|

- Europe exits two-year slump, led by German export rebound and domestic demand recovery

- U.S. manufacturers purchasing surges ahead of U.S. 'tariff pause' ending

- Asia supply chains pick up, though capacity remains underutilized in Southeast Asia

- No signs of cost inflation escalation yet despite the 10% universal tariff imposed by the U.S.

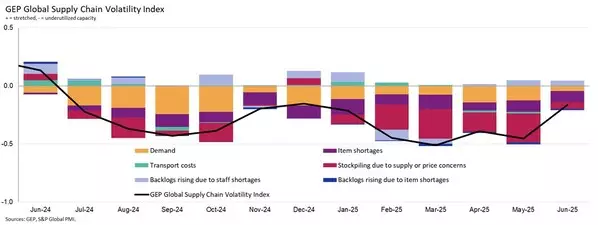

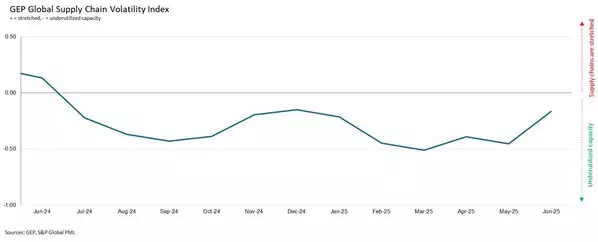

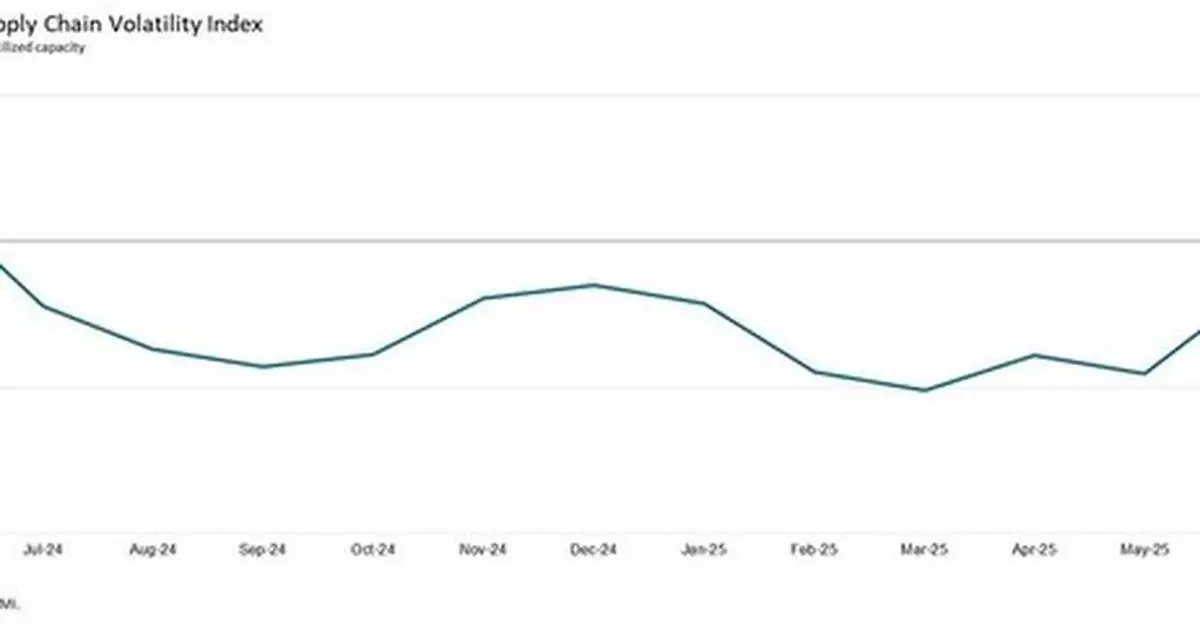

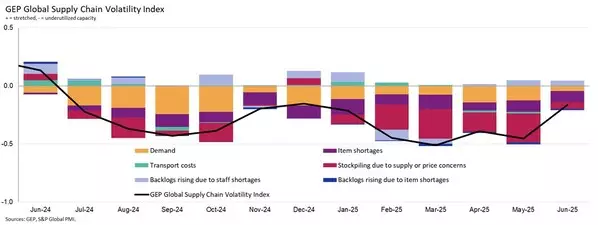

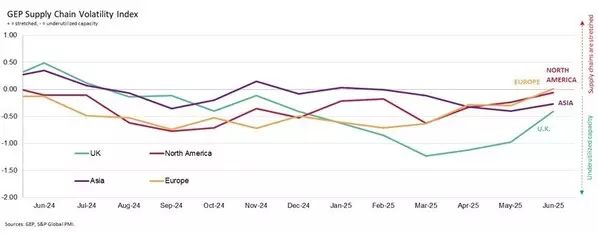

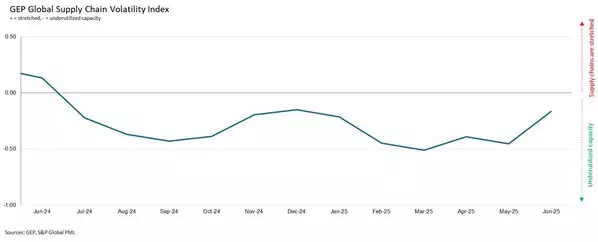

CLARK, N.J., July 11, 2025 /PRNewswire/ -- GEP Global Supply Chain Volatility Index — a leading indicator tracking demand conditions, shortages, transportation costs, inventories, and backlogs based on a monthly survey of 27,000 businesses — jumped to -0.17 in June, from -0.46 in May, its highest in 2025 as worldwide supply chain activity picked up despite the 10% tariffs imposed by the US administration.

For the first time in more than two years, European manufacturers operated at full tilt, driven by front-loaded orders from US customers, and a rebound in both domestic and export demand, particularly across Germany.

In North America, demand for inputs surged as U.S. manufacturers moved quickly to secure inputs – commodities, parts, components and raw materials – ahead of a potential end to the current tariff pause.

Asia's supply chains also showed signs of recovery, with stronger activity in India, Japan, and South Korea. However, spare capacity remains across Southeast Asia, where factory purchasing continues to lag, notably in China.

Notably, there is no evidence in the data of cost inflation escalating dramatically, despite the tariffs.

"In June, Europe shook off its long slump and global supply chains ran at full capacity — despite the uncertainty and on-and-off again tariffs," said John Piatek, VP, Consulting, GEP. "But under the surface, companies are putting in place contingencies: stockpiling inputs, reshaping supplier networks, near-shoring operations, and securing supply chain financing."

