Feature · News

Reform, innovation, people's livelihood key themes of gov't work report: official

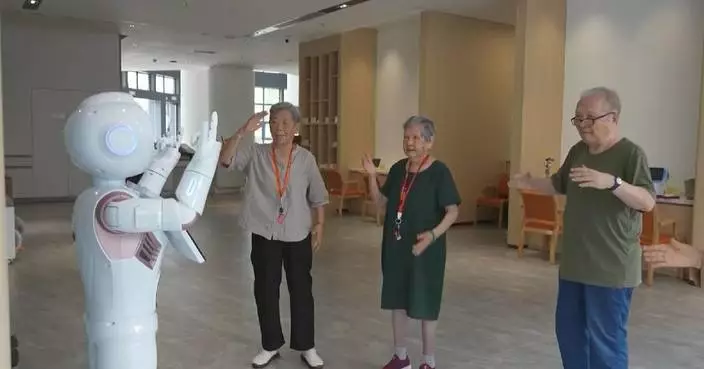

China advances healthcare, childcare, elderly care services in past five years

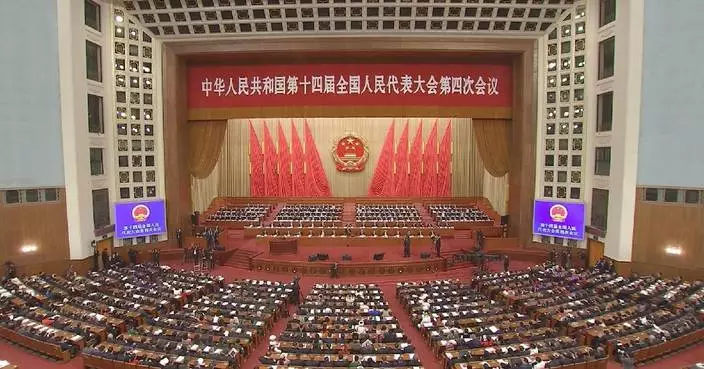

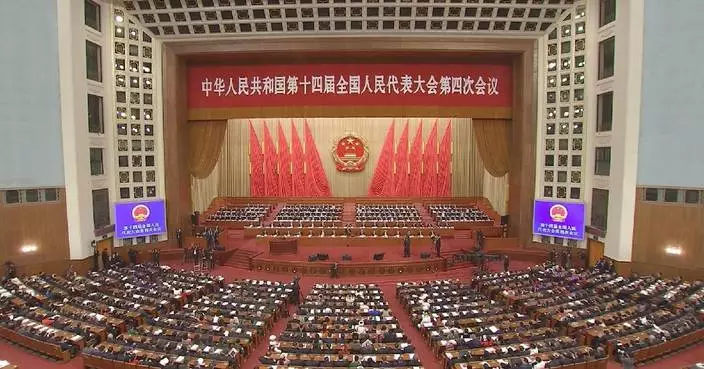

China's national legislature opens annual session

China to subsidize vocational training for over 10 million people in 2026

China's new development plan to fuel green tech growth in Global South: officials

China to continue adopting more proactive fiscal policy, appropriately accommodative monetary policy in 2026

China to step up efforts to improve people's well-being during 15th Five-Year Plan: official

China opposes military strikes against Iran by Israel, US, urges immediate halt of military actions: FM spokeswoman

China's National Legislature Opens Annual Session with 15th Five-Year Plan Draft Outlined; Expert Says Long-term Planning Brings Stability and Highlights Institutional Strengths

China to strengthen fiscal, financial coordination to amplify policy effectiveness: experts

Florida Bar walks back statement on investigation into Halligan, now says there is none

Iranian attacks target Gulf States as US warns bombing will intensify

People pay their respects to the late Rev. Jesse Jackson, in photos

Trump wants "unconditional surrender," attacks on Tehran continue

Explosion at Dubai airport prompts emergency passenger evacuation

Police Have Arrested Three Workers in the Wang Fuk Court Reinforcement Project for Suspected Theft

China to step up efforts to improve people's well-being during 15th Five-Year Plan: official

China opposes military strikes against Iran by Israel, US, urges immediate halt of military actions: FM spokeswoman

