|

SEOUL, South Korea, April 30, 2025 /PRNewswire/ -- LG unveiled the Dream Factory, a hub for the production of FC-BGAs (Flip Chip Ball Grid Arrays), the company's next-generation growth engine, to the media for the first time and announced it on the 30th April.

In 2022, LG Innotek announced its plans to launch a business producing FC-BGAs, high-value semiconductor substrates. To build the Dream Factory, the company acquired LG Electronics' Gumi 4 Factory and began full-scale mass production in February 2024.

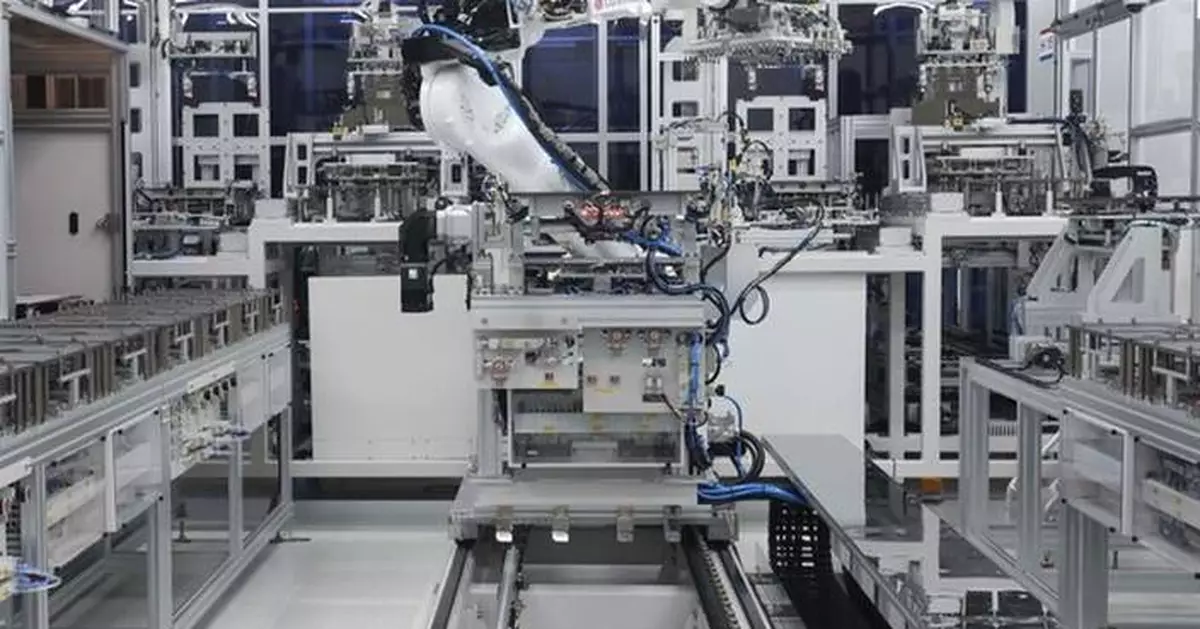

The Dream Factory, spanning a total area of 26,000 square meters, is regarded as the industry's most advanced "smart" factory, integrating the latest IT technologies, including artificial intelligence, deep learning, robotics, and digital twin technologies. By applying automation, information, and intelligence technologies to the entire process, it has established a cutting-edge FC-BGA production infrastructure that eliminates the four major factors known to undermine production competitiveness: human error (Man), failure cost (F-cost), breakdown maintenance (BM) loss, and accidents.

- "Elimination of defects caused by human contact" through automation of all processes and logistics using robots

For semiconductor substrate products such as FC-BGAs, which require a highly demanding ultra-fine process, even the smallest foreign objects (eyelash, saliva, etc.) can cause quality issues. Therefore, it is crucial to minimize human contact with products during production.

To this end, LG Innotek has introduced a completely automated logistics system at the Dream Factory, where coming across a person is a rare event. Apart from essential personnel, such as equipment maintenance and repair workers, all 10 steps of the FC-BGA production and logistics processes are unmanned.

Dozens of autonomous mobile robots (AMRs) move materials around the production line autonomously. When a production order is placed, which is done automatically, based on the customer's delivery timeframe entered in the RTS (real-time schedule), the AMRs transport the raw materials to the process facility. Once the barcode on the raw material is detected, also done automatically, by the machine, the process recipe is automatically set on the equipment according to the product specifications through the recipe management system (RMS), after which the product processing begins. The AMRs are also responsible for loading the finished product back into the stocker.

