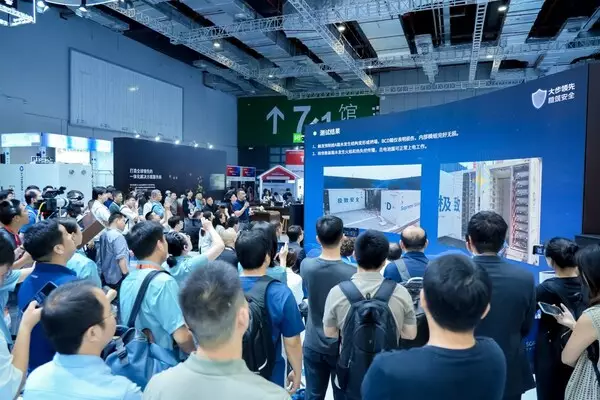

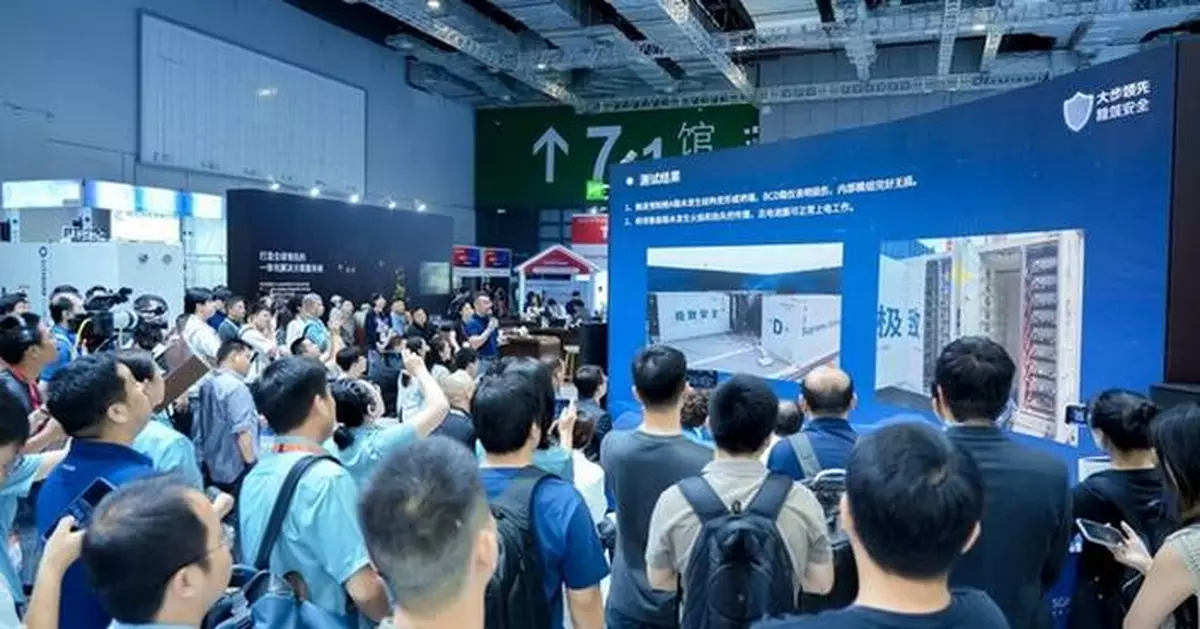

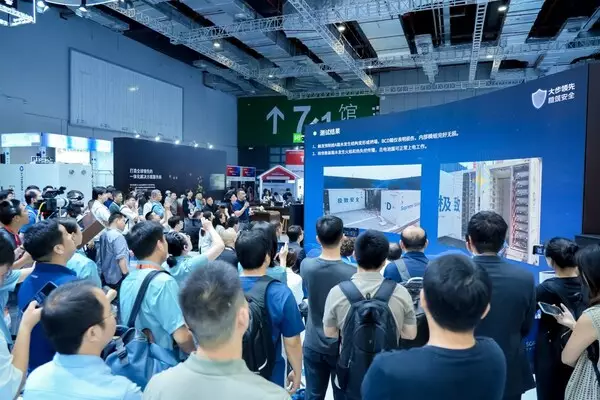

SHANGHAI, June 13, 2025 /PRNewswire/ -- On June 11, 2025, at the 18th SNEC, Hithium, a leading global energy storage technology company, held a product safety technology sharing event themed Leading the Future, Forged for Safety and unveiled the full results of the world's first all open-door large-scale fire test of its ∞Block 5MWh energy storage system, and was also awarded the large-scale fire test certification by international testing authority UL Solutions.

Hualei Wang, project manager for the fire test, shared an overview of the test background and key details. A video of the open-door fire test was also shown on-site, offering a comprehensive view of the test procedure, technical highlights, and results.

