Early Phase 1 monotherapy data demonstrate cytopenia-sparing safety, broad pharmacologic window, and early clinical activity in relapsed/refractory non-Hodgkin lymphoma (NHL)

TAIPEI, SHANGHAI, and SAN FRANCISCO, Dec. 8, 2025 /PRNewswire/ -- HanchorBio Inc. (TPEx: 7827), a global clinical-stage biotechnology company advancing next-generation immunotherapies for oncology and autoimmune diseases, today presented new first-in-human data from its ongoing Phase 1 monotherapy study of HCB101, a 3.5th-generation SIRPα-Fc fusion protein, in relapsed/refractory non-Hodgkin lymphoma (R/R NHL) at the 67th Annual Meeting of the American Society of Hematology (ASH), held December 6-9, 2025, in Orlando, Florida.

The ASH Annual Meeting is the world's premier platform for clinical and translational advances in hematology. This year, over 8,200 abstracts were accepted globally, reaffirming ASH's position as one of the most competitive and influential medical congresses in hematology and oncology, with historical rejection rates of approximately 28%.

The accepted abstract (#3299) features a focused sub-analysis from HanchorBio's ongoing multinational, open-label Phase 1 study (NCT05892718) evaluating HCB101 monotherapy across solid and hematologic malignancies, highlighting results from the R/R NHL cohort.

Key Results (data cutoff: October 14, 2025):

- Thirteen patients with R/R NHL received HCB101 (5.12 – 24.0 mg/kg QW). No dose-limiting toxicities (DLTs) were observed, and the maximum tolerated dose (MTD) was not reached.

- All treatment-related adverse events were Grade 1-2, confirming a cytopenia-sparing safety profile.

- CD47 receptor occupancy (RO) reached ≥ 75-85% at 1.2 mg/kg and ≥ 90% at 8 mg/kg, demonstrating a broad pharmacologic window.

- A confirmed partial response (PR) was observed in a patient with marginal zone B-cell lymphoma at 8.00 mg/kg, with -43.3% tumor reduction at Week 8 deepening to -89.5% by Week 16 at the same dose.

The results were presented by Alvin Luk, PhD, MBA, CCRA, President & Chief Medical Officer and Chief Executive Officer (U.S.) of HanchorBio during the ASH 2025 poster session. Dr. Luk recently joined HanchorBio to lead the company's global development of late-stage products and U.S. operations, advancing its next-generation immuno-oncology pipeline.

"Despite ASH's highly competitive selection process, the inclusion of HCB101 monotherapy data reflects the strong translational foundation and clinical potential of our SIRPα-CD47 backbone," said Scott Liu, Ph.D., Founder, Chairman, and Chief Executive Officer of HanchorBio. "We're encouraged by the favorable safety and early signs of clinical activity seen in the heavily pretreated patient population. These findings validate the translational strength of our FBDB™ platform, and we look forward to engaging with the global hematology community as we expand HCB101 into hematologic malignancies and macrophage/T-cell combination strategies."

"Presenting these data at ASH marks an important step for HanchorBio and our team," added Dr. Alvin Luk. "Moving from molecular design to early clinical validation highlights the potential of selective SIRPα-CD47 blockade to achieve both safety and effective immune activation in patients with limited treatment options."

