|

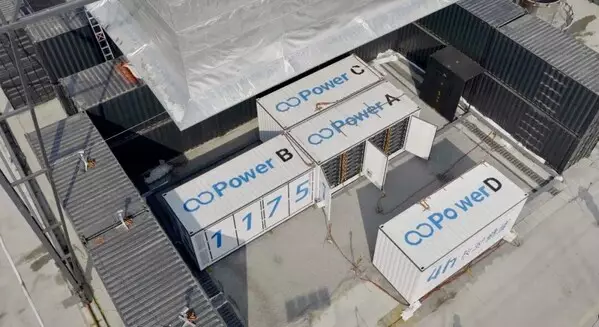

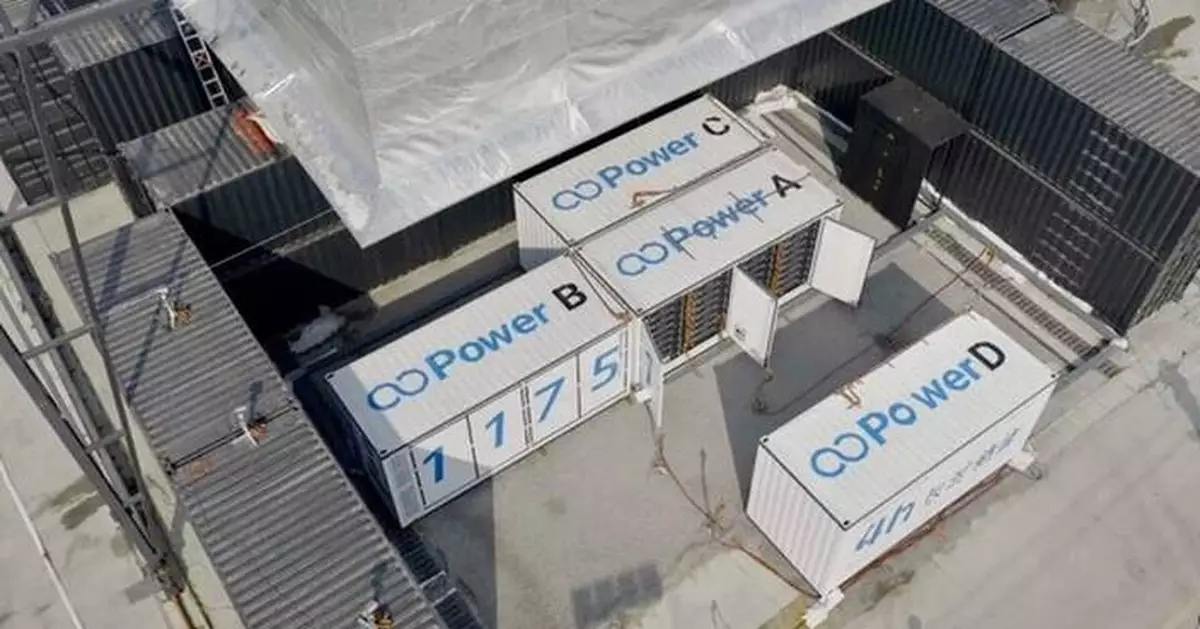

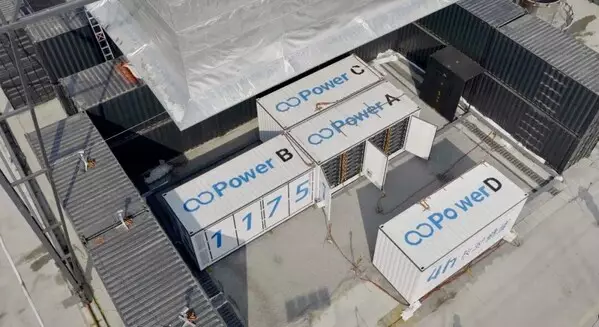

XIAMEN, China, Feb. 9, 2026 /PRNewswire/ -- Recently, HiTHIUM completed the world's first open-door large-scale fire test of its ∞Power 6.25MWh 4h long-duration energy storage (LDES) system equipped with kiloampere-hour (kAh) battery cells. The test was conducted under the full supervision of representatives from UL Solutions, U.S. Authorities Having Jurisdiction, and Fire Protection Engineers. The test strictly complied with the latest requirements of UL 9540A 2025 and NFPA 855-2026.

