advancement in our cochlear implant program."

Globally, fewer than 5% of eligible cochlear implant candidates receive an implant, despite more than 430 million people worldwide experiencing disabling hearing loss, according to the World Health Organization. In pediatric patients, early access to sound is critical for speech, language and educational development, yet concerns around hearing preservation and surgical variability can delay intervention.

A 2025 clinical cohort study published in The Laryngoscope (Khan et al.) found that 85% of patients in the robotic-assisted insertion group maintained hearing preservation at one year, compared with 71% in the manual insertion group, according to its authors.

"Robotic assistance in cochlear implantation is about precision and consistency," said Marlan Hansen, MD, co-founder and chief medical officer of iotaMotion. "With the expanded pediatric indication for iotaSOFT, supported by growing clinical evidence, families can have greater confidence that controlled, standardized insertion is designed to protect the cochlea and preserve its structure and function. This is especially important for children who may benefit from emerging therapeutic advances, including gene-based and regenerative hearing technologies, which will likely depend on atraumatic, cochlear implant array placement early in life."

About iotaMotion

iotaMotion, Inc. is a medical technology company based in St. Paul, Minnesota, dedicated to advancing cochlear implant surgery beyond human capability through robotic-assisted solutions. Its flagship technology, the iotaSOFT® Insertion System, is designed to preserve delicate intracochlear structures through slow and consistent electrode array insertion. The system is commercially available in the United States and under clinical investigation in other global markets.

For more information, visit http://www.iotamotion.com/ and follow us on LinkedIn, X, Facebook, YouTube.

Sources:

Claussen AD, et al. Comparative Analysis of Robotics-Assisted and Manual Insertions of Cochlear Implant Electrode Arrays. Otol Neurotol, 2022.

Khan AM, et al. Robotic-Assisted Electrode Array Insertion Improves Rates of Hearing Preservation. The Laryngoscope, 2025.

Data on file

Media Contact:

Sara Ashburn-Reed

Sashburn-reed@iotamotion.com

** The press release content is from PR Newswire. Bastille Post is not involved in its creation. **

iotaMotion Receives FDA Clearance for Expanded Pediatric Use of iotaSOFT® Robotic-Assisted Cochlear Implant Insertion System

iotaMotion Receives FDA Clearance for Expanded Pediatric Use of iotaSOFT® Robotic-Assisted Cochlear Implant Insertion System

iotaMotion Receives FDA Clearance for Expanded Pediatric Use of iotaSOFT® Robotic-Assisted Cochlear Implant Insertion System