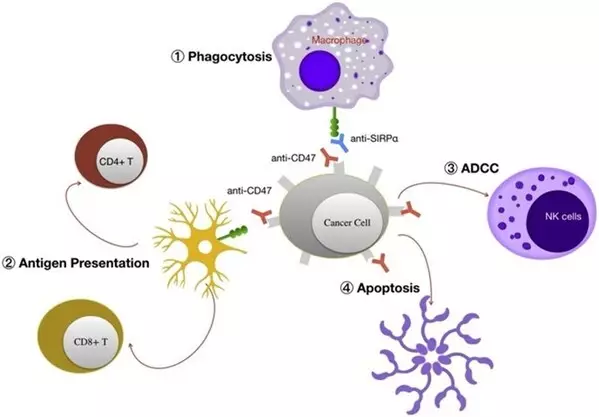

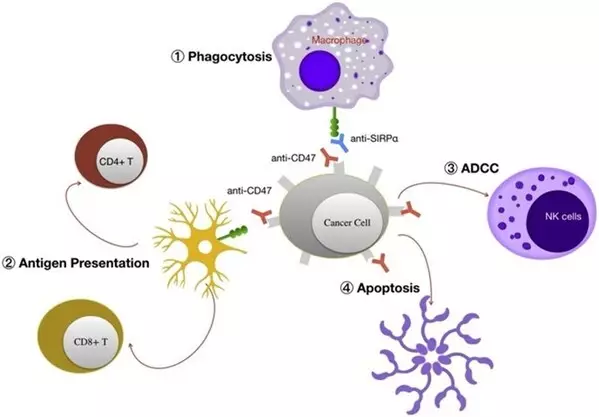

About HCB101: A Differentiated CD47-SIRPα Blockade

HCB101 is a 3.5th-generation, affinity-optimized SIRPα-Fc fusion protein with an intact IgG4 Fc backbone, developed using HanchorBio's proprietary FBDB™ platform. It is engineered for selective CD47 targeting with low red blood cell (RBC) binding, thereby avoiding the anemia and thrombocytopenia commonly associated with earlier anti-CD47 monoclonal antibodies, while preserving strong antibody-dependent cellular phagocytosis (ADCP) and innate-to-adaptive immune bridging. Key differentiators of HCB101:

- Enhanced safety: Cytopenia-sparing profile, with no DLTs observed up to 30 mg/kg and receptor occupancy >90% at ≥1.28 mg/kg, supporting a broad therapeutic window.

- Robust immune activation: Engineered to enhance ADCP and bridge innate-to-adaptive immunity, with evidence of durable immune-mediated tumor control in monotherapy.

- Broad tumor applicability: Demonstrated activity across >80 PDX and CDX preclinical models, with early clinical signals in gastric cancer, TNBC, HNSCC, non-Hodgkin lymphoma, and ovarian cancer.

- Clinical translation: Shows durable disease control as monotherapy and a 100% confirmed partial response rate (6/6) in 2L gastric cancer when combined with ramucirumab and paclitaxel, with additional confirmed responses in 1L TNBC and 2L HNSCC, substantially exceeding historical benchmarks.

About HanchorBio

Based in Taipei, Shanghai, and the San Francisco Bay Area, HanchorBio (TPEx: 7827) is a global biotechnology company specializing in immuno-oncology. It is led by an experienced team of pharmaceutical industry veterans with a proven track record in biologics discovery and international development, aiming to rewrite the landscape of cancer therapies. Committed to reactivating the immune system to fight diseases, the proprietary Fc-based designer biologics (FBDB™) platform enables the development of unique biologics with diverse multi-targeting modalities, unleashing both innate and adaptive immunity to overcome the current challenges of anti-PD1/L1 therapies. The FBDB™ platform has successfully delivered proof-of-concept data in several in vivo tumor animal models. By advancing breakthroughs in multi-functional, innovative molecular configurations in R&D and improving CMC manufacturing processes, HanchorBio develops transformative medicines to address unmet medical needs. For more information, please visit: https://www.HanchorBio.com

** The press release content is from PR Newswire. Bastille Post is not involved in its creation. **

HanchorBio Presents First-in-Human Data of HCB101 Monotherapy in Relapsed/Refractory Non-Hodgkin Lymphoma at ASH 2025

HanchorBio Presents First-in-Human Data of HCB101 Monotherapy in Relapsed/Refractory Non-Hodgkin Lymphoma at ASH 2025

|

The new imaging flagship series fuses advanced hardware with visionary TECNO AI to empower artistic creation, streamline daily life, and safeguard the digital experience.

BARCELONA, Spain, March 4, 2026 /PRNewswire/ -- AI-driven innovative technology brand TECNO today took the stage at MWC 2026 to unveil the CAMON 50 Series. Featuring the CAMON 50 Ultra 5G, CAMON 50 Pro, and CAMON 50, the lineup represents a bold evolution in mobile technology—seamlessly merging professional-grade hardware with intuitive, integrated AI.

A Professional Imaging System, Re-imagined with AI

The CAMON 50 Ultra 5G is a powerhouse built for visionaries. At its core lies a segment-leading 50MP Sony LYTIA 700C Ultra Night Camera, engineered to achieve exceptional clarity even in the most challenging low-light environments. Complementing this is a dedicated 50MP 3X Telephoto Camera (available on Ultra 5G and Pro models) that brings the iconic 70mm portrait focal length to your fingertips. Whether capturing intimate, flattering close-ups or seizing crisp action from across a stadium with its AI 60X SuperZoom, this flagship system ensures every perspective is rendered with professional-grade precision.

