|

DSC Creates a Greener, Smarter Approach to Manufacturing without Sacrificing Performance

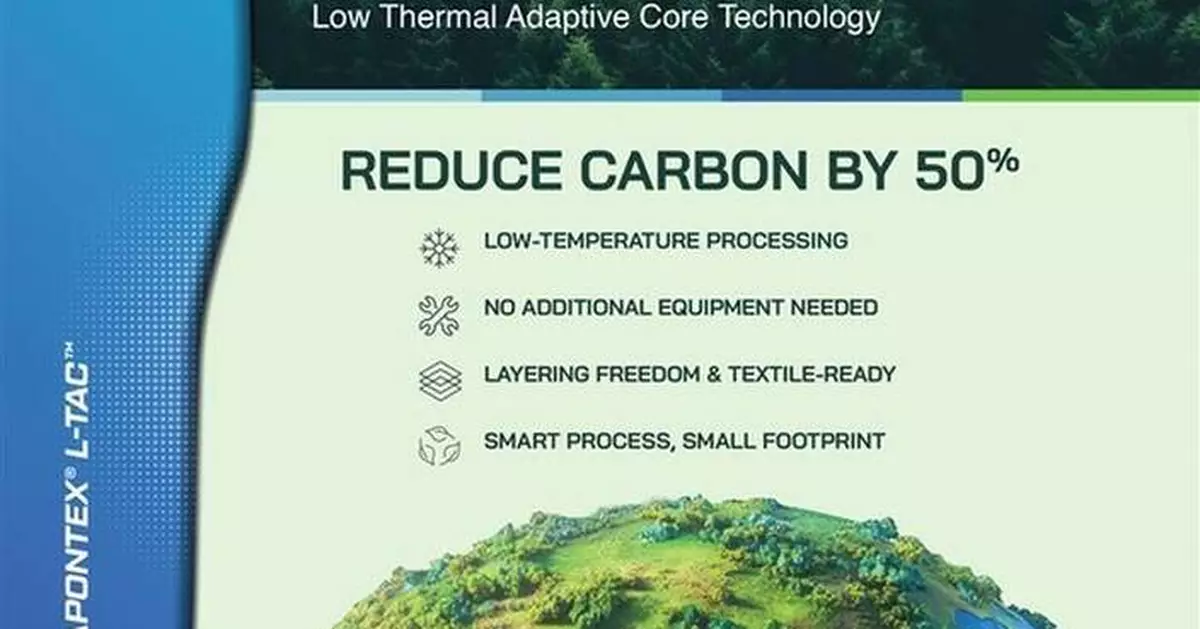

PORTLAND, Ore., Sept. 24, 2025 /PRNewswire/ -- DSC®, a global leader in high performance foam innovation, today announced the launch of DURAPONTEX® L-TAC, a next-generation foam technology that redefines sustainable footwear manufacturing. Engineered to mold at significantly lower temperatures, L-TAC not only reduces energy usage and carbon emissions per pair, but also expands design freedom for brands by enabling compatibility with a broader range of textiles.

Traditional closed- or open-cell foams require high processing temperatures which can limit the use of delicate fabrics such as leathers or specialty synthetics. DURAPONTEX® L-TAC molds at just 120°C, protecting sensitive materials from heat distortion, opening up new creative possibilities for designers. Importantly, the technology integrates seamlessly into existing production lines, requiring no new machinery.

"With DURAPONTEX® L-TAC, we're proving that sustainability and design innovation can go hand in hand," said Mei-Fen Wei, Chief Operating Officer of DSC®. "By reducing energy by up to 50% and giving designers the freedom to work with materials that were previously off-limits, L-TAC represents a real step forward for the footwear industry with a smarter, greener approach to manufacturing. Every pair truly counts."

Key Benefits of DURAPONTEX® L-TAC:

- Low-Temperature Thermoforming – Molds at 120°C (compared to traditional foams at 160–190°C), and protects delicate fabrics and materials.

- Energy Efficient & Sustainable – DSC's internal testing lab shows up to a 50% reduction in energy usage and carbon emissions per pair without sacrificing performance, compared to traditional closed cell foam. 11,000 kilowatt-hour (kWh) saved* in the production process is equivalent to enough energy to power 300 households for a month. *Per million insoles.

- Durable & Reliable – Engineered for shape retention and structural integrity under high performance demands.

- Seamless Integration – Requires no machinery or retooling; ready to deploy in high-volume production.

DURAPONTEX® L-TAC is available in multiple hardness levels (23 +/- 3 AskerC, 28 +/- 3 AskerC and 33 +/- 3 AskerC) in molded or die-cut insole formats. A softer variant is also available for upper applications with a great hand feel. With DURAPONTEX® L-TAC, DSC® continues its commitment to delivering innovations that empower performance brands to meet both creative and sustainability goals without compromise.

For 80 years since its founding in 1945, Dahsheng Company (DSC®) has been a leader in foam innovation for the sports industries. Known for its premium comfort and performance foam DREAMCELL® and DURAPONTEX®, DSC® partners with top brands and footwear manufacturers worldwide. By advancing innovation and pushing the limits of foam manufacturing, DSC® is dedicated to creating eco-friendly and advanced foam solutions that set new standards in the industry.

Visit www.dahsheng.com to learn more about DSC® and its commitment to sustainability and eco-innovation.

Media Contact:

Erin Patterson

t: +1-323-422-0274

e: erin.patterson@writetheskycomms.com

DSC Creates a Greener, Smarter Approach to Manufacturing without Sacrificing Performance

PORTLAND, Ore., Sept. 24, 2025 /PRNewswire/ -- DSC®, a global leader in high performance foam innovation, today announced the launch of DURAPONTEX® L-TAC, a next-generation foam technology that redefines sustainable footwear manufacturing. Engineered to mold at significantly lower temperatures, L-TAC not only reduces energy usage and carbon emissions per pair, but also expands design freedom for brands by enabling compatibility with a broader range of textiles.