The test results demonstrate that the high-energy-density 6.25MWh energy storage system, incorporating ultra-large-capacity battery cells, exhibited stable and controllable safety performance under extreme conditions. This marks a critical breakthrough in safety validation at higher energy levels for LDES systems, further strengthening the safety foundation for large-scale industry deployment.

Extreme Real-World Scenarios: Confronting Safety Limits at Higher Energy Levels

Building on its previous open-door fire test of a 5MWh system, HiTHIUM conducted an upgraded validation focusing on the ∞Power 6.25MWh LDES system and its core ∞Cell 1175Ah, verifying system-level safety at significantly higher energy levels.

The test was conducted under the most stringent conditions: the container doors remained fully open throughout the test creating an "open-door combustion" condition to maximize oxygen supply and flame impact; adjacent containers were arranged back-to-back and side-by-side with only 15 cm spacing; the system operated at 100% state of charge; and all active fire suppression systems were disabled, relying solely on intrinsic safety design.

Three Core Safety Challenges: Comprehensive Validation of a Multi-Layer Protection System

To address the compounded risks introduced by ultra-large-capacity cells and high-energy-density systems, HiTHIUM implemented a multi-layer safety architecture spanning the cell, module, and system levels. Guided by the core technical approach of "release, protection, and resistance," the test validated the three core safety challenges.

Release Without Explosion: Precise Management of Ultra-High Energy Release

To manage the massive energy release during thermal runaway of 1175Ah cells, HiTHIUM designed a three-dimensional airflow channel with directional venting, and the module adopted a dual pressure relief valve safety design. This structure enabled rapid and controlled gas release at the cell and module levels, preventing explosive pressure buildup. No explosions or debris ejection were observed during the test.

Combustion Without Propagation: Dual Physical Barriers Against Thermal Spread

Under the most severe conditions of open-door combustion and minimal spacing conditions, the system endured direct flame exposure and intense heat transfer. Fire-resistant module covers, reinforced steel enclosures, and insulated multi-layer container structures confined the fire to a single battery system with no thermal propagation across the containers, and temperatures of cells in adjacent containers remained below safety thresholds.

Resistance Without Structural Failure: Structural Stability Under Extreme Thermal Stress

To withstand prolonged high-temperature exposure, the ∞Power 6.25MWh system was structurally reinforced with a high-strength steel frame, stiffeners, and dual-layer partitions. After continuous combustion, the affected container remained structurally intact, with no significant deformation or collapse observed.

A Milestone Achievement: Redefining Safety Standards for LDES

This test systematically verified the overall safety performance of the ∞Power 6.25MWh LDES system equipped with kAh battery cells, representing a milestone within the global energy storage safety validation framework.

As system capacity continues to increase from 5MWh to 6.25MWh, HiTHIUM remains committed to advancing safety and reliability through rigorous design standards and extreme-condition testing.

Looking ahead, HiTHIUM will remain focused on LDES as a strategic priority, further strengthening its safety foundation and core technologies. By participating in the development of global energy storage safety frameworks to higher standards, and working closely with industry partners, HiTHIUM aims to drive LDES toward larger scale, higher reliability, and safer, more efficient deployment —supporting a steady and sustainable global energy transition.