In addition, the process of peeling off the protective film from the panel (film detach) is also replaced by a robot. This enables the early prevention of fine scratches and defects caused by foreign objects such as dust particles and foreign substances. The construction of non-touch production facilities, involving such equipment as collaborative robots, in the entire process has significantly reduced mishandling by workers.

- Unmanned AI-based FC-BGA quality inspection, enhancing customer confidence by ensuring quality "transparency"

The Dream Factory generates more than 200,000 files and 100GB of data related to FC-BGA production every day. LG Innotek collects this data throughout the production process through sensors installed in all of its facilities. By applying AI, which continuously learns from this big data, to the defect prediction and inspection system, the company has significantly reduced the lead time caused by defects.

In addition, LG Innotek has applied an AI deep learning vision inspection system to the Automated Optical Inspection (AOI) process, which is the most important step in determining whether a product is of good quality. Tirelessly, the robot moves the finished FC-BGA board products to the vision screening inspection table. Next, the AI, which has been trained on tens of thousands of data points on defective and good quality FC-BGAs, detects micro-level defects that are challenging to identify with the naked eye, and it does so in only 30 seconds.

LG Innotek is operating a further advanced AOI process. In the room next to the AOI equipment for faulty circuits, there is a much larger robot and inspection system. Called Line Quality Control (LQC), it can automatically check whether the various specifications (thickness, size, etc.) of the product requested by the customer have been fulfilled. The inspection data is immediately sent to the customer, ensuring product quality transparency, which leads to higher customer confidence. This industry-leading sophistication of LG Innotek's AOI equipment has been cited as one of the most impressive aspects of the factory by the global customers who have visited it.

AI can identify defective products, and since every product has a barcode that tracks its process history, products that are deemed defective are automatically filtered out without the need for human intervention, reducing F-costs by more than 50%.

Additionally, AI has been applied to the digital simulation system, which prevents product defects and equipment failures. Previously, the process of workers manually checking products for defects and identifying which machines were faulty and how to repair them in response to defects required a lot of time. This can now be significantly improved.

By 2026, LG Innotek plans to introduce an intelligent Quality Management System (i-QMS) that detects and analyzes quality irregularities during production in real time and automatically corrects them. The company plans to automate the entire FC-BGA production process, especially by developing a platform that uses digital twin technology to share information on all processes, from product development to production, with customers in real time to enhance customer responsiveness.

- Optimized FC-BGA process equipment using digital twin technology, "halving the ramp-up period"

Since even the smallest variables can lead to poor performance in FC-BGAs, equipment optimized for mass production and process recipes and production environments set to perfect values are fundamental to achieving high yields.

The FC-BGA process equipment installed in the Dream Factory is set to optimal conditions through digital twin technology. In the past, identifying optimal conditions for the FC-BGA process required a lot of time and money, along with hundreds of tests. Before building the facility, LG Innotek managed to identify problems with the initial setup of the FC-BGA process facility in advance by conducting a "factory simulation" using 3D modelling in virtual space. This enabled the facility to be carefully set for optimal conditions, such as liquid, heat, and air flow, which were difficult to measure inside the actual facility. As a result, the ramp-up period (increase in production capacity by improving initial production yields) was shortened by nearly half compared to the previous operation period.

In addition, digital twin technology is applied to the Line Monitoring System (LMS), which monitors production status in real time. The real-time monitoring system enables users to monitor the production line currently in operation, product movement, inventory status, equipment irregularities, production performance, and product quality status at a glance on the large screen of the integrated control room where the LMS is installed. This makes it possible to respond immediately in the event of any irregularity.

- Internalization of glass core technology, step-by-step entry into the high-end FC-BGA market: "Fostering the business into 700 million USD business by 2030"

Over the past 50 years, LG Innotek has accumulated core technologies for high-value semiconductor substrates, such as ultra-fine microcircuits and high-density, multi-layer substrate matching technology (stacking multiple substrate layers accurately and evenly), through its substrate material components business.

Based on this know-how, the company began full-scale mass production of FC-BGAs for personal computers (PCs) for North American big-tech customers at the end of last year and recently succeeded in securing additional global big-tech clients. This year, LG Innotek aims to enter the FC-BGA market for PC central processing units (CPUs). Its strategy is to enter the high-end FC-BGA market in phases, including entering the server FC-BGA market as early as 2026. In preparation for this, LG Innotek has already acquired facilities that are essential in the manufacturing of FC-BGA products for servers, such as "edge coating" that blocks the generation of dust particles.