China's National Legislature Opens Annual Session with 15th Five-Year Plan Draft Outlined; Expert Says Long-term Planning Brings Stability and Highlights Institutional Strengths

China to strengthen fiscal, financial coordination to amplify policy effectiveness: experts

Reform, innovation, people's livelihood key themes of gov't work report: official

China advances healthcare, childcare, elderly care services in past five years

China's national legislature opens annual session

China to subsidize vocational training for over 10 million people in 2026

China's new development plan to fuel green tech growth in Global South: officials

China to continue adopting more proactive fiscal policy, appropriately accommodative monetary policy in 2026

Florida Bar walks back statement on investigation into Halligan, now says there is none

Iranian attacks target Gulf States as US warns bombing will intensify

People pay their respects to the late Rev. Jesse Jackson, in photos

Trump wants "unconditional surrender," attacks on Tehran continue

Explosion at Dubai airport prompts emergency passenger evacuation

Police Have Arrested Three Workers in the Wang Fuk Court Reinforcement Project for Suspected Theft

Feature·Bloggers

Oil and gas prices rapidly rise as Iran war shows no signs of letting up

- The Latest: Trump says he’ll hit Iran harder as Iranian president apologizes to neighbors

- Trump encourages Latin American leaders to use military action to help US fight cartels

- At least 25 dead in Kenya after heavy rain brings flash floods and flight disruption to Nairobi

- What to know: Downtown Anchorage braces for a canine takeover as the Iditarod’s 54th run begins

- Cuba says crews repaired a large power plant that caused a massive outage

- Dozens killed in Lebanon as Israel searches for signs of navigator missing for 40 years

- Ian Huntley, one of UK's most notorious child killers, has died, days after being attacked in prison

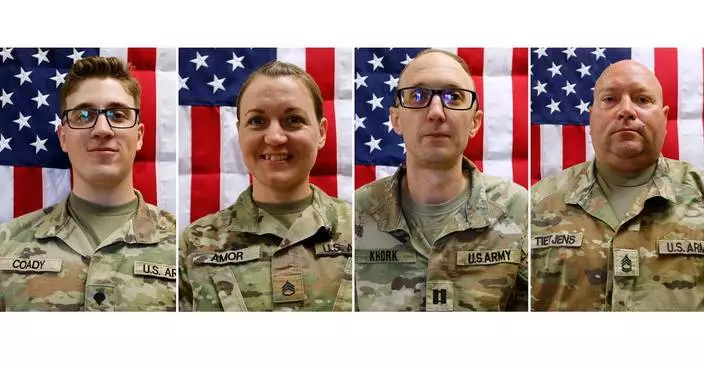

- Trump will join grieving families for the return of soldiers killed in war in the Middle East

- Tornadoes kill 6 people in Michigan and Oklahoma as powerful storms hit nation's midsection

China's opening-up should continue path of inclusiveness: political advisor

- China's top political advisory body holds 2nd plenary meeting of annual session

- CPPCC member on healthcare transformation in Xizang

- China to step up efforts to ensure, improve people's wellbeing in next five years

- National political advisor on closer academia-industry collaboration

- NPC deputies share Xinjiang's development feat at group meeting

- Innovation experts from across China highlight accelerated tech deployment

- AI trained to play video games in stepping stone to real world applications

- Innovation drives transformation of manufacturing industry: CPPCC member

- China leads world in plateau medicine research-development, application: CPPCC member

Visitors become entrepreneurs, discover opportunities in Yunnan

- Ukraine’s low-cost Shahed killers draw US and Gulf interest, but a wartime ban blocks sales