Interpreting the data:

Index > 0, supply chain capacity is being stretched. The further above 0, the more stretched supply chains are.

Index < 0, supply chain capacity is being underutilized. The further below 0, the more underutilized supply chains are.

Interpreting the data:

Index > 0, supply chain capacity is being stretched. The further above 0, the more stretched supply chains are.

Index < 0, supply chain capacity is being underutilized. The further below 0, the more underutilized supply chains are.

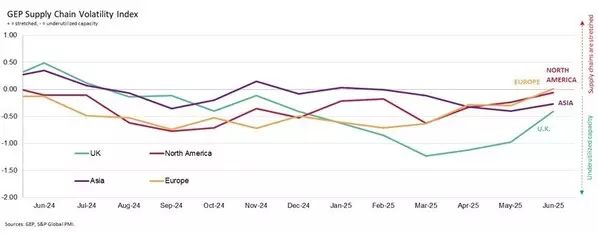

JUNE 2025 REGIONAL KEY FINDINGS

- ASIA: Index rises to -0.27, from -0.40, indicating a pick-up in Asian market activity, but the region's supply chains remain underutilized overall. This mostly reflects subdued factory conditions in Southeast Asia.

- NORTH AMERICA: Index rises to -0.06, from -0.24 as US manufacturers ramp up purchasing sharply ahead of the tariff pause coming to an end. North American supply chains effectively ran at full capacity in June.

- EUROPE: Index rises to 0.01, from -0.30, signaling full capacity utilization across Europe's supply chains in June as the continent's industrial sector emerges from its prolonged downturn.

- U.K.: Index rises to -0.41, from -0.97, its highest for seven months, but still indicative of an elevated level of slack across the U.K.'s supply chains.

JUNE 2025 KEY FINDINGS

- DEMAND: Global factory purchasing activity continued to trend upwards in June, with demand at its most robust in just over a year. This was driven by a considerable rise in North America, driven by the US, as manufacturers ramped up buying ahead of the pause on US tariffs coming to an end.

- INVENTORIES: There were increased reports from businesses of a rise in stockpiling due to price or supply concerns during June. Mentions of safety buffers being built into warehouses were their highest so far in 2025 globally, with the prospect of higher tariffs driving procurement managers into precautionary action.