In line with this goal, LG Innotek will also accelerate the development of next-generation substrate technologies in collaboration with global big-tech clients. By 2027, the company plans to internalize technologies such as re-distribution layer (RDL) technology, which engraves microcircuit patterns directly onto the substrate; device embedding technology, which minimizes power loss by embedding devices into the substrate; and multi-layer core (MLC) and glass core (glass substrate) technologies, which prevent warping when implementing large-area substrates. In particular, LG Innotek has been promoting glass substrates by strengthening its collaboration with global customers.

Minseok Kang, vice president and head of LG Innotek's Substrate & Material Business Unit, said, "LG Innotek will continue to expand the production of FC-BGAs that provide exceptional customer value based on its state-of-the-art Dream Factory and develop the FC-BGA business into 700 million USD business by 2030."

According to the Fuji Chimera Research Institute, the size of the global FC-BGA market is expected to more than double from USD 8 billion in 2022 to USD 16.4 billion in 2030.

[Glossary]

FC-BGA (Flip Chip Ball Grid Array): This is a semiconductor substrate that is widely applied to electronic devices equipped with semiconductor chips (CPU, GPU, AI chips, etc.) that perform various computing functions. Demand for high-performance semiconductor substrates is growing rapidly due to increased data throughput, higher semiconductor processing speeds, and the need for low-power semiconductors. For these reasons, FC-BGAs have a larger area and more layers than conventional semiconductor substrates. They are also known to have high barriers to market entry because they require top-level facilities and technologies to produce.

SEOUL, South Korea, April 30, 2025 /PRNewswire/ -- LG unveiled the Dream Factory, a hub for the production of FC-BGAs (Flip Chip Ball Grid Arrays), the company's next-generation growth engine, to the media for the first time and announced it on the 30th April.

In 2022, LG Innotek announced its plans to launch a business producing FC-BGAs, high-value semiconductor substrates. To build the Dream Factory, the company acquired LG Electronics' Gumi 4 Factory and began full-scale mass production in February 2024.

The Dream Factory, spanning a total area of 26,000 square meters, is regarded as the industry's most advanced "smart" factory, integrating the latest IT technologies, including artificial intelligence, deep learning, robotics, and digital twin technologies. By applying automation, information, and intelligence technologies to the entire process, it has established a cutting-edge FC-BGA production infrastructure that eliminates the four major factors known to undermine production competitiveness: human error (Man), failure cost (F-cost), breakdown maintenance (BM) loss, and accidents.

- "Elimination of defects caused by human contact" through automation of all processes and logistics using robots

For semiconductor substrate products such as FC-BGAs, which require a highly demanding ultra-fine process, even the smallest foreign objects (eyelash, saliva, etc.) can cause quality issues. Therefore, it is crucial to minimize human contact with products during production.

To this end, LG Innotek has introduced a completely automated logistics system at the Dream Factory, where coming across a person is a rare event. Apart from essential personnel, such as equipment maintenance and repair workers, all 10 steps of the FC-BGA production and logistics processes are unmanned.

Dozens of autonomous mobile robots (AMRs) move materials around the production line autonomously. When a production order is placed, which is done automatically, based on the customer's delivery timeframe entered in the RTS (real-time schedule), the AMRs transport the raw materials to the process facility. Once the barcode on the raw material is detected, also done automatically, by the machine, the process recipe is automatically set on the equipment according to the product specifications through the recipe management system (RMS), after which the product processing begins. The AMRs are also responsible for loading the finished product back into the stocker.

In addition, the process of peeling off the protective film from the panel (film detach) is also replaced by a robot. This enables the early prevention of fine scratches and defects caused by foreign objects such as dust particles and foreign substances. The construction of non-touch production facilities, involving such equipment as collaborative robots, in the entire process has significantly reduced mishandling by workers.

- Unmanned AI-based FC-BGA quality inspection, enhancing customer confidence by ensuring quality "transparency"

The Dream Factory generates more than 200,000 files and 100GB of data related to FC-BGA production every day. LG Innotek collects this data throughout the production process through sensors installed in all of its facilities. By applying AI, which continuously learns from this big data, to the defect prediction and inspection system, the company has significantly reduced the lead time caused by defects.

