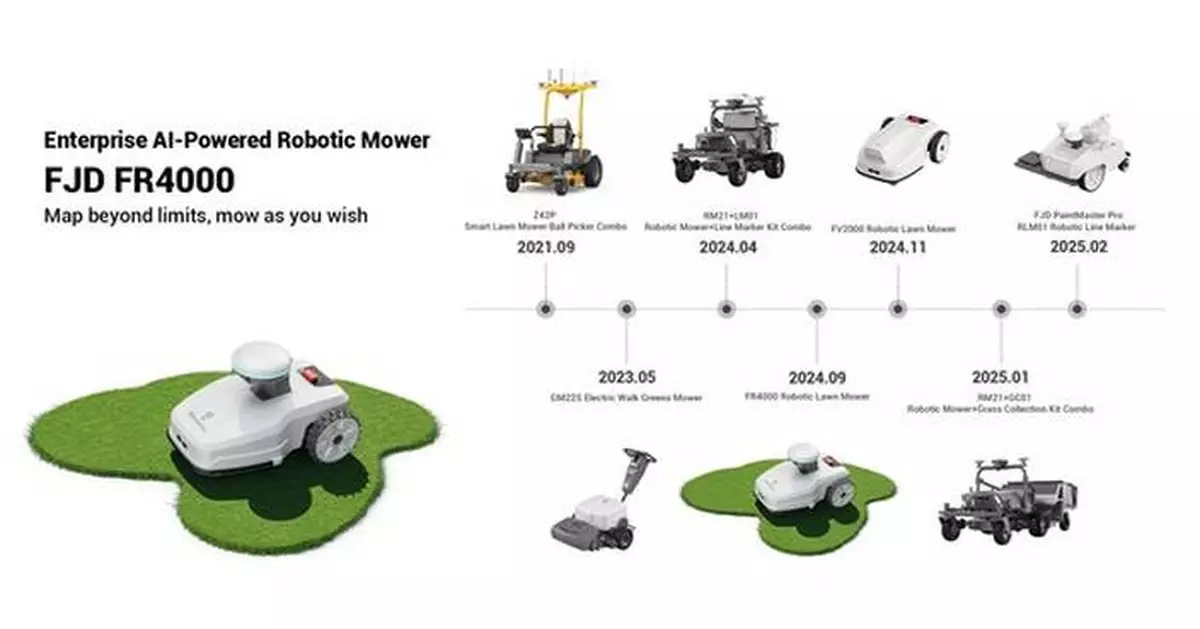

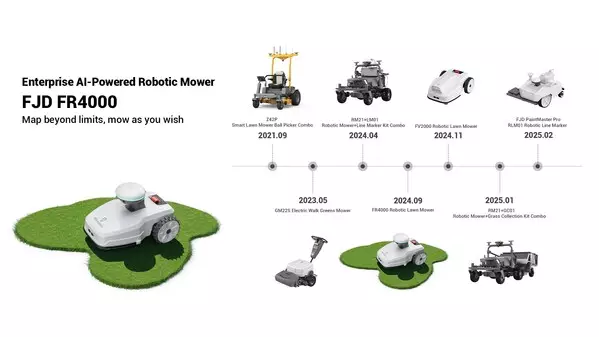

SHENZHEN, China, March 25, 2025 /PRNewswire/ -- FJDynamics, the global innovator in smart lawn care and maintenance solutions, announced the expansion of its highly anticipated robotic lawn care portfolio. The company's latest AI-powered mowing robots are setting new industry benchmarks for precision, efficiency, and sustainable landscape management across residential, commercial, and sports field applications.

FJD FR4000: Commercial-Grade Precision

Engineered for large-scale operations, the FR4000 combines industrial-grade RTK positioning with advanced vision to achieve centimeter-level accuracy even on slopes up to 33° (65%). By mapping turf areas with intelligent algorithms, the FR4000 creates optimal cutting zones without needing troublesome perimeter wiring. Key advantages:

- Large-area efficiency: Cover up to 10,000㎡ (2.47 acres) within 3 days.

- Drop & run: Allow instant deployment and start mowing tasks without the need for the charging station.

- Fleet management: Enable coordinated operation of multiple units across complex landscapes.

- Autonomy: Operate autonomously by managing mowing, recharging, safety monitoring, and cutting height adjustment with adaptive responsiveness.

FJD FV2000: Smart Residential Mowing Assistant

For homeowners, FJDynamics also offers the FV2000 model, a robotic mower that also leverages the company's time-tested RTK and vision fusion navigation technology with its fully automated, wire-free design. The key features:

- Kid/pet-safe navigation: Create optimal mowing paths based on AI while avoiding objects along the paths.

- Multi-zone management: Just drop it on any zone of the yards, and it can start mowing to complete multi-zone tasks with ease.

- Large mowing area: Mow lawns up to 6,000㎡ (1.5 acres) in just 3 days.

In addition to robotic mowing, FJDynamics also offers robotics solutions for grass collection, line marking, and ball picking, covering various landscaping and gardening scenarios from golf courses to tennis courts. With its automation solutions widely applied in more than 30 countries and regions, FJDynamics aims to automate greenspace workflows in a more affordable and efficient way. Visit FJDynamics official website for more information.

About FJDynamics

FJDynamics is a robotics company focused on digitalization, automation, and new energy. We are committed to creating practical and affordable robots for the most labor-intensive industries and using our technology to drive AI adoption across sectors for improved productivity and working environment. Today, our solutions are widely applied in agriculture, landscaping, construction, surveying, and facility services. As our business expands globally, we are excited to collaborate with partners and clients to create a better future for the world.

** The press release content is from PR Newswire. Bastille Post is not involved in its creation. **

FJDynamics Introduces Eco-friendly Robotic Solutions for Lawn Care and Maintenance