Traditional closed- or open-cell foams require high processing temperatures which can limit the use of delicate fabrics such as leathers or specialty synthetics. DURAPONTEX® L-TAC molds at just 120°C, protecting sensitive materials from heat distortion, opening up new creative possibilities for designers. Importantly, the technology integrates seamlessly into existing production lines, requiring no new machinery.

"With DURAPONTEX® L-TAC, we're proving that sustainability and design innovation can go hand in hand," said Mei-Fen Wei, Chief Operating Officer of DSC®. "By reducing energy by up to 50% and giving designers the freedom to work with materials that were previously off-limits, L-TAC represents a real step forward for the footwear industry with a smarter, greener approach to manufacturing. Every pair truly counts."

Key Benefits of DURAPONTEX® L-TAC:

- Low-Temperature Thermoforming – Molds at 120°C (compared to traditional foams at 160–190°C), and protects delicate fabrics and materials.

- Energy Efficient & Sustainable – DSC's internal testing lab shows up to a 50% reduction in energy usage and carbon emissions per pair without sacrificing performance, compared to traditional closed cell foam. 11,000 kilowatt-hour (kWh) saved* in the production process is equivalent to enough energy to power 300 households for a month. *Per million insoles.

- Durable & Reliable – Engineered for shape retention and structural integrity under high performance demands.

- Seamless Integration – Requires no machinery or retooling; ready to deploy in high-volume production.

DURAPONTEX® L-TAC is available in multiple hardness levels (23 +/- 3 AskerC, 28 +/- 3 AskerC and 33 +/- 3 AskerC) in molded or die-cut insole formats. A softer variant is also available for upper applications with a great hand feel. With DURAPONTEX® L-TAC, DSC® continues its commitment to delivering innovations that empower performance brands to meet both creative and sustainability goals without compromise.

For 80 years since its founding in 1945, Dahsheng Company (DSC®) has been a leader in foam innovation for the sports industries. Known for its premium comfort and performance foam DREAMCELL® and DURAPONTEX®, DSC® partners with top brands and footwear manufacturers worldwide. By advancing innovation and pushing the limits of foam manufacturing, DSC® is dedicated to creating eco-friendly and advanced foam solutions that set new standards in the industry.

Visit www.dahsheng.com to learn more about DSC® and its commitment to sustainability and eco-innovation.

Media Contact:

Erin Patterson

t: +1-323-422-0274

e: erin.patterson@writetheskycomms.com

** The press release content is from PR Newswire. Bastille Post is not involved in its creation. **

DSC® Launches DURAPONTEX® L-TAC: A Breakthrough Low-Temp Foam Technology Reducing Energy Usage

SHANGHAI, Jan. 15, 2026 /PRNewswire/ -- HOTELEX Shanghai 2026 will take place from 30th March to 2nd April 2026, offering global hospitality and foodservice suppliers a direct gateway to China and the wider Asian market. Building on the record-breaking success of the 2025 edition, the exhibition will return with expanded scale, stronger international buyer engagement, and enhanced commercial value. With over 3,500 exhibitors, 12,000 overseas buyers, and a fully integrated industry ecosystem, HOTELEX Shanghai 2026 provides a high-impact platform for sourcing, partnerships, and long-term market expansion.

HOTELEX Shanghai 2025 welcomed a record 284,581 professional visitors, including a 34.2% increase in international buyers. Exhibitors reported a 37% rise in qualified leads and a 23% increase in on-site transactions, demonstrating the exhibition's effectiveness as a high-performance sourcing and business platform. Building on this success, the 34ᵗʰ edition in 2026 will offer expanded exhibition space, deeper international participation, and increased opportunities for global decision-makers, distributors, and strategic partners.

Covering 400,000 square meters, the exhibition will host more than 3,500 leading domestic and international suppliers across key sectors including Kitchen Equipment, Coffee & Tea, Catering Ingredients, Beverages, and Baking Supplies. This fully integrated ecosystem supports end-to-end sourcing, innovation, and cross-border collaboration.

HOTELEX's competitive advantage lies in its comprehensive industry coverage. By integrating resources across hospitality, catering, cultural tourism, retail, logistics, and health sectors, the exhibition drives value-chain synergies and reflects the evolving structure of the modern hospitality economy. Its distinctive "tourism–catering–hotel joint exhibition" model offers a holistic showcase spanning food, accommodation, travel, shopping, and leisure.

Leveraging a shared pool of over 100,000 professional buyers from HOTELEX and FHC, exhibitors gain extended brand exposure through official digital platforms and global social media channels including LinkedIn, YouTube, Facebook, and TikTok, as well as partnerships with authoritative industry media. Booths are limited – reserve yours early to secure prime exhibition space and maximize business opportunities. Positioned as a strategic gateway, HOTELEX Shanghai 2026 empowers global companies to grow their presence in China and accelerate expansion across Asia's hospitality and foodservice markets.

Pre-registration: https://www.hotelex.cn/en/shanghai

Contact Us:

Booth Inquiry:

Jason Jin

Tel: +86 21 3339 2197

Junyan.Jin@imsinoexpo.com

Media & Visitor Consulting:

Lizzy Chen

Tel: +86 21 3339 2566

Lizzy.chen@imsinoexpo.com

** The press release content is from PR Newswire. Bastille Post is not involved in its creation. **

Maximize Your Business Growth in Asia's Hospitality & Foodservice Market at HOTELEX 2026