In addition, LG Innotek has applied an AI deep learning vision inspection system to the Automated Optical Inspection (AOI) process, which is the most important step in determining whether a product is of good quality. Tirelessly, the robot moves the finished FC-BGA board products to the vision screening inspection table. Next, the AI, which has been trained on tens of thousands of data points on defective and good quality FC-BGAs, detects micro-level defects that are challenging to identify with the naked eye, and it does so in only 30 seconds.

LG Innotek is operating a further advanced AOI process. In the room next to the AOI equipment for faulty circuits, there is a much larger robot and inspection system. Called Line Quality Control (LQC), it can automatically check whether the various specifications (thickness, size, etc.) of the product requested by the customer have been fulfilled. The inspection data is immediately sent to the customer, ensuring product quality transparency, which leads to higher customer confidence. This industry-leading sophistication of LG Innotek's AOI equipment has been cited as one of the most impressive aspects of the factory by the global customers who have visited it.

AI can identify defective products, and since every product has a barcode that tracks its process history, products that are deemed defective are automatically filtered out without the need for human intervention, reducing F-costs by more than 50%.

Additionally, AI has been applied to the digital simulation system, which prevents product defects and equipment failures. Previously, the process of workers manually checking products for defects and identifying which machines were faulty and how to repair them in response to defects required a lot of time. This can now be significantly improved.

By 2026, LG Innotek plans to introduce an intelligent Quality Management System (i-QMS) that detects and analyzes quality irregularities during production in real time and automatically corrects them. The company plans to automate the entire FC-BGA production process, especially by developing a platform that uses digital twin technology to share information on all processes, from product development to production, with customers in real time to enhance customer responsiveness.

- Optimized FC-BGA process equipment using digital twin technology, "halving the ramp-up period"

Since even the smallest variables can lead to poor performance in FC-BGAs, equipment optimized for mass production and process recipes and production environments set to perfect values are fundamental to achieving high yields.

The FC-BGA process equipment installed in the Dream Factory is set to optimal conditions through digital twin technology. In the past, identifying optimal conditions for the FC-BGA process required a lot of time and money, along with hundreds of tests. Before building the facility, LG Innotek managed to identify problems with the initial setup of the FC-BGA process facility in advance by conducting a "factory simulation" using 3D modelling in virtual space. This enabled the facility to be carefully set for optimal conditions, such as liquid, heat, and air flow, which were difficult to measure inside the actual facility. As a result, the ramp-up period (increase in production capacity by improving initial production yields) was shortened by nearly half compared to the previous operation period.

In addition, digital twin technology is applied to the Line Monitoring System (LMS), which monitors production status in real time. The real-time monitoring system enables users to monitor the production line currently in operation, product movement, inventory status, equipment irregularities, production performance, and product quality status at a glance on the large screen of the integrated control room where the LMS is installed. This makes it possible to respond immediately in the event of any irregularity.

- Internalization of glass core technology, step-by-step entry into the high-end FC-BGA market: "Fostering the business into 700 million USD business by 2030"

Over the past 50 years, LG Innotek has accumulated core technologies for high-value semiconductor substrates, such as ultra-fine microcircuits and high-density, multi-layer substrate matching technology (stacking multiple substrate layers accurately and evenly), through its substrate material components business.

Based on this know-how, the company began full-scale mass production of FC-BGAs for personal computers (PCs) for North American big-tech customers at the end of last year and recently succeeded in securing additional global big-tech clients. This year, LG Innotek aims to enter the FC-BGA market for PC central processing units (CPUs). Its strategy is to enter the high-end FC-BGA market in phases, including entering the server FC-BGA market as early as 2026. In preparation for this, LG Innotek has already acquired facilities that are essential in the manufacturing of FC-BGA products for servers, such as "edge coating" that blocks the generation of dust particles.

In line with this goal, LG Innotek will also accelerate the development of next-generation substrate technologies in collaboration with global big-tech clients. By 2027, the company plans to internalize technologies such as re-distribution layer (RDL) technology, which engraves microcircuit patterns directly onto the substrate; device embedding technology, which minimizes power loss by embedding devices into the substrate; and multi-layer core (MLC) and glass core (glass substrate) technologies, which prevent warping when implementing large-area substrates. In particular, LG Innotek has been promoting glass substrates by strengthening its collaboration with global customers.

Minseok Kang, vice president and head of LG Innotek's Substrate & Material Business Unit, said, "LG Innotek will continue to expand the production of FC-BGAs that provide exceptional customer value based on its state-of-the-art Dream Factory and develop the FC-BGA business into 700 million USD business by 2030."

