|

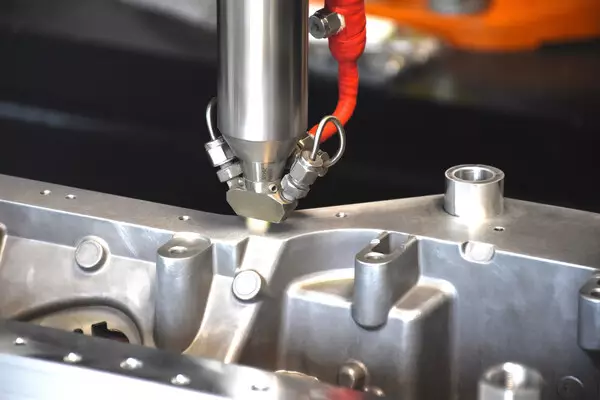

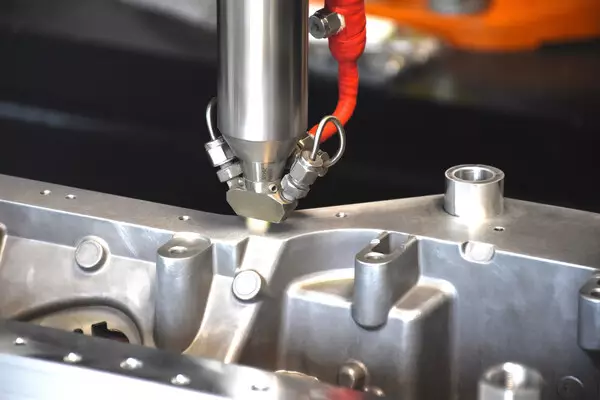

STEINHAGEN, Germany, April 30, 2025 /PRNewswire/ -- Plasmatreat's Openair-Plasma is used to specifically clean, activate or coat the surfaces of battery cells and housings. This creates perfect adhesion conditions for adhesives, paints, coatings and sealants - without the use of environmentally harmful solvents. The inline treatment, which takes only a few seconds, increases the quality, safety and efficiency of battery production and supports the development of sustainable mobility and energy storage solutions.

Plasmatreat GmbH of Germany develops systems for non-contact surface treatment using Openair-Plasma. This is a high-energy plasma beam that selectively cleans, activates or coats materials. In battery production, the technology ensures that components can be perfectly joined, painted or coated, and that adhesives, seals or insulating materials adhere to surfaces - without the use of solvents.

PlasmaPlus is a particularly innovative process. The plasma is enriched with special substances that form an ultra-thin protective layer when applied. These layers protect sensitive battery materials from corrosion, improve electrical insulation or serve as an environmentally friendly bonding agent. In cell production, when applying insulation, in module construction or when sealing battery housings, plasma technology offers advantages in terms of quality, efficiency and costs.

Further plus points: The treatment takes place directly in the production line - in a matter of seconds, precisely and automatically. This means that even large quantities can be processed efficiently. Plasma replaces time-consuming mechanical or chemical pre-treatment, reduces the consumption of resources and cuts down on waste, as all components are pre-treated evenly. Even particularly sensitive materials such as thin films can be treated gently and without damage.

"Our technology makes an important contribution to the quality and safety of battery systems," explains Lukas Buske, Managing Director at Plasmatreat. "Without perfect adhesion, there is no reliable battery – Openair-Plasma and PlasmaPlus make an important contribution to efficiency and quality in battery production, in seconds and without any chemicals."

Plasmatreat works with leading battery manufacturers and system builders worldwide - always with the aim of creating innovative solutions for a sustainable future.

What is Openair-Plasma?

Plasma is also known as the fourth state of matter, alongside solid, liquid and gas. When additional energy is added to a gas, it becomes ionized and enters the energetic plasma state. Whether plastic, metal, glass or paper, plasma technology is used to change the properties of the surface according to the requirements of the process.

Media contact

Plasmatreat GmbH:

Ms. Corinna Hokamp

pr@plasmatreat.com

STEINHAGEN, Germany, April 30, 2025 /PRNewswire/ -- Plasmatreat's Openair-Plasma is used to specifically clean, activate or coat the surfaces of battery cells and housings. This creates perfect adhesion conditions for adhesives, paints, coatings and sealants - without the use of environmentally harmful solvents. The inline treatment, which takes only a few seconds, increases the quality, safety and efficiency of battery production and supports the development of sustainable mobility and energy storage solutions.

Plasmatreat GmbH of Germany develops systems for non-contact surface treatment using Openair-Plasma. This is a high-energy plasma beam that selectively cleans, activates or coats materials. In battery production, the technology ensures that components can be perfectly joined, painted or coated, and that adhesives, seals or insulating materials adhere to surfaces - without the use of solvents.

PlasmaPlus is a particularly innovative process. The plasma is enriched with special substances that form an ultra-thin protective layer when applied. These layers protect sensitive battery materials from corrosion, improve electrical insulation or serve as an environmentally friendly bonding agent. In cell production, when applying insulation, in module construction or when sealing battery housings, plasma technology offers advantages in terms of quality, efficiency and costs.