The open-door fire test was initiated by intentionally heating eight battery cells inside container A to trigger thermal runaway, causing propagation between cells. As the battery's pressure relief vents opened, an ignition system ignited the released gases, initiating full combustion with the container doors kept wide open to allow continuous oxygen flow. This setup maximized heat exposure to adjacent containers B, C, and D. The test was conducted under four extreme conditions: all open-door combustion, dual 15 cm extreme spacing, fire suppression system deactivated, and 100% State of Charge (SOC).

- Peak Fire Phase: At the fourth hour of testing, the fire reached its peak temperature of 1,372°C. Temperature monitoring confirmed that cell temperatures in all adjacent containers remained well below the cell thermal runaway initiation threshold defined by the UL9540A cell-level test (≤42°C in Container B, ≤80°C in Container C, and ≤70°C in Container D).

- Sustained Combustion Phase: After 15 hours of combustion, the open flame was extinguished. The initiating container remained structurally intact without deformation or collapse. No combustion or thermal runaway propagation occurred in the three adjacent containers. Containers B, C, and D only experienced minor surface damage, while internal battery modules remained completely unaffected.

The completion of the test was made possible by Hithium's multi-layered safety architecture, spanning the cell, module, and system levels. At the cell level, heat-resistant anode/cathode materials, functional electrolyte additives, and high-temperature separators raised thermal thresholds. At the module level, low-conductivity insulation and flame-retardant top covers minimized propagation risk. At the system level, a high-strength container frame and heat-resistant enclosure materials maintained structural stability under extreme heat.

At the event, UL Solutions awarded Hithium a certification for the large-scale fire test, recognizing its compliance with UL 9540A and NFPA 855 standards. Qifeng Xiao, General Manager of the Energy and Automation Division, Asia Pacific at UL Solutions, stated at the certification ceremony, "Hithium's pioneering open-door extreme fire test was the first to be conducted under full oxygen exposure—far beyond the industry standard closed-door with explosion vent fire test model. The positive outcome not only validated the system's self-contained fire protection, but also established a valuable reference for the development of global energy storage safety standards through the world's first open-door fire test."

This pioneering fire test not only demonstrated Hithium's strong technical capabilities but also reflected its full confidence in the safety performance of its energy storage systems through a fully transparent testing process, contributing important data and practices to the industry. Hithium will continue to invest in safety innovation—tightening the "seatbelt" for the global transition to green energy.

** The press release content is from PR Newswire. Bastille Post is not involved in its creation. **

SNEC 2025|Hithium Defines a New Benchmark for Energy Storage Safety with the World's First All Open-Door Large-Scale Fire Test

|

Landmark Project Across Four Governorates to Boost Power Plant Output by 50%, Easing Chronic Electricity Shortages

SHANGHAI, Dec. 20, 2025 /PRNewswire/ -- Shanghai Electric has broken ground on the Euphrates Combined Cycle Expansion Project in Iraq. As the project's contractor, Shanghai Electric is upgrading power plants across four Iraqi governorates by transforming simple-cycle units into combined-cycle systems. The expansion will add a total capacity of 625 megawatts (MW) and is designed to boost overall plant efficiency by approximately 50%, generating an additional 5 billion kilowatt-hprojours (kWh) of electricity annually without increasing fuel consumption. This initiative is poised to significantly alleviate the country's persistent electricity shortages.

"The pressing need for energy security and development in Iraq is clear. We are honored that our efficient combined-cycle technology is recognized as instrumental in modernizing this critical infrastructure," said a spokesperson for Shanghai Electric. "This project exemplifies our commitment to supporting the energy security and green development of Belt and Road countries through technological innovation."

Iraq, a major Middle Eastern oil producer, has faced severe power shortages for over three decades. Most of its power plants rely on natural gas, yet domestic gas development lags, creating a heavy dependence on imports. This power deficit has become a persistent challenge to people's livelihoods and a bottleneck for national reconstruction and economic growth.

The Shanghai Electric-contracted expansion project along the Euphrates River broke ground early this year and covers the Iraqi governorates of Najaf, Karbala, Babylon, and Al-Qadisiyyah, with all upgrades centered on advanced combined-cycle technology. Core equipment has now arrived on site, and construction is advancing through the collaboration of Chinese and Iraqi teams. Since its commencement, the project has drawn considerable attention from the Iraqi government and public.

Iraqi Minister of Electricity Ziad Ali Fadel has praised the project's strategic importance, stating, "This initiative is highly significant for improving Iraq's power supply and optimizing its electricity infrastructure. Once operational, it will effectively reduce Iraq's reliance on imported natural gas and lower its fuel costs for power generation."