According to the Fuji Chimera Research Institute, the size of the global FC-BGA market is expected to more than double from USD 8 billion in 2022 to USD 16.4 billion in 2030.

[Glossary]

FC-BGA (Flip Chip Ball Grid Array): This is a semiconductor substrate that is widely applied to electronic devices equipped with semiconductor chips (CPU, GPU, AI chips, etc.) that perform various computing functions. Demand for high-performance semiconductor substrates is growing rapidly due to increased data throughput, higher semiconductor processing speeds, and the need for low-power semiconductors. For these reasons, FC-BGAs have a larger area and more layers than conventional semiconductor substrates. They are also known to have high barriers to market entry because they require top-level facilities and technologies to produce.

** The press release content is from PR Newswire. Bastille Post is not involved in its creation. **

LG Innotek to build FC-BGA into 700 million USD business by 2030 with its state-of-the-art Dream Factory

|

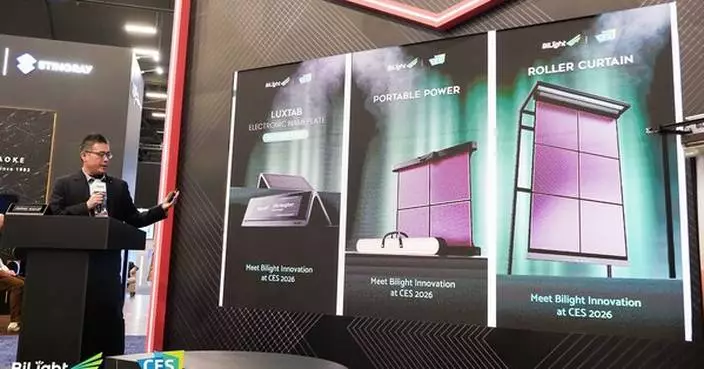

- Innovative technologies enable retailers to implement intelligent stores at scale to deliver smarter, more responsive shopping experiences

- Industry partners to display production-ready AI solutions for loss prevention, digital twins, AI agents, customer analytics, and more

SAN JOSE, Calif. and NEW YORK, Jan. 11, 2026 /PRNewswire/ -- Retail's Big Show -- Super Micro Computer, Inc. (SMCI), a Total IT Solution Provider for AI/ML, HPC, Cloud, Storage, and 5G/Edge, today announced collaboration with technology partners for AI-powered intelligent in-store retail solutions designed to meet increasing customer expectations with scalability, improved productivity and increased profitability.

"AI is reshaping shopping experiences, enabling real-time analysis of video and other data to give retailers actionable insights to optimizing staff efficiency, reducing shrinkage, increasing profits, and avoiding stock-outs," said Charles Liang, president and CEO of Supermicro. "By combining Supermicro's complete and scalable AI platforms with NVIDIA RTX PRO accelerated computing solutions, we're enabling retailers to build intelligent stores that maximize the benefits of AI-driven applications."

According to the latest NVIDIA State of AI in Retail & CPG report, 89% of respondents reported that AI is helping to increase annual revenue, while 95% said it is helping decrease annual costs, highlighting the measurable business impact retailers are already achieving because of AI1.

For more information, please visit https://www.supermicro.com/en/products/edge/servers

Supermicro Complete and Scalable Edge AI Infrastructure

Retail-centric AI applications require sub-second responsiveness which is only possible, at scale, if data is processed directly at the edge. Supermicro's Edge AI infrastructure enables the deployment of solutions in distributed environments, such as intelligent retail stores and supply chains, to provide a complete solution.

Deploying at the edge presents a myriad of unique challenges in comparison to the data center. Supermicro's broad Edge AI portfolio of products helps customers and partners overcome these challenges while striking the right balance between performance and ROI.

For deployments in harsh environments where conditioned space is not available, the fanless E103 series of products bring AI processing power where it couldn't go before. Supermicro also offers a fanned small form factor E300 series systems with AI capabilities.

When there is a demanding AI workload at the edge, customers and partners can turn to numerous systems capable of holding the latest discrete GPUs for AI acceleration. Ranging from 1U short-depth to larger 4U form factors, solutions can be right-sized to meet the customer's needs by enabling the latest generation of NVIDIA RTX PRO Blackwell series.

Supermicro Intelligent Store Partners

Supermicro is collaborating with ecosystem partners including Everseen, Kinetic Vision, ALLSIDES, LiveX, WobotAI, and Aible, to create intelligent stores that positively impact day-to-day retail operations as well as longer term supply chain management.