XIAMEN, China, Feb. 9, 2026 /PRNewswire/ -- Recently, HiTHIUM completed the world's first open-door large-scale fire test of its ∞Power 6.25MWh 4h long-duration energy storage (LDES) system equipped with kiloampere-hour (kAh) battery cells. The test was conducted under the full supervision of representatives from UL Solutions, U.S. Authorities Having Jurisdiction, and Fire Protection Engineers. The test strictly complied with the latest requirements of UL 9540A 2025 and NFPA 855-2026.

The test results demonstrate that the high-energy-density 6.25MWh energy storage system, incorporating ultra-large-capacity battery cells, exhibited stable and controllable safety performance under extreme conditions. This marks a critical breakthrough in safety validation at higher energy levels for LDES systems, further strengthening the safety foundation for large-scale industry deployment.

Extreme Real-World Scenarios: Confronting Safety Limits at Higher Energy Levels

Building on its previous open-door fire test of a 5MWh system, HiTHIUM conducted an upgraded validation focusing on the ∞Power 6.25MWh LDES system and its core ∞Cell 1175Ah, verifying system-level safety at significantly higher energy levels.

The test was conducted under the most stringent conditions: the container doors remained fully open throughout the test creating an "open-door combustion" condition to maximize oxygen supply and flame impact; adjacent containers were arranged back-to-back and side-by-side with only 15 cm spacing; the system operated at 100% state of charge; and all active fire suppression systems were disabled, relying solely on intrinsic safety design.

Three Core Safety Challenges: Comprehensive Validation of a Multi-Layer Protection System

To address the compounded risks introduced by ultra-large-capacity cells and high-energy-density systems, HiTHIUM implemented a multi-layer safety architecture spanning the cell, module, and system levels. Guided by the core technical approach of "release, protection, and resistance," the test validated the three core safety challenges.

Release Without Explosion: Precise Management of Ultra-High Energy Release

To manage the massive energy release during thermal runaway of 1175Ah cells, HiTHIUM designed a three-dimensional airflow channel with directional venting, and the module adopted a dual pressure relief valve safety design. This structure enabled rapid and controlled gas release at the cell and module levels, preventing explosive pressure buildup. No explosions or debris ejection were observed during the test.

Combustion Without Propagation: Dual Physical Barriers Against Thermal Spread

Under the most severe conditions of open-door combustion and minimal spacing conditions, the system endured direct flame exposure and intense heat transfer. Fire-resistant module covers, reinforced steel enclosures, and insulated multi-layer container structures confined the fire to a single battery system with no thermal propagation across the containers, and temperatures of cells in adjacent containers remained below safety thresholds.

Resistance Without Structural Failure: Structural Stability Under Extreme Thermal Stress

To withstand prolonged high-temperature exposure, the ∞Power 6.25MWh system was structurally reinforced with a high-strength steel frame, stiffeners, and dual-layer partitions. After continuous combustion, the affected container remained structurally intact, with no significant deformation or collapse observed.

A Milestone Achievement: Redefining Safety Standards for LDES

This test systematically verified the overall safety performance of the ∞Power 6.25MWh LDES system equipped with kAh battery cells, representing a milestone within the global energy storage safety validation framework.

As system capacity continues to increase from 5MWh to 6.25MWh, HiTHIUM remains committed to advancing safety and reliability through rigorous design standards and extreme-condition testing.

Looking ahead, HiTHIUM will remain focused on LDES as a strategic priority, further strengthening its safety foundation and core technologies. By participating in the development of global energy storage safety frameworks to higher standards, and working closely with industry partners, HiTHIUM aims to drive LDES toward larger scale, higher reliability, and safer, more efficient deployment —supporting a steady and sustainable global energy transition.

** The press release content is from PR Newswire. Bastille Post is not involved in its creation. **

HiTHIUM Completes World's First Open-Door Large-Scale Fire Test of a 6.25MWh BESS with kAh Battery Cells

|

New facility delivers 24/7 threat monitoring, rapid response and AI-driven cybersecurity for industrial operations across Asia Pacific.