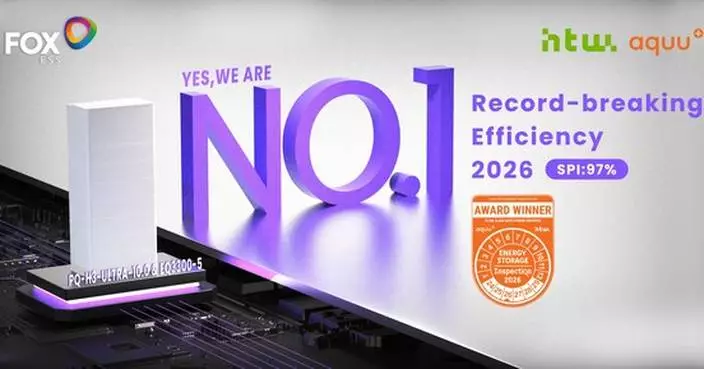

- Fox ESS Achieves Record 97% Energy Storage Efficiency under HTW Rankings

- LGMG Showcases New Products and Service Initiatives at CONEXPO-CON/AGG 2026

- GAC Chairman Highlights "Standards Going Global" to Drive High-Quality Overseas Expansion

- MIFF 2026 AWARDS HONOUR DESIGN EXCELLENCE IN THE FURNITURE INDUSTRY

- Bybit Announces Departure of Co-CEO Helen Liu as She Embarks on Entrepreneurial Journey

- UGREEN Appoints Iqbaal Ramadhan as Brand Ambassador, Inspiring Indonesia to "Activate Your Beat"

- Saks Global to shutter 15 more department stores in bankruptcy restructuring

- Oil surges to its highest price since 2023, and stocks drop after a weak update on the US job market

Families with missing loved ones like Nancy Guthrie face ambiguous loss. It freezes grief

- Pentagon's chief tech officer says he clashed with AI company Anthropic over autonomous warfare

- Heat waves that spark damaging droughts are happening more frequently, study finds

- Spacecraft's impact changed asteroid's orbit around the sun in a save-the-Earth test, study finds

- Jarring alarms out, quieter alerts in. New firehouse dispatch systems aim to ease stress

- Indonesia to ban social media for children under 16, communication minister says

- Pentagon says it is labeling AI company Anthropic a supply chain risk 'effective immediately'

- Elon Musk defends tweets in lawsuit alleging they caused Twitter stock to fall before acquisition

- No chance asteroid will slam into the moon in 2032, NASA says

- New Mexico jurors watch Zuckerberg deposition in Meta child safety bellwether trial

Woman sues author Amy Griffin, saying her memoir 'The Tell' stole stories of sexual abuse

- Spanish soccer team desperately seeking Madonna and her 36-year-old shirt

- J Balvin remade Van Halen's 'Jump' as Coca-Cola's World Cup anthem. He says it was 'a puzzle'

- Andris Nelsons out as music director of Boston Symphony at end of 2026-27 season

- Kennedy Center exodus continues as National Symphony director Jean Davidson heads to the Wallis

- After 5 years, Sarah J. Maas returns to 'A Court of Thorns and Roses' with 2 untitled books

- In Paris fashion, skin is in and celebrities rule the runways

- Daryl Hannah issues scathing response to portrayal of her on TV series about Kennedy and Bessette

- Oprah and Gayle King hobnob at Chloe's boho blouse-focused Paris fashion show

- A Lagos rave rewrites the rules of nightlife, drawing young Nigerians priced out of club culture

Scotland stuns France 50-40 and blows open the Six Nations title race

- Coach Luis Enrique now accepts PSG is out of form after weeks of defending his players

- Bayern goalkeeper Manuel Neuer out with another calf injury on comeback

- Arsenal advances to FA Cup quarterfinals with 2-1 win over third-tier Mansfield

- Para alpine skiers Voronchikhina and Bugaev give Russia its first Paralympic medals in 12 years

- Lindsey Vonn loses lead in World Cup downhill standings as Laura Pirovano wins by 0.01 again

- Olympic champion Pinheiro Braathen wins World Cup giant slalom with Odermatt fifth

- Lando Norris says F1 cars gone from best to 'probably the worst'

- Max Verstappen gets X-rays on hands after crash at Australian GP qualifying

- NFL teams are becoming more willing to trade two first-round picks for elite defensive players

Hong Kong Police Launches Fifth Cohort of L.I.O.N. to Nurture Young Anti-Drug Leaders

- Two Passengers Sentenced for Smuggling Duty-Not-Paid Cigarettes in Hong Kong Airport.

- Man Sentenced to Six Months for Illegally Importing Tobacco Products into Hong Kong.