- Everseen's Evercheck solution uses Vision AI to help reduce shrink and improve staff productivity and customer experiences. Built on the Everseen Vision AI platform, Evercheck detects, and deters recovery of unwanted behaviors at checkout, helping retailers recover losses and streamline front-of-store operations.

"Everseen has spent years working alongside some of the world's largest retailers, understanding the realities of the store floor and solving loss challenges where they actually happen," said Joe White, CEO of Everseen. "By partnering with Supermicro and leveraging NVIDIA-accelerated computing, Evercheck delivers real-time computer vision at the edge - transforming store activity into intelligence retailers can act on immediately."

- Wobot AI, focused on building Video AI Agents for the physical world, will be demonstrating how the cameras retailers already own can be turned into systems that continuously observe, learn, and produce usable insight. By converting ordinary CCTV infrastructure into autonomous agents that recognize patterns, identify friction, and surface decisions, Wobot's AI Agents enable retailers to improve day-to-day operations with practical and measurable outcomes.

"By working with Supermicro and NVIDIA at the edge, we're able to deploy Video AI Agents in a way that's scalable, reliable, and focused on real-time operational insight—not experimentation," said Will Kelso, President, Revenue & Growth at Wobot AI.

- LiveX AI - "Retail is entering an era where AI agents become the default interaction layer between brands and customers," said Jerry Li, Co-Founder and CEO of LiveX AI. "With NVIDIA's accelerated AI and Supermicro's edge infrastructure, we can deploy a helpful, human-like AI agent directly in physical spaces—such as kiosks or holograms—bringing the speed, intelligence, and continuity of digital experiences into brick-and-mortar environments. This collaboration makes AI agents usable, in real time, where customers actually are."

-

- Kinetic Vision and ALLSIDES are bundling their expertise for a True Digital Twin solution designed to develop, test, and optimize supply chain processes, checkout stations, and other complex systems.

"The combination of Supermicro's high reliability optimized infrastructure and NVIDIA's accelerated computing stack gives Kinetic Vision the foundation to innovate at speed. Together, we are helping retailers move from experimentation to production-ready AI solutions that drive measurable operational and customer experience gains," says Jeremy Jarratt, Kinetic Vision CEO.

Franz Tschimben, CEO at ALLSIDES, adds: "Building on the combined strengths of NVIDIA and Supermicro, we deliver a high-fidelity 3D digital twin data layer for AI training that enables retailers to power applications across the entire retail value chain — from training robots with physical AI, to production and production planning, virtual store layouts and consumer feedback systems, and e-commerce integrations — helping drive higher conversion rates, faster decision-making, and greater operational efficiency."

- Supermicro will also feature Superb AI's retail-focused VSS solution, combining Superb AI's proprietary VLM with NVIDIA AI Blueprint components to enable subjective reasoning capabilities, natural-language search, automated incident summarization, and customer behavior insights across store camera networks.

- Aible will highlight its automated agent solution, which analyzes vast amounts of data across millions of patterns to explain changes in retail KPIs, such as the average purchase amount or number of purchases. Aible will also demonstrate how the latest NVIDIA Retail blueprints can be incorporated into agentic solutions that automatically customize customer experiences and optimize retail operations at scale.

Arijit Sengupta, CEO of Aible, adds, "Today's market and labor conditions are constantly changing. Only autonomous agents can understand and adjust to these ever-changing patterns of customer behavior, inventory costs and supply, and labor access at scale. Working with NVIDIA and Supermicro, Aible brings autonomous agents subject to business user review to the retail edge."

These intelligent retail solutions will be demonstrated by Supermicro and its partners at NRF: Retail's Big Show in New York City from January 11-13. To learn more about AI-powered retail applications or Supermicro's AI Infrastructure solutions, visit Supermicro booth #5281 and attend its speaking session featuring PepsiCo and Kinetic Vision. For more details, please visit www.supermicro.com/NRF

1Source: "NVIDIA State of AI in Retail and CPG" 2026

About Super Micro Computer, Inc.

