|

- Collaboration with impact – Turning partnerships into regional innovation for Singapore's next phase of growth

- Innovating for tomorrow – Developing next-gen adhesive solutions that meet future industry needs

- Building sustainable progress – Advancing circular economy and more sustainable processes across industries

SINGAPORE, Feb. 10, 2026 /PRNewswire/ -- tesa, an international manufacturer of innovative adhesive tapes and self-adhesive product solutions, celebrates its 45th anniversary in Singapore this year, marking more than four decades of longstanding commitment and partnership in supporting the nation's industrial development, skills transformation and sustainability journey.

Since establishing its presence in Singapore in 1981, tesa has grown alongside the country's transformation into a global hub for business, manufacturing and advanced technologies. Over the last 45 years, tesa has played a pivotal role in enabling precision manufacturing, supporting critical industries and fostering talent development across the Asia-Pacific region through Singapore.

A key partner in Singapore's industrial and manufacturing growth

Backed by over 125 years of experience in the development and manufacture of adhesives and in coating technology, tesa supports advanced manufacturing across multiple industries. Today, tesa's adhesive and bonding technologies are embedded in products that power life, from smartphones and automotive vehicles to industrial automation systems and packaging.

"Singapore has become a strategic partner in our growth across Asia-Pacific. Over the past 45 years, we have grown together with Singapore's industrial ecosystem and contributed to nation building through technology, knowledge transfer and long-term partnerships," said Andreas Gunnestrand, President and Regional Manager, tesa tape Asia-Pacific.

Driving innovation and collaboration across the region through Singapore

Innovation and collaboration are central to tesa's global success, with Singapore serving as the Asia-Pacific centre of operational best practices across regional offices in Vietnam, Thailand and India, and supporting the development of advanced technologies across key markets.

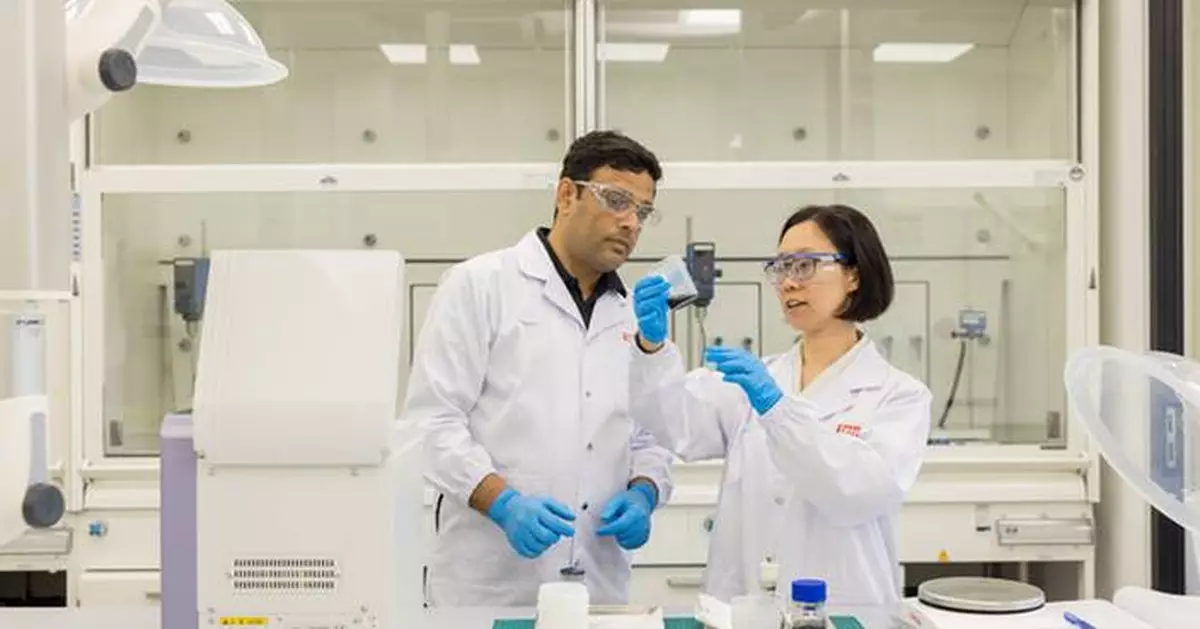

Initiatives such as tesa's new state-of-the-art Debonding on Demand laboratory, opened in partnership with A*STAR, underscore the company's commitment to accelerating the development of market-ready adhesive solutions, while further strengthening Singapore's position as a hub for advanced manufacturing and circular economy innovation. tesa's Debonding on Demand technologies enable clean, damage-free separation which allows manufacturers to disassemble and rework components quickly and efficiently to reduce downtime and maintain cost-effectiveness, while supporting compliance with evolving repair and recycling targets.

In addition, tesa Singapore supports regional customers with technical consulting, customised applications and rapid prototyping capabilities, which helps accelerate product development cycles and improve manufacturing efficiency.

Advancing sustainability and responsible growth

Sustainability is a central pillar of tesa's global strategy, with Singapore playing an instrumental role in advancing the company's environmental commitments in the region.

