CALGARY, Canada--(BUSINESS WIRE)--Jan 13, 2026--

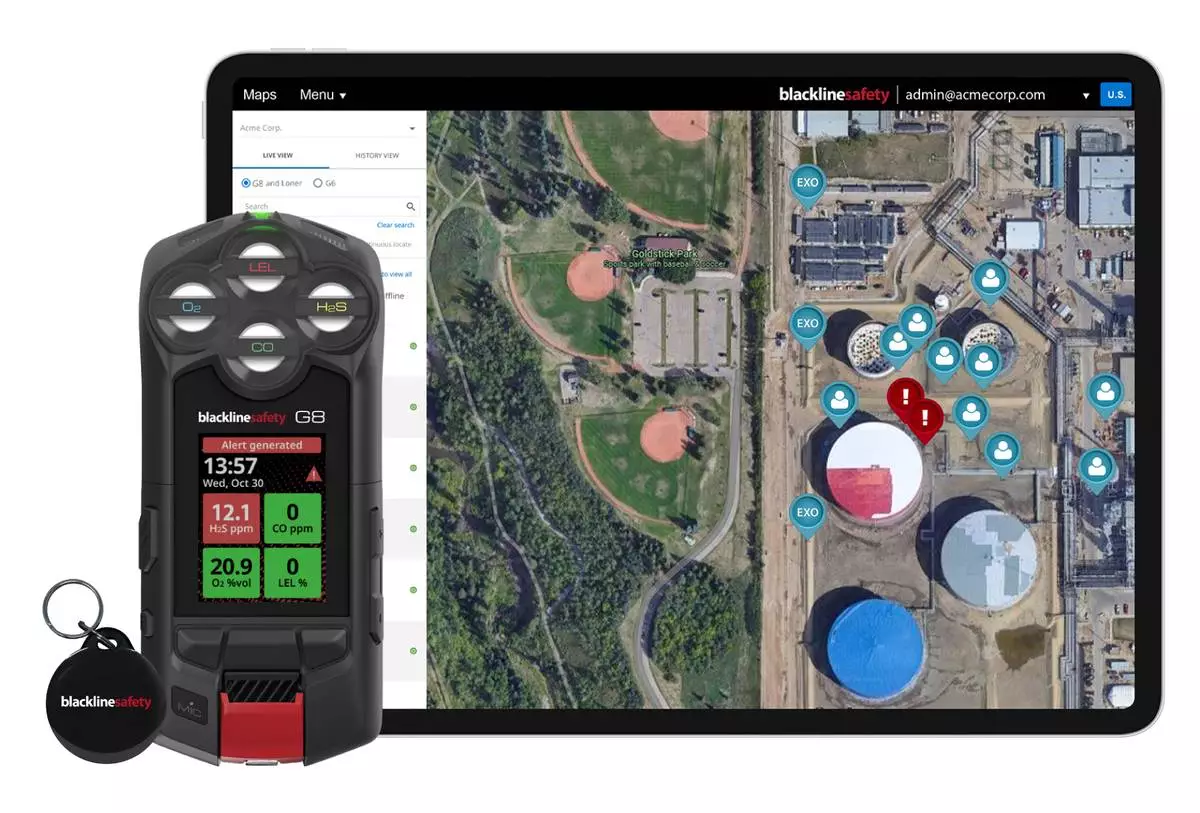

Blackline Safety Corp. (TSX: BLN), a global leader in connected safety technology, today announced G8, the next evolution of worksite safety and the most connected wearable the company has ever built. Designed from the ground up as a true platform, G8 combines advanced gas detection, lone worker protection, and radio-quality communication in one rugged device that connects workers to each other, to their safety teams, and to the broader digital worksite—with real-time data streamed to the cloud to keep safety and operations leaders informed.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20260113439071/en/

“G8 gives workers access to the tools and information they need to confidently get the job done and get home safe,” said Cody Slater, CEO and Chair, Blackline Safety. “By unifying gas detection, real-time monitoring, and communication in one connected device, we’re delivering more than incremental improvement. We’re giving every worker a direct line to the people, data, systems and support they need to make faster, safer decisions.”

G8 builds on the proven foundation of Blackline’s G7 line, while introducing breakthrough capabilities that set a new standard for connected safety and productivity.

A Connected Gas Detector That Does More

At its core, G8 is a fully featured, connected gas detector with a rugged, IP-67 rating that’s built to meet the most demanding industrial environments.

But G8 also goes further, consolidating several critical tools into one intrinsically safe device, so workers no longer need to carry and manage multiple devices. Plus, real-time cloud connectivity so teams get the field data they need to respond faster and keep operations running smoothly. With G8, organizations get:

Safety and situational awareness:

3 ways to communicate (in emergencies or for everyday productivity) with enhanced speaker and mic technology:

Visibility and usability:

Real-Time Data That Drives Safer, More Productive Work

Every G8 streams live data to Blackline’s data and analytics platform—Blackline Live—via the cloud. This gives safety leaders real-time visibility into worker status, gas readings, and site conditions, and it gives operations teams actionable insights to prevent incidents, reduce delays, and keep projects moving.

A Platform Built for Today—and What Comes Next

Unlike traditional gas detectors, G8 functions as a connected platform that’s built to be able to integrate with the rest of the digital worksite. It’s future-ready to plug into other digital platforms that organizations use today, from human resource management systems (HRMS) to field service management tools to hot-permitting applications and more, helping eliminate manual workflows and remove barriers to getting work done.

And because G8 receives automatic firmware updates, it will continue to evolve with new capabilities, expanded integrations, and emerging technologies like AI-driven insights.

“We’re talking about a platform built to grow with you,” said Phil Benson, VP, Product, Blackline Safety. “As worksites become more connected, automated and data-driven, G8 has the flexibility to meet tomorrow’s needs, not just today’s. It lays the foundation for future capabilities like AI integrations, expanded calling features, and predictive analytics that will continue to raise the bar for connected work for years to come.”

G8 is protected by more than a dozen patents with additional patents pending.

Blackline is taking orders today, with first shipments expected in February 2026. To learn more about G8 and some upcoming events, including a LinkedIn Live on February 2 and a product webinar on February 25, visit www.blacklinesafety.com/G8.

About Blackline Safety: Blackline Safety is a technology leader driving innovation in the industrial workforce through IoT (Internet of Things). With connected safety devices and predictive analytics, Blackline enables companies to drive towards zero safety incidents and improved operational performance. Blackline provides wearable devices, personal and area gas monitoring, cloud-connected software and data analytics to meet demanding safety challenges and enhance overall productivity for organizations with customers in more than 75 countries. Armed with cellular and satellite connectivity, Blackline provides a lifeline to tens of thousands of people, having reported over 300 billion data-points and initiated over eight million emergency alerts. For more information, visit BlacklineSafety.com and connect with us on Facebook, X (formerly Twitter), LinkedIn and Instagram.

G8 features enhanced audio quality and an optional remote speaker microphone for clear, reliable communication in extremely loud environments.

G8 feeds live field data to Blackline Live software for a real-time view of workers and worksites, and all-new TagAssignTM capabilities allow for one-tap device assignment.

G8 has a 64-color backlit display that's nearly twice the size of its predecessor G7's display for clearer visibility in any work environment.