SINGAPORE, Feb. 9, 2026 /PRNewswire/ -- Rockwell Automation, the world's largest company dedicated to industrial automation and digital transformation, has launched a Security Operations Center (SOC) in Singapore, enhancing cybersecurity resilience for industrial customers across Asia Pacific.

The new facility is part of Rockwell Automation's global network of Managed Security Services and delivers 24/7 real-time monitoring, advanced threat detection and rapid incident response through its SecureOT™ Security Monitoring and Response capabilities. Designed to address the growing convergence of IT and OT environments, the SOC helps industrial companies detect, respond to and recover from cybersecurity incidents faster and more effectively.

Located within Rockwell's Asia Pacific headquarters in Singapore, the SOC serves as a regional hub for Managed Detection and Response (MDR) services. It integrates vendor-neutral data ingestion, contextualized threat intelligence, and risk-based prioritization, enabling industrial teams to focus on the most critical vulnerabilities across complex, multi-vendor environments while ensuring rapid response and step-by-step remediation guided by Rockwell's cybersecurity experts.

"Cybersecurity is now inseparable from digital transformation," said Marcelo Tarkieltaub, regional director, Southeast Asia, Rockwell Automation. "Our new regional SOC hub in Singapore reflects our commitment to helping manufacturers connect, automate and protect their operations end-to-end. Having multiple capabilities under one roof allows for deeper collaboration and faster response, delivering stronger protection for our customers' critical operations. It enables them to test and engage with our capabilities firsthand, an important step for organizations evaluating the right partners for their cybersecurity journey."

"The opening of our regional SOC reinforces Singapore's role as a cybersecurity hub for the region. We look forward to deepening our collaboration with local agencies, academia and partners to strengthen industrial resilience and upskill new cybersecurity talent. In fact, we've recently onboarded several young professionals with cybersecurity majors, building their expertise to support global clients in the industrial security space."

Companies in the region face growing threats such as data theft, extortion, and ransomware, in part due to Asia Pacific's critical role in global supply chains and its position as a technology and manufacturing hub. Rockwell Automation's 10th Annual 2025 State of Smart Manufacturing Report found that cybersecurity has risen to the second most critical external risk for manufacturers in Asia Pacific, with nearly half of respondents planning to deploy AI and machine learning for cybersecurity use cases within the next year.

Rockwell Automation's SOC leverages Security Orchestration, Automation and Response (SOAR), a technology platform that combines automation, AI and analytics to streamline and accelerate responses to cyber threats. This enables Rockwell's Managed Detection and Response services to offer customers a single pane of glass view of cyber incidents and actions across multiple sites, as some global manufacturers need to monitor more than 100 locations.

Aligned with Singapore's national ambition to build a secure digital economy, the facility complements Rockwell's collaboration with the Cyber Security Agency of Singapore (CSA) and industry partners to advance industrial cybersecurity maturity across the region. It will also host training workshops and customer simulations, giving participants hands-on exposure to real-world OT threat scenarios.

The new SOC builds on Rockwell's SecureOT™ Solution Suite, which encompasses Strategic Advisory, Managed Industrial Networking and Infrastructure, Asset Management, Risk and Vulnerability Management, and Incident Response services.

About Rockwell Automation

Rockwell Automation, Inc. (NYSE: ROK), is a global leader in industrial automation and digital transformation. We connect the imaginations of people with the potential of technology to expand what is humanly possible, making the world more productive and more sustainable. Headquartered in Milwaukee, Wisconsin, Rockwell Automation employs approximately 26,000 problem solvers dedicated to our customers in more than 100 countries as of fiscal year end 2025. To learn more about how we are bringing the Connected Enterprise to life across industrial enterprises, visit www.rockwellautomation.com.

New facility delivers 24/7 threat monitoring, rapid response and AI-driven cybersecurity for industrial operations across Asia Pacific.