- Health Authorities Investigate Gastroenteritis Cluster at Wong Chuk Hang Training Institute

- DoJ Honors 40 ROLE Ambassadors at Ceremony Promoting Rule of Law Education in Hong Kong

- Students Create Stunning Floral Display for Hong Kong Flower Show at Victoria Park

- Jimmy Lai Case | Colludes with Foreign Forces and Sentenced to 20 Years, Local Legal Team Confirms Lai Not to Appeal

- Bastille's Story: Taste of Taiwan - The Secret Recipe for a Takeaway Shop's Success in HK

- HKETO Berlin Celebrates Year of the Horse with Receptions in Slovenia and Switzerland

- Couple Sentenced for Dealing Duty-Not-Paid Cigarettes in Hong Kong Courts

China to deepen people-centered medical reform: official

- Review: China’s space development over past five years

- Long March-8A carrier rocket transferred to launch pad

- China strives to build "childcare-friendly society" to address declining birth rate

- Rocket manufacturing capability should further improve to meet China's growing aerospace demands: CPPCC member

- Global observers hail China's high-quality development

- Chinese political advisor stresses exchanges among different civilizations in CPPCC interview

- China's domestic travel hits record highs in 2025: official

- Iran to halt strikes on neighbors unless attacked: President

- Professor advocates science popularization to inspire future innovators at CPPCC session

Category · News

Scotland stuns France 50-40 and blows open the Six Nations title race

Oil and gas prices rapidly rise as Iran war shows no signs of letting up

The Latest: Trump says he’ll hit Iran harder as Iranian president apologizes to neighbors

Trump encourages Latin American leaders to use military action to help US fight cartels

Coach Luis Enrique now accepts PSG is out of form after weeks of defending his players

At least 25 dead in Kenya after heavy rain brings flash floods and flight disruption to Nairobi

What to know: Downtown Anchorage braces for a canine takeover as the Iditarod’s 54th run begins

Cuba says crews repaired a large power plant that caused a massive outage

Dozens killed in Lebanon as Israel searches for signs of navigator missing for 40 years

Bayern goalkeeper Manuel Neuer out with another calf injury on comeback

Ian Huntley, one of UK's most notorious child killers, has died, days after being attacked in prison

Arsenal advances to FA Cup quarterfinals with 2-1 win over third-tier Mansfield

Para alpine skiers Voronchikhina and Bugaev give Russia its first Paralympic medals in 12 years

Trump will join grieving families for the return of soldiers killed in war in the Middle East

Tornadoes kill 6 people in Michigan and Oklahoma as powerful storms hit nation's midsection

China's opening-up should continue path of inclusiveness: political advisor

China's top political advisory body holds 2nd plenary meeting of annual session

CPPCC member on healthcare transformation in Xizang

China to step up efforts to ensure, improve people's wellbeing in next five years

National political advisor on closer academia-industry collaboration

Families with missing loved ones like Nancy Guthrie face ambiguous loss. It freezes grief

NPC deputies share Xinjiang's development feat at group meeting

Innovation experts from across China highlight accelerated tech deployment

Iran war deaths could resurface Trump’s complicated history with military sacrifice

Ex-rapper's political party leads early results in Nepal's first election since 2025 youth revolt

Lindsey Vonn loses lead in World Cup downhill standings as Laura Pirovano wins by 0.01 again

AI trained to play video games in stepping stone to real world applications

Visitors become entrepreneurs, discover opportunities in Yunnan

Ukraine’s low-cost Shahed killers draw US and Gulf interest, but a wartime ban blocks sales

Innovation drives transformation of manufacturing industry: CPPCC member

Olympic champion Pinheiro Braathen wins World Cup giant slalom with Odermatt fifth

Trump administration and Democrats at odds over risk to US weapons stockpiles from Iran war

Lando Norris says F1 cars gone from best to 'probably the worst'

Fox ESS Achieves Record 97% Energy Storage Efficiency under HTW Rankings

Faith leaders push for access to ICE detention centers during Lent and Ramadan

China leads world in plateau medicine research-development, application: CPPCC member

Pope names veteran Vatican diplomat as ambassador to the US to manage relations with Trump