- MATERIAL SHORTAGES: The global item shortages indicator, which measures the prevalence of supply problems, remains historically low, indicating robust availability.

- LABOR SHORTAGES: Suppliers' workforce capacity remains sufficient to process current order loads, according to our data. Reports of manufacturing backlogs rising due to staff shortages remain stable at historically typical levels.

- TRANSPORTATION: Global transportation costs were once again in line with their long-term average in June. Reports from surveyed businesses of logistic cost pressures remain anchored.

For more information, visit www.gep.com/volatility.

Note: Full historical data dating back to January 2005 is available for subscription. Please contact economics@spglobal.com.

The next release of the GEP Global Supply Chain Volatility Index will be 8 a.m. ET, Aug. 12, 2025.

About the GEP Global Supply Chain Volatility Index

The GEP Global Supply Chain Volatility Index is produced by S&P Global and GEP. It is derived from S&P Global's PMI® surveys, sent to companies in over 40 countries, totaling around 27,000 companies. The headline figure is a weighted sum of six sub-indices derived from PMI data, PMI Comments Trackers and PMI Commodity Price & Supply Indicators compiled by S&P Global. For more information about the methodology, click here.

About GEP

GEP® delivers AI-powered procurement and supply chain solutions that help global enterprises become more agile and resilient, operate more efficiently and effectively, gain competitive advantage, boost profitability and increase shareholder value. Headquartered in Clark, New Jersey, GEP has offices and operations centers across Europe, Asia, Africa and the Americas. To learn more, visit www.gep.com.

About S&P Global

S&P Global (NYSE: SPGI) S&P Global provides essential intelligence. We enable governments, businesses and individuals with the right data, expertise and connected technology so that they can make decisions with conviction. From helping our customers assess new investments to guiding them through ESG and energy transition across supply chains, we unlock new opportunities, solve challenges and accelerate progress for the world. We are widely sought after by many of the world's leading organizations to provide credit ratings, benchmarks, analytics and workflow solutions in the global capital, commodity and automotive markets. With every one of our offerings, we help the world's leading organizations plan for tomorrow, today.

- Europe exits two-year slump, led by German export rebound and domestic demand recovery

- U.S. manufacturers purchasing surges ahead of U.S. 'tariff pause' ending

- Asia supply chains pick up, though capacity remains underutilized in Southeast Asia

- No signs of cost inflation escalation yet despite the 10% universal tariff imposed by the U.S.

CLARK, N.J., July 11, 2025 /PRNewswire/ -- GEP Global Supply Chain Volatility Index — a leading indicator tracking demand conditions, shortages, transportation costs, inventories, and backlogs based on a monthly survey of 27,000 businesses — jumped to -0.17 in June, from -0.46 in May, its highest in 2025 as worldwide supply chain activity picked up despite the 10% tariffs imposed by the US administration.

For the first time in more than two years, European manufacturers operated at full tilt, driven by front-loaded orders from US customers, and a rebound in both domestic and export demand, particularly across Germany.

In North America, demand for inputs surged as U.S. manufacturers moved quickly to secure inputs – commodities, parts, components and raw materials – ahead of a potential end to the current tariff pause.

Asia's supply chains also showed signs of recovery, with stronger activity in India, Japan, and South Korea. However, spare capacity remains across Southeast Asia, where factory purchasing continues to lag, notably in China.

Notably, there is no evidence in the data of cost inflation escalating dramatically, despite the tariffs.

"In June, Europe shook off its long slump and global supply chains ran at full capacity — despite the uncertainty and on-and-off again tariffs," said John Piatek, VP, Consulting, GEP. "But under the surface, companies are putting in place contingencies: stockpiling inputs, reshaping supplier networks, near-shoring operations, and securing supply chain financing."

Interpreting the data:

Index > 0, supply chain capacity is being stretched. The further above 0, the more stretched supply chains are.

Index < 0, supply chain capacity is being underutilized. The further below 0, the more underutilized supply chains are.

Interpreting the data:

Index > 0, supply chain capacity is being stretched. The further above 0, the more stretched supply chains are.

Index < 0, supply chain capacity is being underutilized. The further below 0, the more underutilized supply chains are.

JUNE 2025 REGIONAL KEY FINDINGS

- ASIA: Index rises to -0.27, from -0.40, indicating a pick-up in Asian market activity, but the region's supply chains remain underutilized overall. This mostly reflects subdued factory conditions in Southeast Asia.

