YIWU, China, May 8, 2025 /PRNewswire/ -- With new U.S. tariff policies driving up the cost of importing and exporting industrial and consumer goods, global supply chains are facing increasing pressure. This shift is accelerating the transition toward localized, distributed manufacturing. In this new environment, 3D print farms—offering faster, more flexible, and cost-efficient production—are seeing unprecedented commercial opportunity.

Since 2023, 3D print farms have proven to be a highly profitable model in many countries. One standout example is Jinqi Toys, now the world's largest 3D print farm, which demonstrates just how efficient, scalable, and lucrative this approach can be. With 4,000 printers in operation, the company continues to expand at an impressive pace.

Jinqi Toys' Success Story

Founded in May 2023 in a small Chinese city with just $7,000 in startup capital, Jinqi Toys rose to global prominence in under 18 months, fueled by booming international demand. Today, its 3D-printed toys lead e-commerce rankings across Europe and North America.

"Our printers run 24/7, producing 50,000 sets a day, and we still can't keep up with demand," says Hao Zeng, founder of Jinqi. Their success stems from unique product designs, exclusive filament colors, high-speed stable printing, and rapid fulfillment—creating a powerful competitive edge and strong market appeal.

"As we grew, managing costs, ROI, and pricing became critical. Reliable, high-performance printers form the backbone of our business. At first, we simply followed trends and purchased whatever models were popular. But soon, we realized that not all printers are built to handle the demands of a print farm."

This realization led Jinqi to standardize their operations around Flashforge printers - Amazon's 2024 bestseller in the category.

"The Flashforge Adventurer 5M has been transformative for our business," Zeng emphasizes."The value for money is unbeatable. It's fast, uses a stable CoreXY structure, and delivers excellent print quality. One person can manage up to 500 printers via group control—it's incredibly efficient."

He adds: "During two sudden power outages, over 90% of our Adventurer 5M prints resumed flawlessly, with no visible seams. That saved us from major losses, while other brands' prints failed entirely."

Why Are 3D Print Farms Booming?

Just like fast fashion transformed the apparel industry, consumer goods and toy sectors are moving from mass production to small-batch, fast-changing product lines. Traditional manufacturing often requires high upfront investment, expensive molds, long lead times, and large labor forces. 3D printing eliminates these constraints, enabling rapid product iterations, flexible production, and seamless customization—especially for intricate designs and movable parts.

As one entrepreneur put it, "A friend started with a few printers, making small batches. As orders grew, he just added more printers and staff. It's a business model that scales easily."

Is it Profitable to Build a Small 3D Print Farm in Your Country?

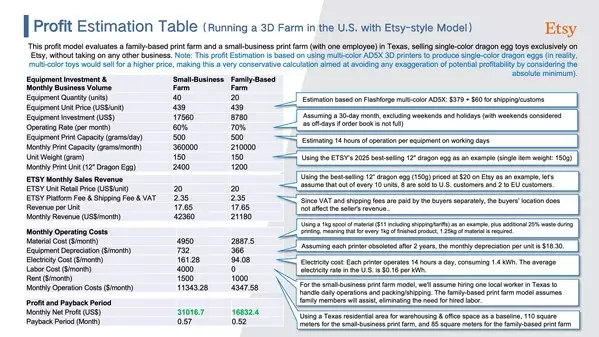

Jinqi Toys thrives on China's ultra-low costs—leveraging slim profit margins and large-scale production. But in Europe and North America, entrepreneurs can often achieve higher profit per unit, making solid returns with just a few dozen printers.

"If you're new to 3D printing, having a solid business plan is key to building a scalable, sustainable operation," says a Texas-based Etsy seller of 3D-printed dragon eggs."Start with the right printer, but also plan for space, customers, maintenance, labor, and ROI."

He's currently considering upgrading to the multicolor Adventurer 5X and shared this estimate based on real sales data (Please refer to table 1, which has been included in the white paper at the end):

Making over $30,000/month with just 40 printers. These cases clearly demonstrate that - with the rise of 3D printing and the impact of new tariffs - a new era of wealth creation through local, distributed manufacturing has begun.

Interested in starting your own 3D print farm?

Visit: https://flashforge.com/pages/3d-printing-farm

Or contact the following email to obtain the '3D Printing Industry White Paper':

** The press release content is from PR Newswire. Bastille Post is not involved in its creation. **

Opportunity Under New Tariff Policy: How 40 3D Printers Generated $30000 a Month

Opportunity Under New Tariff Policy: How 40 3D Printers Generated $30000 a Month