MUNICH, May 8, 2025 /PRNewswire/ -- May 7, 2025, Global photovoltaic technology innovator Polyshine Solar unveiled its new lightweight flexible photovoltaic modules and star product balcony-specific PV modules at The Smarter E Europe 2025. Its flagship new lightweight flexible module secured the TÜV NORD certification for withstanding Category 17+ hurricanes (far exceeding the traditional requirement of resisting Category 12 typhoons), attracting widespread attention from global industry players.

Three Key Highlights

Flexible Breakthrough: Polymer Materials Solve Traditional PV Limitations

Addressing the pain points of traditional glass modules – excessive weight (over 20 kg/m² including rack) and inability to adapt to low-load or curved surfaces – Polyshine Solar showcased an ultra-light flexible module weighing just 2.92 kg/m² with a bending radius of 0.5 meters. Closely aligned with the EU's REPowerEU policy, this product is poised to unlock approximately 40% of existing rooftops previously inaccessible due to load restrictions.

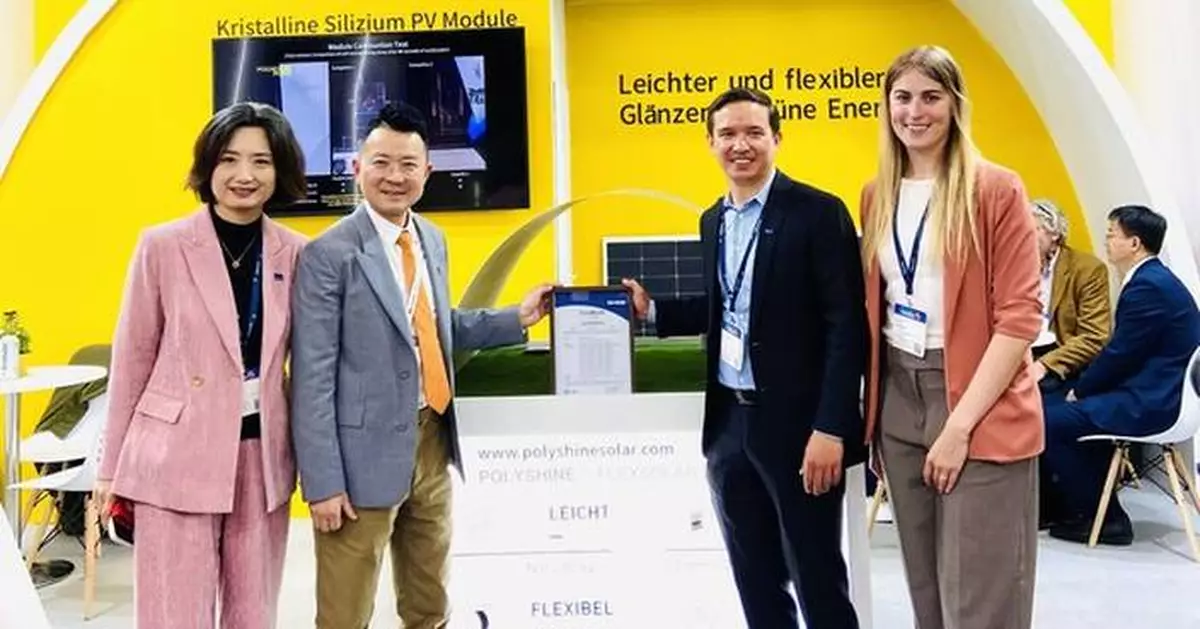

Authoritative Certification: TÜV NORD Certifies 17+ Hurricane Resistance

The international authority TÜV NORD visited Polyshine Solar booth to award the certification for Polyshine Solar's new lightweight flexible modules resisting 17+ hurricane-force winds. Based on dynamic testing at 63 m/s (17+ category) in Central South University's wind tunnel laboratory. The self-developed organic polymer material features a 300% increase in tear resistance, enabling the modules to withstand extreme wind conditions with stability.

Balcony PV: 2 minutes to install, 3 years to pay back

Designed for European residential balconies, the specialized PV module uses an innovative "zip-tie mounting system" requiring no professional tools or drilling , and one person will complete the installation within 2 minutes. Weighing just 3.3 kg and equipped , the front film achieves 91% light transmittance. Payback in as little as 3 years at €0.3/kWh (Germany residential). The 1300MPa high-modulus encapsulation technology eliminates spontaneous glass breakage (SGB) risks entirely.