Further plus points: The treatment takes place directly in the production line - in a matter of seconds, precisely and automatically. This means that even large quantities can be processed efficiently. Plasma replaces time-consuming mechanical or chemical pre-treatment, reduces the consumption of resources and cuts down on waste, as all components are pre-treated evenly. Even particularly sensitive materials such as thin films can be treated gently and without damage.

"Our technology makes an important contribution to the quality and safety of battery systems," explains Lukas Buske, Managing Director at Plasmatreat. "Without perfect adhesion, there is no reliable battery – Openair-Plasma and PlasmaPlus make an important contribution to efficiency and quality in battery production, in seconds and without any chemicals."

Plasmatreat works with leading battery manufacturers and system builders worldwide - always with the aim of creating innovative solutions for a sustainable future.

What is Openair-Plasma?

Plasma is also known as the fourth state of matter, alongside solid, liquid and gas. When additional energy is added to a gas, it becomes ionized and enters the energetic plasma state. Whether plastic, metal, glass or paper, plasma technology is used to change the properties of the surface according to the requirements of the process.

Media contact

Plasmatreat GmbH:

Ms. Corinna Hokamp

pr@plasmatreat.com

** The press release content is from PR Newswire. Bastille Post is not involved in its creation. **

Plasma makes the difference in the production of high-performance batteries

Plasma makes the difference in the production of high-performance batteries

|

All top five domestic destinations experienced positive growth in accommodation searches compared to previous year

SINGAPORE, Jan. 5, 2026 /PRNewswire/ -- Malaysian travelers are increasingly eyeing domestic destinations for December travel, reveals digital travel platform Agoda. The insight is based on accommodation searches made on the platform between September and November for stays during the holiday month 2025. The five most popular domestic destinations all recorded a higher number of searches compared to previous year, highlighting a growing interest for local trips during the year-end holiday period 2025.

Kuala Lumpur tops the list of domestic searches. Penang came in second, followed by Malacca, Kota Kinabalu, and Johor Bahru. All domestic destinations noted a double-digit increase in accommodation searches, with Kuala Lumpur noting the highest year-on-year increase with 18% more interest, indicating the strong appeal of trips close to home.

For Malaysian travelers looking abroad, Hat Yai, Bangkok, and Tokyo hold the top three ranks as most searched destinations, followed by Singapore and Phuket. The highest year-on-year increase in accommodation searches was noted by Krabi, Thailand (35%). South Korea's capital Seoul followed closely, with 33%.

Fabian Teja, Country Director Malaysia and Brunei at Agoda said, "The increasing enthusiasm among Malaysians for domestic travel is great to witness, considering the variety of incredible destinations right here at home. At the same time, the rising interest in destinations like Seoul and Krabi highlights the dynamic and diverse interest among Malaysian travelers. Whether they are planning a cozy getaway closer to home or getting ready for an exciting adventure abroad, Agoda is committed to offering great value deals to Malaysian travelers."

With over 130,000 flight routes, more than 6 million holiday properties, and over 300,000 activities, Agoda offers flexible options and deals to help travelers discover destinations that suit their plans and preferences. Discover the best deals on Agoda's mobile app and visit Agoda.com to plan the perfect year-end trips.

-- ENDS –

All top five domestic destinations experienced positive growth in accommodation searches compared to previous year

SINGAPORE, Jan. 5, 2026 /PRNewswire/ -- Malaysian travelers are increasingly eyeing domestic destinations for December travel, reveals digital travel platform Agoda. The insight is based on accommodation searches made on the platform between September and November for stays during the holiday month 2025. The five most popular domestic destinations all recorded a higher number of searches compared to previous year, highlighting a growing interest for local trips during the year-end holiday period 2025.

Kuala Lumpur tops the list of domestic searches. Penang came in second, followed by Malacca, Kota Kinabalu, and Johor Bahru. All domestic destinations noted a double-digit increase in accommodation searches, with Kuala Lumpur noting the highest year-on-year increase with 18% more interest, indicating the strong appeal of trips close to home.

For Malaysian travelers looking abroad, Hat Yai, Bangkok, and Tokyo hold the top three ranks as most searched destinations, followed by Singapore and Phuket. The highest year-on-year increase in accommodation searches was noted by Krabi, Thailand (35%). South Korea's capital Seoul followed closely, with 33%.

Fabian Teja, Country Director Malaysia and Brunei at Agoda said, "The increasing enthusiasm among Malaysians for domestic travel is great to witness, considering the variety of incredible destinations right here at home. At the same time, the rising interest in destinations like Seoul and Krabi highlights the dynamic and diverse interest among Malaysian travelers. Whether they are planning a cozy getaway closer to home or getting ready for an exciting adventure abroad, Agoda is committed to offering great value deals to Malaysian travelers."

With over 130,000 flight routes, more than 6 million holiday properties, and over 300,000 activities, Agoda offers flexible options and deals to help travelers discover destinations that suit their plans and preferences. Discover the best deals on Agoda's mobile app and visit Agoda.com to plan the perfect year-end trips.

-- ENDS –

** The press release content is from PR Newswire. Bastille Post is not involved in its creation. **

Agoda Reveals Growing Interest for Year-End Domestic Travel with Kuala Lumpur at the Forefront in 2025