Supermicro (NASDAQ: SMCI) is a global leader in Application-Optimized Total IT Solutions. Founded and operating in San Jose, California, Supermicro is committed to delivering first to market innovation for Enterprise, Cloud, AI, and 5G Telco/Edge IT Infrastructure. We are a Total IT Solutions provider with server, AI, storage, IoT, switch systems, software, and support services. Supermicro's motherboard, power, and chassis design expertise further enables our development and production, enabling next generation innovation from cloud to edge for our global customers. Our products are designed and manufactured in-house (in the US, Asia, and the Netherlands), leveraging global operations for scale and efficiency and optimized to improve TCO and reduce environmental impact (Green Computing). The award-winning portfolio of Server Building Block Solutions® allows customers to optimize for their exact workload and application by selecting from a broad family of systems built from our flexible and reusable building blocks that support a comprehensive set of form factors, processors, memory, GPUs, storage, networking, power, and cooling solutions (air-conditioned, free air cooling or liquid cooling).

Supermicro, Server Building Block Solutions, and We Keep IT Green are trademarks and/or registered trademarks of Super Micro Computer, Inc.

All other brands, names, and trademarks are the property of their respective owners.

- Innovative technologies enable retailers to implement intelligent stores at scale to deliver smarter, more responsive shopping experiences

- Industry partners to display production-ready AI solutions for loss prevention, digital twins, AI agents, customer analytics, and more

SAN JOSE, Calif. and NEW YORK, Jan. 11, 2026 /PRNewswire/ -- Retail's Big Show -- Super Micro Computer, Inc. (SMCI), a Total IT Solution Provider for AI/ML, HPC, Cloud, Storage, and 5G/Edge, today announced collaboration with technology partners for AI-powered intelligent in-store retail solutions designed to meet increasing customer expectations with scalability, improved productivity and increased profitability.

"AI is reshaping shopping experiences, enabling real-time analysis of video and other data to give retailers actionable insights to optimizing staff efficiency, reducing shrinkage, increasing profits, and avoiding stock-outs," said Charles Liang, president and CEO of Supermicro. "By combining Supermicro's complete and scalable AI platforms with NVIDIA RTX PRO accelerated computing solutions, we're enabling retailers to build intelligent stores that maximize the benefits of AI-driven applications."

According to the latest NVIDIA State of AI in Retail & CPG report, 89% of respondents reported that AI is helping to increase annual revenue, while 95% said it is helping decrease annual costs, highlighting the measurable business impact retailers are already achieving because of AI1.

For more information, please visit https://www.supermicro.com/en/products/edge/servers

Supermicro Complete and Scalable Edge AI Infrastructure

Retail-centric AI applications require sub-second responsiveness which is only possible, at scale, if data is processed directly at the edge. Supermicro's Edge AI infrastructure enables the deployment of solutions in distributed environments, such as intelligent retail stores and supply chains, to provide a complete solution.

Deploying at the edge presents a myriad of unique challenges in comparison to the data center. Supermicro's broad Edge AI portfolio of products helps customers and partners overcome these challenges while striking the right balance between performance and ROI.

For deployments in harsh environments where conditioned space is not available, the fanless E103 series of products bring AI processing power where it couldn't go before. Supermicro also offers a fanned small form factor E300 series systems with AI capabilities.

When there is a demanding AI workload at the edge, customers and partners can turn to numerous systems capable of holding the latest discrete GPUs for AI acceleration. Ranging from 1U short-depth to larger 4U form factors, solutions can be right-sized to meet the customer's needs by enabling the latest generation of NVIDIA RTX PRO Blackwell series.

Supermicro Intelligent Store Partners

Supermicro is collaborating with ecosystem partners including Everseen, Kinetic Vision, ALLSIDES, LiveX, WobotAI, and Aible, to create intelligent stores that positively impact day-to-day retail operations as well as longer term supply chain management.

- Everseen's Evercheck solution uses Vision AI to help reduce shrink and improve staff productivity and customer experiences. Built on the Everseen Vision AI platform, Evercheck detects, and deters recovery of unwanted behaviors at checkout, helping retailers recover losses and streamline front-of-store operations.

"Everseen has spent years working alongside some of the world's largest retailers, understanding the realities of the store floor and solving loss challenges where they actually happen," said Joe White, CEO of Everseen. "By partnering with Supermicro and leveraging NVIDIA-accelerated computing, Evercheck delivers real-time computer vision at the edge - transforming store activity into intelligence retailers can act on immediately."

- Wobot AI, focused on building Video AI Agents for the physical world, will be demonstrating how the cameras retailers already own can be turned into systems that continuously observe, learn, and produce usable insight. By converting ordinary CCTV infrastructure into autonomous agents that recognize patterns, identify friction, and surface decisions, Wobot's AI Agents enable retailers to improve day-to-day operations with practical and measurable outcomes.