China to deepen people-centered medical reform: official

LGMG Showcases New Products and Service Initiatives at CONEXPO-CON/AGG 2026

Review: China’s space development over past five years

Long March-8A carrier rocket transferred to launch pad

China strives to build "childcare-friendly society" to address declining birth rate

Xi stresses enhancing political loyalty in military to advance defense modernization

Chinese optical clock accurate to within 1 second over 30 bln years

Max Verstappen gets X-rays on hands after crash at Australian GP qualifying

Rocket manufacturing capability should further improve to meet China's growing aerospace demands: CPPCC member

Global observers hail China's high-quality development

Chinese leaders join NPC deputies in deliberations at annual session

Chinese political advisor stresses exchanges among different civilizations in CPPCC interview

China's domestic travel hits record highs in 2025: official

GAC Chairman Highlights "Standards Going Global" to Drive High-Quality Overseas Expansion

Iran to halt strikes on neighbors unless attacked: President

Professor advocates science popularization to inspire future innovators at CPPCC session

At least 8 killed in Ukraine's Kharkiv as Russian missile hits apartment building

Iran says death toll from U.S.-Israeli strikes exceeds 1,300

China sees fruitful sci-tech innovation achievements in 2021-2025: CPPCC member

Hong Kong Police Launches Fifth Cohort of L.I.O.N. to Nurture Young Anti-Drug Leaders

NFL teams are becoming more willing to trade two first-round picks for elite defensive players

Indonesia issues RMB-denominated bonds of 9.25 billion yuan

Two Passengers Sentenced for Smuggling Duty-Not-Paid Cigarettes in Hong Kong Airport.

China's cruise giant to launch film-themed sailing season

Political advisor urges boost to China’s machine tool industry with homegrown technology

New energy boom drives up China's industrial upgrade

MIFF 2026 AWARDS HONOUR DESIGN EXCELLENCE IN THE FURNITURE INDUSTRY

AI Meets Traditional Culture: Huangshan Captures Widespread Attention at ITB Berlin

Israel launches airstrikes on Lebanon

Evacuees in Lebanon stranded as displacements soar

Global observers eye China's "two sessions", hail blueprint for high-quality development

Man Sentenced to Six Months for Illegally Importing Tobacco Products into Hong Kong.

Protests erupt in Pakistan over U.S.-Israeli attack on Iran

Thailand faces economic risks as Middle East conflict escalates

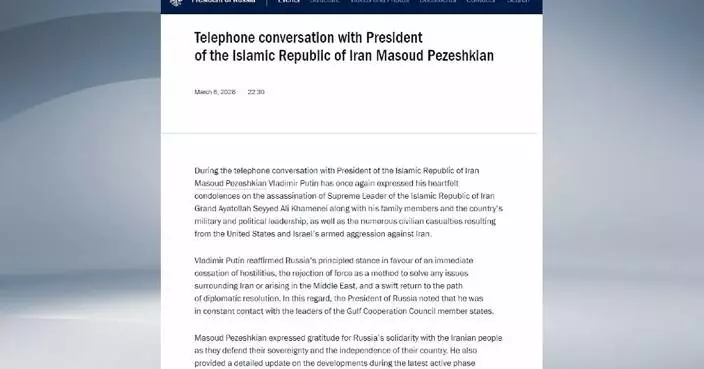

Putin urges end to Middle East hostilities in phone call with Iranian president

Health Authorities Investigate Gastroenteritis Cluster at Wong Chuk Hang Training Institute

Iranian strikes on Tel Aviv continue

Bybit Announces Departure of Co-CEO Helen Liu as She Embarks on Entrepreneurial Journey

Japanese protest against arms exports in Tokyo

US to cover Gulf maritime losses with 20 bln USD

China's foreign exchange reserves rise in February

Ahead of F1's 1st race, Red Bull welcomes 21-year-old Hadjar to the hot seat with Verstappen

Russell, Antonelli lead Mercedes in one-two qualifying positions for F1's Australian GP

Heat stop Hornets' 6-game winning streak behind 33 points from Tyler Herro

NPC deputy emphasizes long-term, systematic impact of institutional opening-up strategies

Political advisors inspired by Xi's instructions on building Healthy China

Videos show US citizen's shooting death in Texas last year by federal immigration agent