- NORTH AMERICA: Index rises to -0.06, from -0.24 as US manufacturers ramp up purchasing sharply ahead of the tariff pause coming to an end. North American supply chains effectively ran at full capacity in June.

- EUROPE: Index rises to 0.01, from -0.30, signaling full capacity utilization across Europe's supply chains in June as the continent's industrial sector emerges from its prolonged downturn.

- U.K.: Index rises to -0.41, from -0.97, its highest for seven months, but still indicative of an elevated level of slack across the U.K.'s supply chains.

JUNE 2025 KEY FINDINGS

- DEMAND: Global factory purchasing activity continued to trend upwards in June, with demand at its most robust in just over a year. This was driven by a considerable rise in North America, driven by the US, as manufacturers ramped up buying ahead of the pause on US tariffs coming to an end.

- INVENTORIES: There were increased reports from businesses of a rise in stockpiling due to price or supply concerns during June. Mentions of safety buffers being built into warehouses were their highest so far in 2025 globally, with the prospect of higher tariffs driving procurement managers into precautionary action.

- MATERIAL SHORTAGES: The global item shortages indicator, which measures the prevalence of supply problems, remains historically low, indicating robust availability.

- LABOR SHORTAGES: Suppliers' workforce capacity remains sufficient to process current order loads, according to our data. Reports of manufacturing backlogs rising due to staff shortages remain stable at historically typical levels.

- TRANSPORTATION: Global transportation costs were once again in line with their long-term average in June. Reports from surveyed businesses of logistic cost pressures remain anchored.

For more information, visit www.gep.com/volatility.

Note: Full historical data dating back to January 2005 is available for subscription. Please contact economics@spglobal.com.

The next release of the GEP Global Supply Chain Volatility Index will be 8 a.m. ET, Aug. 12, 2025.

About the GEP Global Supply Chain Volatility Index

The GEP Global Supply Chain Volatility Index is produced by S&P Global and GEP. It is derived from S&P Global's PMI® surveys, sent to companies in over 40 countries, totaling around 27,000 companies. The headline figure is a weighted sum of six sub-indices derived from PMI data, PMI Comments Trackers and PMI Commodity Price & Supply Indicators compiled by S&P Global. For more information about the methodology, click here.

About GEP

GEP® delivers AI-powered procurement and supply chain solutions that help global enterprises become more agile and resilient, operate more efficiently and effectively, gain competitive advantage, boost profitability and increase shareholder value. Headquartered in Clark, New Jersey, GEP has offices and operations centers across Europe, Asia, Africa and the Americas. To learn more, visit www.gep.com.

About S&P Global

S&P Global (NYSE: SPGI) S&P Global provides essential intelligence. We enable governments, businesses and individuals with the right data, expertise and connected technology so that they can make decisions with conviction. From helping our customers assess new investments to guiding them through ESG and energy transition across supply chains, we unlock new opportunities, solve challenges and accelerate progress for the world. We are widely sought after by many of the world's leading organizations to provide credit ratings, benchmarks, analytics and workflow solutions in the global capital, commodity and automotive markets. With every one of our offerings, we help the world's leading organizations plan for tomorrow, today.

Media Contacts

Derek Creevey

Joe Hayes

S&P Global Market Intelligence

Director, Public Relations

Principal Economist

Corporate Communications

GEP

S&P Global Market Intelligence

Email: Press.mi@spglobal.com

Phone: +1 646-276-4579

Phone: +44-1344-328-099

Email:

Email:

derek.creevey@gep.com

joe.hayes@spglobal.com

** The press release content is from PR Newswire. Bastille Post is not involved in its creation. **

TARIFF PAUSE SPURS GLOBAL MANUFACTURING ACTIVITY IN JUNE, WITH GLOBAL SUPPLY CHAINS NOW OPERATING CLOSE TO FULL CAPACITY: GEP GLOBAL SUPPLY CHAIN VOLATILITY INDEX

TARIFF PAUSE SPURS GLOBAL MANUFACTURING ACTIVITY IN JUNE, WITH GLOBAL SUPPLY CHAINS NOW OPERATING CLOSE TO FULL CAPACITY: GEP GLOBAL SUPPLY CHAIN VOLATILITY INDEX

TARIFF PAUSE SPURS GLOBAL MANUFACTURING ACTIVITY IN JUNE, WITH GLOBAL SUPPLY CHAINS NOW OPERATING CLOSE TO FULL CAPACITY: GEP GLOBAL SUPPLY CHAIN VOLATILITY INDEX