"By working with Supermicro and NVIDIA at the edge, we're able to deploy Video AI Agents in a way that's scalable, reliable, and focused on real-time operational insight—not experimentation," said Will Kelso, President, Revenue & Growth at Wobot AI.

- LiveX AI - "Retail is entering an era where AI agents become the default interaction layer between brands and customers," said Jerry Li, Co-Founder and CEO of LiveX AI. "With NVIDIA's accelerated AI and Supermicro's edge infrastructure, we can deploy a helpful, human-like AI agent directly in physical spaces—such as kiosks or holograms—bringing the speed, intelligence, and continuity of digital experiences into brick-and-mortar environments. This collaboration makes AI agents usable, in real time, where customers actually are."

-

- Kinetic Vision and ALLSIDES are bundling their expertise for a True Digital Twin solution designed to develop, test, and optimize supply chain processes, checkout stations, and other complex systems.

"The combination of Supermicro's high reliability optimized infrastructure and NVIDIA's accelerated computing stack gives Kinetic Vision the foundation to innovate at speed. Together, we are helping retailers move from experimentation to production-ready AI solutions that drive measurable operational and customer experience gains," says Jeremy Jarratt, Kinetic Vision CEO.

Franz Tschimben, CEO at ALLSIDES, adds: "Building on the combined strengths of NVIDIA and Supermicro, we deliver a high-fidelity 3D digital twin data layer for AI training that enables retailers to power applications across the entire retail value chain — from training robots with physical AI, to production and production planning, virtual store layouts and consumer feedback systems, and e-commerce integrations — helping drive higher conversion rates, faster decision-making, and greater operational efficiency."

- Supermicro will also feature Superb AI's retail-focused VSS solution, combining Superb AI's proprietary VLM with NVIDIA AI Blueprint components to enable subjective reasoning capabilities, natural-language search, automated incident summarization, and customer behavior insights across store camera networks.

- Aible will highlight its automated agent solution, which analyzes vast amounts of data across millions of patterns to explain changes in retail KPIs, such as the average purchase amount or number of purchases. Aible will also demonstrate how the latest NVIDIA Retail blueprints can be incorporated into agentic solutions that automatically customize customer experiences and optimize retail operations at scale.

Arijit Sengupta, CEO of Aible, adds, "Today's market and labor conditions are constantly changing. Only autonomous agents can understand and adjust to these ever-changing patterns of customer behavior, inventory costs and supply, and labor access at scale. Working with NVIDIA and Supermicro, Aible brings autonomous agents subject to business user review to the retail edge."

These intelligent retail solutions will be demonstrated by Supermicro and its partners at NRF: Retail's Big Show in New York City from January 11-13. To learn more about AI-powered retail applications or Supermicro's AI Infrastructure solutions, visit Supermicro booth #5281 and attend its speaking session featuring PepsiCo and Kinetic Vision. For more details, please visit www.supermicro.com/NRF

1Source: "NVIDIA State of AI in Retail and CPG" 2026

About Super Micro Computer, Inc.

Supermicro (NASDAQ: SMCI) is a global leader in Application-Optimized Total IT Solutions. Founded and operating in San Jose, California, Supermicro is committed to delivering first to market innovation for Enterprise, Cloud, AI, and 5G Telco/Edge IT Infrastructure. We are a Total IT Solutions provider with server, AI, storage, IoT, switch systems, software, and support services. Supermicro's motherboard, power, and chassis design expertise further enables our development and production, enabling next generation innovation from cloud to edge for our global customers. Our products are designed and manufactured in-house (in the US, Asia, and the Netherlands), leveraging global operations for scale and efficiency and optimized to improve TCO and reduce environmental impact (Green Computing). The award-winning portfolio of Server Building Block Solutions® allows customers to optimize for their exact workload and application by selecting from a broad family of systems built from our flexible and reusable building blocks that support a comprehensive set of form factors, processors, memory, GPUs, storage, networking, power, and cooling solutions (air-conditioned, free air cooling or liquid cooling).

Supermicro, Server Building Block Solutions, and We Keep IT Green are trademarks and/or registered trademarks of Super Micro Computer, Inc.

All other brands, names, and trademarks are the property of their respective owners.

** The press release content is from PR Newswire. Bastille Post is not involved in its creation. **

Supermicro Announces Intelligent In-Store Retail Solutions in Collaboration with a Broad Range of Industry Partners