China is ramping up electric vehicle battery trials and testing projects, months ahead of a new mandatory national safety standard set to take effect next year.

Released by the Ministry of Industry and Information Technology, the "Safety Requirements for Power Batteries Used in Electric Vehicles (GB38031-2025)" introduces seven cell-level tests and 17 battery pack or system-level tests, marking a new benchmark for safety when it takes effect on July 1, 2026.

With stricter safety criteria compared to the 2020 version, the new regulations have prompted the New Energy Automotive Test Center (Tianjin) Co.—a subsidiary of the China Automotive Technology and Research Center (CATARC) and a top third-party testing institution in China—to align the majority of its experiments with the updated national standard.

"Safety requirements have become more stringent. For instance, the thermal diffusion requirement has been upgraded from providing a five-minute warning before a fire or explosion to no fire and no explosion at all. Additionally, the coverage of tests has been expanded. Corresponding safety tests have been set up for two risk scenarios: bottom support and long-term fast charging of vehicles," Hao Weijian, a senior engineer at the CATARC explained.

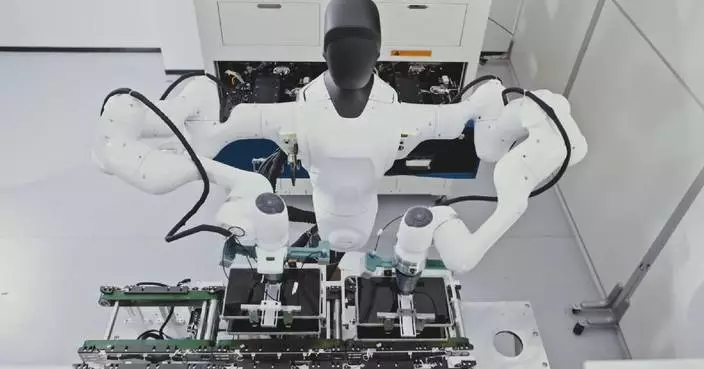

Jiang Chenlong, a senior engineer at the New Energy Automotive Test Center (Tianjin) Co., emphasized that the regulations’ core mandate requires batteries to resist ignition or explosion for at least two hours during thermal runaway, a self-heating state in lithium-ion cells responsible for most battery-related incidents.

"Generally, the temperature of a punctured battery can rise to around 300 degrees Celsius, and the internal temperature of the battery cell can reach approximately 1,000 degrees Celsius. During this process, the temperatures of adjacent batteries will also increase accordingly. However, during the diffusion process, the entire battery system must not catch fire or explode," Jiang explained.

A newly introduced bottom impact test evaluates the battery's protective capabilities by striking three vulnerable points, at the front, middle, and rear of its base, with 150 joules of energy using a steel impactor.

"These three risk points are mainly selected based on the areas where the battery pack's bottom protection is more sensitive. The goal of the test is to see how well the bottom can handle bumps," Jiang stated.

The revisions also added a new safety test following fast charging cycles, which requires external short circuit testing after 300 fast charge cycles, mandating no fire or explosion.

China enhances power battery testing ahead of new safety standard rollout