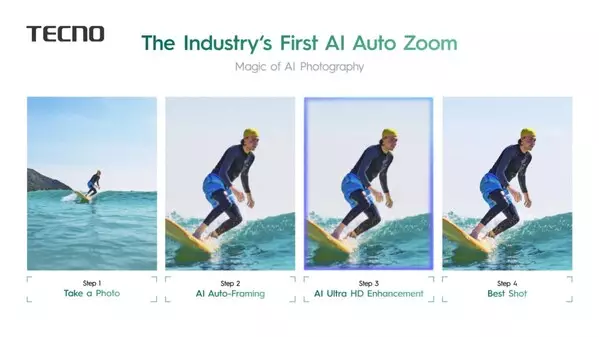

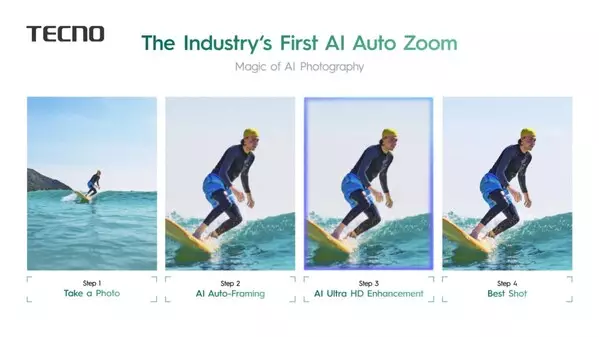

Beyond the lens, the AI RAW 2.0 imaging engine acts as the brain of the CAMON 50 Ultra 5G system, mastering complex light and detail to deliver surgical accuracy and crystalline clarity. The experience is further elevated by Super-Zoom FlashSnap, a breakthrough that seamlessly merges high-speed action capture with powerful telephoto capabilities, allowing users to freeze split-second emotions with perfect precision even from a distance. To perfect the creative process, the industry-first AI Auto Zoom serves as an on-the-go editor, intelligently detecting subjects and cropping for optimal composition into a gallery-ready masterpiece.

Underscoring its exceptional imaging capabilities, the CAMON 50 Ultra 5G achieved an impressive DXOMARK overall camera score of 146—the highest for smartphones under $600—along with a stellar portrait score of 142, ranking among the top in its price segment. "With the upcoming CAMON 50 Ultra 5G, TECNO's proprietary Universal Tone technology confirms a bright and engaging image style that closely matches how users naturally see the scene. Combined, these strengths will make the CAMON 50 Ultra 5G stand out as a compelling choice for accurate and inclusive skin tone rendering under $600," commented Frédérique Guichard, CEO of DXOMARK.

Everyday AI: A Creative and Efficient Partner

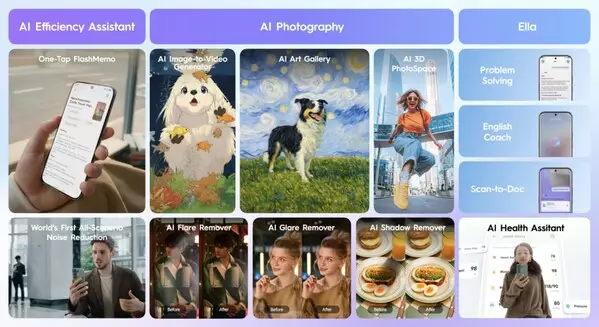

TECNO believes AI should empower your vision, not complicate it. The CAMON 50 Series debuts the industry-first AI Art Gallery, a creative sanctuary where ordinary photos transcend into extraordinary art. Driven by the Dream Scape Model, it offers a global palette of artistic styles, allowing you to reimagine your world through the lens of world-renowned masterpieces or vibrant local heritage. This creative freedom extends beyond the static: the AI Image-to-Video Generator breathes life into still images, while Live Photo captures the heart of every moment and AI 3D PhotoSpace adds immersive spatial depth to ordinary photos.

Even in challenging environments, AI LightMaster 2.0 acts as your invisible lighting crew, vanishing glare, reflections, and distracting shadows with a single tap. Beyond the lens, this intelligence is woven into the fabric of daily life. A dedicated AI Key puts a professional researcher and editor in your pocket; whether you are distilling complex articles with One-Tap FlashMemo, refining social media captions via AI Writing 2.0, or managing wellness via the AI Health Assistant. The upgraded AI assistant, Ella, has evolved into a versatile mentor, serving as your personal Oral Practice Partner and a 24/7 problem-solving tutor.

The CAMON 50 Series also leverages the OneLeap platform to deliver a "silky smooth" experience with TECNO Laptops and MEGAPADs. This interconnected hub facilitates Phone Mirroring, Keyboard and Mouse Sharing, as well as Cross-device Copy and Paste for Text and Image, transforming the series into a high-efficiency workspace.