In alignment with the Singapore Green Plan 2030 and broader regional decarbonisation efforts, tesa is focused on reducing emissions, improving resource efficiency and has introduced more sustainable adhesive solutions, including solvent-reduced technologies, bio-based materials and recyclable product designs, to help support customers in achieving their own sustainability goals.

Continuous development into the future

As Singapore enters its next phase of smart manufacturing, electrification and digitalisation, adhesive technologies are playing an increasingly central role in industrial innovation, supporting greater efficiency, performance, and sustainability across industries.

"45 years is both a milestone and a moment of reflection," said Gunnestrand. "Singapore will continue to serve as a strategic gateway for tesa's Asia-Pacific growth, supporting key markets across the region and beyond. We are proud of the role we have played in Singapore's journey, and we remain committed to contributing to the nation's next phase of growth through innovation, talent development and sustainable progress."

About tesa SE

As a multinational company, tesa develops innovative adhesive tapes and self-adhesive product solutions for various industries, commercial customers, and end consumers for more than 125 years. There are already more than 7,000 tesa adhesive solutions that help improve the work, products or lives of our customers. Today, the focus is on sustainability and energy-saving processes. tesa invests in the development of environmentally friendly products and solvent-free manufacture processes as well as in the use of renewable energy sources at its locations.

tesa is active in 100 countries and operates plants in Germany, Italy, China, the USA, and in Vietnam. Around three quarters of the tesa Group's sales (2024: EUR 1.7 billion euro) are generated by applications for industries. Together with its international clients, tesa develops innovations that are customized at product and process level. Already more than 130 tesa tapes may be installed in an electric car and over 70 in a smartphone. In the printing and construction industries, too, tesa is constantly penetrating new segments and countries with its special adhesive tapes. The company generates almost one quarter of its sales with products for end consumers and professional craftsmen. 300 applications, such as the legendary tesafilm®, make life easier or, when it comes to insect protection, even make it a bit more pleasant. tesa counts among the world's leading manufacturers of adhesive solutions. Since 2001, tesa SE is an independent 100% affiliate of Beiersdorf AG (i.e., NIVEA, Eucerin, la prairie) with approx. 5,400 employees today.

- Collaboration with impact – Turning partnerships into regional innovation for Singapore's next phase of growth

- Innovating for tomorrow – Developing next-gen adhesive solutions that meet future industry needs

- Building sustainable progress – Advancing circular economy and more sustainable processes across industries

SINGAPORE, Feb. 10, 2026 /PRNewswire/ -- tesa, an international manufacturer of innovative adhesive tapes and self-adhesive product solutions, celebrates its 45th anniversary in Singapore this year, marking more than four decades of longstanding commitment and partnership in supporting the nation's industrial development, skills transformation and sustainability journey.

Since establishing its presence in Singapore in 1981, tesa has grown alongside the country's transformation into a global hub for business, manufacturing and advanced technologies. Over the last 45 years, tesa has played a pivotal role in enabling precision manufacturing, supporting critical industries and fostering talent development across the Asia-Pacific region through Singapore.

A key partner in Singapore's industrial and manufacturing growth

Backed by over 125 years of experience in the development and manufacture of adhesives and in coating technology, tesa supports advanced manufacturing across multiple industries. Today, tesa's adhesive and bonding technologies are embedded in products that power life, from smartphones and automotive vehicles to industrial automation systems and packaging.

"Singapore has become a strategic partner in our growth across Asia-Pacific. Over the past 45 years, we have grown together with Singapore's industrial ecosystem and contributed to nation building through technology, knowledge transfer and long-term partnerships," said Andreas Gunnestrand, President and Regional Manager, tesa tape Asia-Pacific.

Driving innovation and collaboration across the region through Singapore

Innovation and collaboration are central to tesa's global success, with Singapore serving as the Asia-Pacific centre of operational best practices across regional offices in Vietnam, Thailand and India, and supporting the development of advanced technologies across key markets.

Initiatives such as tesa's new state-of-the-art Debonding on Demand laboratory, opened in partnership with A*STAR, underscore the company's commitment to accelerating the development of market-ready adhesive solutions, while further strengthening Singapore's position as a hub for advanced manufacturing and circular economy innovation. tesa's Debonding on Demand technologies enable clean, damage-free separation which allows manufacturers to disassemble and rework components quickly and efficiently to reduce downtime and maintain cost-effectiveness, while supporting compliance with evolving repair and recycling targets.

In addition, tesa Singapore supports regional customers with technical consulting, customised applications and rapid prototyping capabilities, which helps accelerate product development cycles and improve manufacturing efficiency.

Advancing sustainability and responsible growth

Sustainability is a central pillar of tesa's global strategy, with Singapore playing an instrumental role in advancing the company's environmental commitments in the region.

In alignment with the Singapore Green Plan 2030 and broader regional decarbonisation efforts, tesa is focused on reducing emissions, improving resource efficiency and has introduced more sustainable adhesive solutions, including solvent-reduced technologies, bio-based materials and recyclable product designs, to help support customers in achieving their own sustainability goals.