SINGAPORE, Feb. 9, 2026 /PRNewswire/ -- Rockwell Automation, the world's largest company dedicated to industrial automation and digital transformation, has launched a Security Operations Center (SOC) in Singapore, enhancing cybersecurity resilience for industrial customers across Asia Pacific.

The new facility is part of Rockwell Automation's global network of Managed Security Services and delivers 24/7 real-time monitoring, advanced threat detection and rapid incident response through its SecureOT™ Security Monitoring and Response capabilities. Designed to address the growing convergence of IT and OT environments, the SOC helps industrial companies detect, respond to and recover from cybersecurity incidents faster and more effectively.

Located within Rockwell's Asia Pacific headquarters in Singapore, the SOC serves as a regional hub for Managed Detection and Response (MDR) services. It integrates vendor-neutral data ingestion, contextualized threat intelligence, and risk-based prioritization, enabling industrial teams to focus on the most critical vulnerabilities across complex, multi-vendor environments while ensuring rapid response and step-by-step remediation guided by Rockwell's cybersecurity experts.

"Cybersecurity is now inseparable from digital transformation," said Marcelo Tarkieltaub, regional director, Southeast Asia, Rockwell Automation. "Our new regional SOC hub in Singapore reflects our commitment to helping manufacturers connect, automate and protect their operations end-to-end. Having multiple capabilities under one roof allows for deeper collaboration and faster response, delivering stronger protection for our customers' critical operations. It enables them to test and engage with our capabilities firsthand, an important step for organizations evaluating the right partners for their cybersecurity journey."

"The opening of our regional SOC reinforces Singapore's role as a cybersecurity hub for the region. We look forward to deepening our collaboration with local agencies, academia and partners to strengthen industrial resilience and upskill new cybersecurity talent. In fact, we've recently onboarded several young professionals with cybersecurity majors, building their expertise to support global clients in the industrial security space."

Companies in the region face growing threats such as data theft, extortion, and ransomware, in part due to Asia Pacific's critical role in global supply chains and its position as a technology and manufacturing hub. Rockwell Automation's 10th Annual 2025 State of Smart Manufacturing Report found that cybersecurity has risen to the second most critical external risk for manufacturers in Asia Pacific, with nearly half of respondents planning to deploy AI and machine learning for cybersecurity use cases within the next year.

Rockwell Automation's SOC leverages Security Orchestration, Automation and Response (SOAR), a technology platform that combines automation, AI and analytics to streamline and accelerate responses to cyber threats. This enables Rockwell's Managed Detection and Response services to offer customers a single pane of glass view of cyber incidents and actions across multiple sites, as some global manufacturers need to monitor more than 100 locations.

Aligned with Singapore's national ambition to build a secure digital economy, the facility complements Rockwell's collaboration with the Cyber Security Agency of Singapore (CSA) and industry partners to advance industrial cybersecurity maturity across the region. It will also host training workshops and customer simulations, giving participants hands-on exposure to real-world OT threat scenarios.

The new SOC builds on Rockwell's SecureOT™ Solution Suite, which encompasses Strategic Advisory, Managed Industrial Networking and Infrastructure, Asset Management, Risk and Vulnerability Management, and Incident Response services.

About Rockwell Automation

Rockwell Automation, Inc. (NYSE: ROK), is a global leader in industrial automation and digital transformation. We connect the imaginations of people with the potential of technology to expand what is humanly possible, making the world more productive and more sustainable. Headquartered in Milwaukee, Wisconsin, Rockwell Automation employs approximately 26,000 problem solvers dedicated to our customers in more than 100 countries as of fiscal year end 2025. To learn more about how we are bringing the Connected Enterprise to life across industrial enterprises, visit www.rockwellautomation.com.

** The press release content is from PR Newswire. Bastille Post is not involved in its creation. **

Rockwell Automation Strengthens Industrial Cybersecurity with New Security Operations Center in Singapore