Engineered for Confidence: Security and Durability Built to Last

The CAMON 50 Series is engineered as a steadfast guardian of your digital life. It marks the debut of TGuard, TECNO's comprehensive security ecosystem. A defining pillar of TGuard is its industry-first off-grid search technology, enabling you to pinpoint your device's location even without a SIM card or when the battery is completely depleted.

The flagship CAMON 50 Ultra 5G delivers reliable performance powered by the MediaTek Dimensity 7400 Ultimate processor. All models in the series feature a 1.5K 144Hz Ultra-bright AMOLED display for ultra-smooth visuals. Durability is paramount, with the series featuring the highest IP68/IP69/IP69K dust and water resistance. This is coupled with a 5-year durability battery of up to 6500mAh (varies by market) and 45W Super Charge. For explorers, the innovative FreeLink technology allows for network-free calling and messaging over Bluetooth Long Range.

"The CAMON 50 Series is designed to be a thoughtful partner in your day," said Jack Guo, General Manager of TECNO. "The AI isn't just for show; it's there to help, whether that's by remembering important information for you, giving your photos a creative twist, or simply making your phone smarter and easier to use. We've focused on making cutting-edge AI feel warm and intuitive, a natural extension of your creativity and your daily life."

For any related media queries, please contact pr.tecno@tecno-mobile.com.

## END ##

About TECNO

As a global innovative technology brand with operations in over 70 markets, TECNO has been committed to revolutionizing the digital experience in global emerging markets, relentlessly pushing for the perfect integration of contemporary, aesthetic design with the latest technologies and AI. TECNO offers a wide range of smartphones, smart wearables, laptops and tablets, smart gaming, HiOS operating systems and smart home products. Guided by its brand essence of "Stop At Nothing", TECNO is committed to unlocking the newest technologies and AI-powered new experiences for forward-looking individuals, inspiring them to never stop pursuing their best selves and their best futures. For more information, please visit TECNO's official site: www.tecno-mobile.com.

The new imaging flagship series fuses advanced hardware with visionary TECNO AI to empower artistic creation, streamline daily life, and safeguard the digital experience.

BARCELONA, Spain, March 4, 2026 /PRNewswire/ -- AI-driven innovative technology brand TECNO today took the stage at MWC 2026 to unveil the CAMON 50 Series. Featuring the CAMON 50 Ultra 5G, CAMON 50 Pro, and CAMON 50, the lineup represents a bold evolution in mobile technology—seamlessly merging professional-grade hardware with intuitive, integrated AI.

A Professional Imaging System, Re-imagined with AI

The CAMON 50 Ultra 5G is a powerhouse built for visionaries. At its core lies a segment-leading 50MP Sony LYTIA 700C Ultra Night Camera, engineered to achieve exceptional clarity even in the most challenging low-light environments. Complementing this is a dedicated 50MP 3X Telephoto Camera (available on Ultra 5G and Pro models) that brings the iconic 70mm portrait focal length to your fingertips. Whether capturing intimate, flattering close-ups or seizing crisp action from across a stadium with its AI 60X SuperZoom, this flagship system ensures every perspective is rendered with professional-grade precision.

Beyond the lens, the AI RAW 2.0 imaging engine acts as the brain of the CAMON 50 Ultra 5G system, mastering complex light and detail to deliver surgical accuracy and crystalline clarity. The experience is further elevated by Super-Zoom FlashSnap, a breakthrough that seamlessly merges high-speed action capture with powerful telephoto capabilities, allowing users to freeze split-second emotions with perfect precision even from a distance. To perfect the creative process, the industry-first AI Auto Zoom serves as an on-the-go editor, intelligently detecting subjects and cropping for optimal composition into a gallery-ready masterpiece.

Underscoring its exceptional imaging capabilities, the CAMON 50 Ultra 5G achieved an impressive DXOMARK overall camera score of 146—the highest for smartphones under $600—along with a stellar portrait score of 142, ranking among the top in its price segment. "With the upcoming CAMON 50 Ultra 5G, TECNO's proprietary Universal Tone technology confirms a bright and engaging image style that closely matches how users naturally see the scene. Combined, these strengths will make the CAMON 50 Ultra 5G stand out as a compelling choice for accurate and inclusive skin tone rendering under $600," commented Frédérique Guichard, CEO of DXOMARK.