At the power plant in Najaf, the upgrade utilizes high-temperature exhaust from existing gas turbines as a heat source. The exhaust is directed through heat recovery steam generators to produce high-pressure steam, which then drives a new steam turbine to create additional electricity. This combined-cycle process increases output and efficiency without extra fuel and reduces the thermal pollution from the original units.

Naseem Ayad, the Iraqi project manager at the Najaf site, said, "Chinese equipment and power technology help us reuse high-temperature exhaust, boosting generation capacity while reducing thermal pollution. This project sets a benchmark for power plant upgrades in Iraq and reflects local hopes for more reliable electricity and better living conditions."

At the Karbala site, core equipment such as heat recovery steam generators and direct air-cooled condensers have been delivered. This project phase marks one of Iraq's first combined-cycle expansions to fully utilize Chinese equipment and standards, with core systems designed and manufactured in China. This will effectively drive the overseas deployment of Chinese equipment and enhance the recognition of Chinese standards in Iraq.

Upon completion, the project is expected to improve local livelihoods, support post-war reconstruction, and lay a robust energy foundation for Iraq's industrial recovery and economic growth.

Shanghai Electric remains dedicated to supporting sustainable development in Belt and Road regions and worldwide through advanced, efficient, and eco-friendly energy technologies.

For more information, please visit https://www.shanghai-electric.com/group_en/.

Landmark Project Across Four Governorates to Boost Power Plant Output by 50%, Easing Chronic Electricity Shortages

SHANGHAI, Dec. 20, 2025 /PRNewswire/ -- Shanghai Electric has broken ground on the Euphrates Combined Cycle Expansion Project in Iraq. As the project's contractor, Shanghai Electric is upgrading power plants across four Iraqi governorates by transforming simple-cycle units into combined-cycle systems. The expansion will add a total capacity of 625 megawatts (MW) and is designed to boost overall plant efficiency by approximately 50%, generating an additional 5 billion kilowatt-hprojours (kWh) of electricity annually without increasing fuel consumption. This initiative is poised to significantly alleviate the country's persistent electricity shortages.

"The pressing need for energy security and development in Iraq is clear. We are honored that our efficient combined-cycle technology is recognized as instrumental in modernizing this critical infrastructure," said a spokesperson for Shanghai Electric. "This project exemplifies our commitment to supporting the energy security and green development of Belt and Road countries through technological innovation."

Iraq, a major Middle Eastern oil producer, has faced severe power shortages for over three decades. Most of its power plants rely on natural gas, yet domestic gas development lags, creating a heavy dependence on imports. This power deficit has become a persistent challenge to people's livelihoods and a bottleneck for national reconstruction and economic growth.

The Shanghai Electric-contracted expansion project along the Euphrates River broke ground early this year and covers the Iraqi governorates of Najaf, Karbala, Babylon, and Al-Qadisiyyah, with all upgrades centered on advanced combined-cycle technology. Core equipment has now arrived on site, and construction is advancing through the collaboration of Chinese and Iraqi teams. Since its commencement, the project has drawn considerable attention from the Iraqi government and public.

Iraqi Minister of Electricity Ziad Ali Fadel has praised the project's strategic importance, stating, "This initiative is highly significant for improving Iraq's power supply and optimizing its electricity infrastructure. Once operational, it will effectively reduce Iraq's reliance on imported natural gas and lower its fuel costs for power generation."

At the power plant in Najaf, the upgrade utilizes high-temperature exhaust from existing gas turbines as a heat source. The exhaust is directed through heat recovery steam generators to produce high-pressure steam, which then drives a new steam turbine to create additional electricity. This combined-cycle process increases output and efficiency without extra fuel and reduces the thermal pollution from the original units.

Naseem Ayad, the Iraqi project manager at the Najaf site, said, "Chinese equipment and power technology help us reuse high-temperature exhaust, boosting generation capacity while reducing thermal pollution. This project sets a benchmark for power plant upgrades in Iraq and reflects local hopes for more reliable electricity and better living conditions."

At the Karbala site, core equipment such as heat recovery steam generators and direct air-cooled condensers have been delivered. This project phase marks one of Iraq's first combined-cycle expansions to fully utilize Chinese equipment and standards, with core systems designed and manufactured in China. This will effectively drive the overseas deployment of Chinese equipment and enhance the recognition of Chinese standards in Iraq.

Upon completion, the project is expected to improve local livelihoods, support post-war reconstruction, and lay a robust energy foundation for Iraq's industrial recovery and economic growth.

Shanghai Electric remains dedicated to supporting sustainable development in Belt and Road regions and worldwide through advanced, efficient, and eco-friendly energy technologies.

For more information, please visit https://www.shanghai-electric.com/group_en/.

** The press release content is from PR Newswire. Bastille Post is not involved in its creation. **

Shanghai Electric Powers Up Iraq's Energy Future with Major 625MW Efficiency Upgrade