Continuous development into the future

As Singapore enters its next phase of smart manufacturing, electrification and digitalisation, adhesive technologies are playing an increasingly central role in industrial innovation, supporting greater efficiency, performance, and sustainability across industries.

"45 years is both a milestone and a moment of reflection," said Gunnestrand. "Singapore will continue to serve as a strategic gateway for tesa's Asia-Pacific growth, supporting key markets across the region and beyond. We are proud of the role we have played in Singapore's journey, and we remain committed to contributing to the nation's next phase of growth through innovation, talent development and sustainable progress."

About tesa SE

As a multinational company, tesa develops innovative adhesive tapes and self-adhesive product solutions for various industries, commercial customers, and end consumers for more than 125 years. There are already more than 7,000 tesa adhesive solutions that help improve the work, products or lives of our customers. Today, the focus is on sustainability and energy-saving processes. tesa invests in the development of environmentally friendly products and solvent-free manufacture processes as well as in the use of renewable energy sources at its locations.

tesa is active in 100 countries and operates plants in Germany, Italy, China, the USA, and in Vietnam. Around three quarters of the tesa Group's sales (2024: EUR 1.7 billion euro) are generated by applications for industries. Together with its international clients, tesa develops innovations that are customized at product and process level. Already more than 130 tesa tapes may be installed in an electric car and over 70 in a smartphone. In the printing and construction industries, too, tesa is constantly penetrating new segments and countries with its special adhesive tapes. The company generates almost one quarter of its sales with products for end consumers and professional craftsmen. 300 applications, such as the legendary tesafilm®, make life easier or, when it comes to insect protection, even make it a bit more pleasant. tesa counts among the world's leading manufacturers of adhesive solutions. Since 2001, tesa SE is an independent 100% affiliate of Beiersdorf AG (i.e., NIVEA, Eucerin, la prairie) with approx. 5,400 employees today.

** The press release content is from PR Newswire. Bastille Post is not involved in its creation. **

A 45-year bond: tesa drives innovation and sustainable growth in Singapore

BANGKOK, Feb. 10, 2026 /PRNewswire/ -- Researchers at Chulalongkorn University are redefining the role of Thai silk by developing silk protein into a versatile platform for medical products, aiming to reduce Thailand's reliance on imported biomaterials while creating sustainable income for farmers.

The Silklife research project, led by Associate Professor Dr. Juthamas Ratanavaraporn of the Faculty of Engineering, converts silk protein into various medical applications, including pain-relief and sleep-aid patches, artificial tissues, and injectable joint gels. The initiative addresses a key challenge facing Thailand's rapidly expanding medical industry, which still depends heavily on imported materials such as collagen and hyaluronic acid.

Thai silk, traditionally valued as a cultural heritage textile, possesses unique biomedical properties. Its primary protein, fibroin, is naturally strong, biocompatible, and safely degrades into amino acids in the body. Unlike silk from other countries, Thai silk has a natural golden hue and a hydrophobic molecular structure, enabling it to bind effectively with certain drug compounds and making it suitable for targeted drug delivery systems.

The Silklife project adopts a comprehensive approach spanning the entire value chain. The research team established an organic silkworm farming model on five rai of land in Ratchaburi province, certified under Thailand's organic agriculture standards. Controlled, closed-system rearing facilities—certified under Thai Agricultural Standard 8203—ensure consistent quality year-round. Contract farmers are trained to follow strict operating procedures to minimize contamination.

High-quality cocoons are processed at a pilot plant meeting ISO 13485 manufacturing standards and ISO 10993 medical safety standards. Achieving medical-grade silk protein requires three to four years of development from upstream farming to midstream processing.

Initial products focus on external use to build safety and market confidence, including hydrogel skin patches that release herbal pain-relief compounds for up to eight hours, and CBD sleep patches designed as an alternative to high-dose oral administration. More advanced applications include biodegradable scaffolds for dental and tissue regeneration and injectable silk-based joint gels now entering early-stage clinical trials at King Chulalongkorn Memorial Hospital.

Beyond medical innovation, the project delivers economic impact. Participating farmers can sell medical-grade silk cocoons at prices several times higher than conventional market rates. Researchers emphasize that Silklife's platform approach allows a single material to be developed into dozens of products, positioning Thai silk as a competitive, homegrown alternative in global medical markets.

For more information, visit www.enginelife.co.th

Read the full article at: https://www.chula.ac.th/en/highlight/285235/

About Chulalongkorn University

Chulalongkorn University has made the world's top 50 university list for employment outcomes, which reflects both the high employment rate and work ability of Chula graduates. The university is also listed as the best in Thailand for the 15th Consecutive Year (since 2009), according to the newly released QS World University Rankings 2024, putting Chula at 211th in the world, up from 244th last year.

Social Media:

Facebook: https://www.facebook.com/ChulalongkornUniversity

Youtube: https://www.youtube.com/chulauniversity

Linkedin: https://www.linkedin.com/school/15101896/

** The press release content is from PR Newswire. Bastille Post is not involved in its creation. **

Silklife: Chula Researchers Transform Thai Silk into Medical Innovation