Everyday AI: A Creative and Efficient Partner

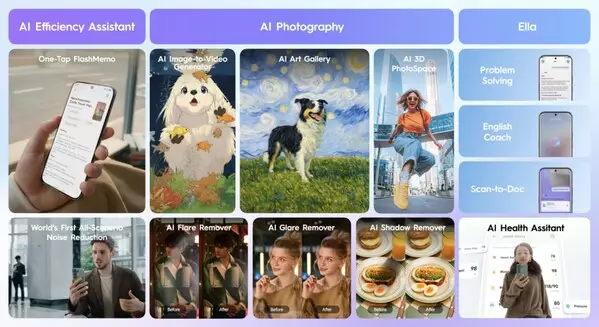

TECNO believes AI should empower your vision, not complicate it. The CAMON 50 Series debuts the industry-first AI Art Gallery, a creative sanctuary where ordinary photos transcend into extraordinary art. Driven by the Dream Scape Model, it offers a global palette of artistic styles, allowing you to reimagine your world through the lens of world-renowned masterpieces or vibrant local heritage. This creative freedom extends beyond the static: the AI Image-to-Video Generator breathes life into still images, while Live Photo captures the heart of every moment and AI 3D PhotoSpace adds immersive spatial depth to ordinary photos.

Even in challenging environments, AI LightMaster 2.0 acts as your invisible lighting crew, vanishing glare, reflections, and distracting shadows with a single tap. Beyond the lens, this intelligence is woven into the fabric of daily life. A dedicated AI Key puts a professional researcher and editor in your pocket; whether you are distilling complex articles with One-Tap FlashMemo, refining social media captions via AI Writing 2.0, or managing wellness via the AI Health Assistant. The upgraded AI assistant, Ella, has evolved into a versatile mentor, serving as your personal Oral Practice Partner and a 24/7 problem-solving tutor.

The CAMON 50 Series also leverages the OneLeap platform to deliver a "silky smooth" experience with TECNO Laptops and MEGAPADs. This interconnected hub facilitates Phone Mirroring, Keyboard and Mouse Sharing, as well as Cross-device Copy and Paste for Text and Image, transforming the series into a high-efficiency workspace.

Engineered for Confidence: Security and Durability Built to Last

The CAMON 50 Series is engineered as a steadfast guardian of your digital life. It marks the debut of TGuard, TECNO's comprehensive security ecosystem. A defining pillar of TGuard is its industry-first off-grid search technology, enabling you to pinpoint your device's location even without a SIM card or when the battery is completely depleted.

The flagship CAMON 50 Ultra 5G delivers reliable performance powered by the MediaTek Dimensity 7400 Ultimate processor. All models in the series feature a 1.5K 144Hz Ultra-bright AMOLED display for ultra-smooth visuals. Durability is paramount, with the series featuring the highest IP68/IP69/IP69K dust and water resistance. This is coupled with a 5-year durability battery of up to 6500mAh (varies by market) and 45W Super Charge. For explorers, the innovative FreeLink technology allows for network-free calling and messaging over Bluetooth Long Range.

"The CAMON 50 Series is designed to be a thoughtful partner in your day," said Jack Guo, General Manager of TECNO. "The AI isn't just for show; it's there to help, whether that's by remembering important information for you, giving your photos a creative twist, or simply making your phone smarter and easier to use. We've focused on making cutting-edge AI feel warm and intuitive, a natural extension of your creativity and your daily life."

For any related media queries, please contact pr.tecno@tecno-mobile.com.

## END ##

About TECNO

As a global innovative technology brand with operations in over 70 markets, TECNO has been committed to revolutionizing the digital experience in global emerging markets, relentlessly pushing for the perfect integration of contemporary, aesthetic design with the latest technologies and AI. TECNO offers a wide range of smartphones, smart wearables, laptops and tablets, smart gaming, HiOS operating systems and smart home products. Guided by its brand essence of "Stop At Nothing", TECNO is committed to unlocking the newest technologies and AI-powered new experiences for forward-looking individuals, inspiring them to never stop pursuing their best selves and their best futures. For more information, please visit TECNO's official site: www.tecno-mobile.com.

** This press release is distributed by PR Newswire through automated distribution system, for which the client assumes full responsibility. **

TECNO CAMON 50 Series: Redefining Professional Imaging Through the Power of Practical AI

TECNO CAMON 50 Series: Redefining Professional Imaging Through the Power of Practical AI

TECNO CAMON 50 Series: Redefining Professional Imaging Through the Power of Practical AI

TECNO CAMON 50 Series: Redefining Professional Imaging Through the Power of Practical AI