Polyshine Group: 20 Years of Outdoor Application Validation Builds Quality Trust

As the technical backbone of Polyshine Solar, Polyshine Group leverages 20 years of polymer material R&D and manufacturing experience, 20 years of outdoor application data from hundreds of global projects, and 20,000 hours of accelerated aging test data to support the reliability of module encapsulation materials in outdoor environments. Through this exhibition, Polyshine Solar demonstrates that advanced material science is reshaping PV deployment boundaries – combining hurricane-level resistance with building-friendly design to accelerate global renewable energy adoption.

** The press release content is from PR Newswire. Bastille Post is not involved in its creation. **

TÜV NORD-Certified to Withstand 17+ Category Hurricanes! POLYSHINE SOLAR's Lightweight Flexible PV Modules Unveiled at THE SMARTER E EUROPE

TÜV NORD-Certified to Withstand 17+ Category Hurricanes! POLYSHINE SOLAR's Lightweight Flexible PV Modules Unveiled at THE SMARTER E EUROPE

HANOI, Vietnam, Jan. 17, 2026 /PRNewswire/ -- Viettel Group has officially broken ground on the construction of Vietnam's first semiconductor chip fabrication plant. The project is implemented by Viettel as a mission assigned by the Ministry of National Defense, in accordance with a Government Resolution.

For the first time, Vietnam is developing domestic chip fabrication capability, laying a foundation for the goal of gradually mastering core technologies and developing a domestic semiconductor ecosystem.

The plant will be built in the Hoa Lac Hi-Tech Park (Hanoi) on an area of 27 hectares, oriented to become national infrastructure serving research, design, testing, and semiconductor chip production.

Once operational, the plant will be able to serve national industries such as aerospace, telecommunications, IoT, automotive manufacturing, medical devices, and automation, among others.

A complete semiconductor chip product typically goes through six main stages: product definition, system design, detailed design, chip fabrication, packaging and testing, and integration and testing. In recent years, Vietnam has gradually participated in five of these stages; however, chip fabrication—the most complex and critical stage—has not yet been possible domestically. Building a semiconductor chip fabrication plant will help complete and close the entire semiconductor chip production process in Vietnam.

Speaking at the groundbreaking ceremony, Prime Minister of Vietnam Pham Minh Chinh emphasized: "The groundbreaking of Vietnam's first high-tech semiconductor chip fabrication plant is an event of particularly important significance. This is a step toward realizing the national semiconductor industry development strategy, creating a foundation for Vietnam to gradually participate more deeply in the global value chain, based on science, technology, and innovation."

According to the Prime Minister, the plant's presence will contribute to completing the domestic semiconductor ecosystem, enabling chip design companies, technology start-ups, and research institutions to shorten testing cycles, quickly finalize products, and bring technology into practical applications.

The plant is also expected to become a hands-on training center for the semiconductor workforce, linking training with a real production environment. Through this, Vietnam aims to train 50,000 chip design engineers under the Semiconductor Industry Human Resources Development Program through 2030, toward a scale of more than 100,000 people in Vietnam's semiconductor industry under the National Semiconductor Strategy through 2040.

For Viettel, being assigned to lead the implementation of the semiconductor chip fabrication plant continues the Group's core technology development strategy, which it has persistently pursued for many years. Viettel has proactively prepared human resources through in-depth training, international cooperation, and technology transfer, while also accumulating experience from research, design, and the application of chips in technology systems and products.

Lieutenant General Tao Duc Thang, Chairman and CEO of Viettel Group, affirmed: "Immediately after today's groundbreaking ceremony, the Group will begin implementing the project, with the set objective that by the end of 2027 we will complete the construction, receive technology transfer, and begin pilot production. The period from 2028 to 2030 will focus on finalizing and optimizing processes and improving line efficiency in accordance with industry standards, thereby serving as a basis for researching chip fabrication technology at more advanced process nodes."

The project will be implemented during 2026–2030, with a roadmap from plant construction and technology transfer to process completion and improved operational efficiency. In the long term, the Hoa Lac plant is planned to be expandable in scale, providing a foundation for Vietnam to gradually access more advanced semiconductor technologies.

The groundbreaking of the high-tech semiconductor chip fabrication plant marks an important milestone in Vietnam's journey to build technological capability, contributing to realizing the goal of "Technological self-reliance, Sustainable Future."

** The press release content is from PR Newswire. Bastille Post is not involved in its creation. **

Viettel Breaks Ground on Vietnam's First Semiconductor Chip Fabrication Plant