- All-new PALISADE honored by the North American Car, Utility and Truck of the Year (NACTOY) jury, one of the most respected independent automotive accolades

- Flagship three-row SUV praised for its hybrid and ICE powertrain lineup, class-above interior space, and advanced safety and convenience technologies

- NACTOY awards judged by 50 leading automotive journalists from the U.S. and Canada, following extensive real-world evaluation

SEOUL, South Korea and DETROIT, Jan. 15, 2026 /PRNewswire/ -- The all-new Hyundai PALISADE has been named the 2026 North American Utility Vehicle of the Year™ by the North American Car, Utility and Truck of the Year (NACTOY) jury, reaffirming Hyundai Motor's leadership in delivering family-focused SUVs with premium quality, advanced technology and everyday usability.

The NACTOY awards are determined by a jury of 50 independent automotive journalists from the U.S. and Canada, representing print, digital, television, radio and social media. Vehicles are evaluated through an extensive process, including long-term driving, comparative testing, and detailed assessments of design, performance, innovation, safety and value.

As Hyundai Motor's flagship three-row SUV, the all-new PALISADE was recognized for its broad and versatile powertrain lineup, including an efficient next-generation hybrid option alongside proven internal combustion engines. It also stood out for its spacious, premium interior, intuitive technology and comprehensive suite of family-oriented safety and convenience features.

"Palisade represents everything we strive to deliver at Hyundai — beautiful design, advanced technology, exceptional safety, and real value for families. To be recognized by 50 of North America's most respected automotive journalists as the best utility vehicle of the year is a tremendous honor. Thank you to our teams who made this possible, to our dealers who bring Palisade to life for customers every day, and to the NACTOY jury for this recognition." – José Muñoz, President and CEO, Hyundai Motor Company

"Hyundai PALISADE defines the family vehicle for the 21st century. It's spacious, fun to drive and has a lot of technology. Congratulations on this impressive win." – Jeff Gilbert, NACTOY President

Founded in 1994, NACTOY is the longest-running new-vehicle awards program not affiliated with a single media outlet. Its independence, rigorous evaluation process, and diverse jury make the awards among the most credible and prestigious honors in the global automotive industry.

More information about Hyundai Motor and its products can be found at: https://www.hyundai.com/worldwide/en/ or Newsroom: Media Hub by Hyundai

SEOUL, South Korea and DETROIT, Jan. 15, 2026 /PRNewswire/ -- The all-new Hyundai PALISADE has been named the 2026 North American Utility Vehicle of the Year™ by the North American Car, Utility and Truck of the Year (NACTOY) jury, reaffirming Hyundai Motor's leadership in delivering family-focused SUVs with premium quality, advanced technology and everyday usability.

The NACTOY awards are determined by a jury of 50 independent automotive journalists from the U.S. and Canada, representing print, digital, television, radio and social media. Vehicles are evaluated through an extensive process, including long-term driving, comparative testing, and detailed assessments of design, performance, innovation, safety and value.

As Hyundai Motor's flagship three-row SUV, the all-new PALISADE was recognized for its broad and versatile powertrain lineup, including an efficient next-generation hybrid option alongside proven internal combustion engines. It also stood out for its spacious, premium interior, intuitive technology and comprehensive suite of family-oriented safety and convenience features.

"Palisade represents everything we strive to deliver at Hyundai — beautiful design, advanced technology, exceptional safety, and real value for families. To be recognized by 50 of North America's most respected automotive journalists as the best utility vehicle of the year is a tremendous honor. Thank you to our teams who made this possible, to our dealers who bring Palisade to life for customers every day, and to the NACTOY jury for this recognition." – José Muñoz, President and CEO, Hyundai Motor Company

"Hyundai PALISADE defines the family vehicle for the 21st century. It's spacious, fun to drive and has a lot of technology. Congratulations on this impressive win." – Jeff Gilbert, NACTOY President

Founded in 1994, NACTOY is the longest-running new-vehicle awards program not affiliated with a single media outlet. Its independence, rigorous evaluation process, and diverse jury make the awards among the most credible and prestigious honors in the global automotive industry.

More information about Hyundai Motor and its products can be found at: https://www.hyundai.com/worldwide/en/ or Newsroom: Media Hub by Hyundai

** The press release content is from PR Newswire. Bastille Post is not involved in its creation. **

Hyundai PALISADE Crowned 2026 North American Utility Vehicle of the Year