|

- The new game-changer Pocan® PBT exhibits high elongation at break, good tracking resistance combined with hydrolysis resistance while also being flame-retardant, dimensionally stable, and electrically insulating even at elevated temperatures.

- Ideal for use in connectors for ultrafast high-voltage charging, secondary 48-volt board supply, and AI data center applications.

- This material innovation expands Envalior's portfolio of highly tracking-resistant materials for connectors and other components.

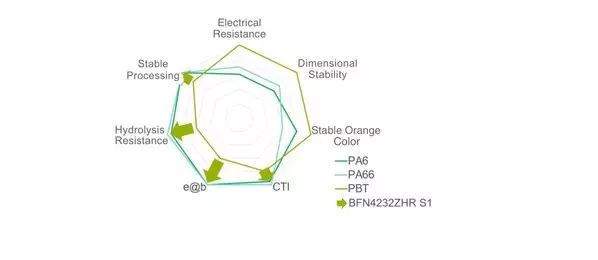

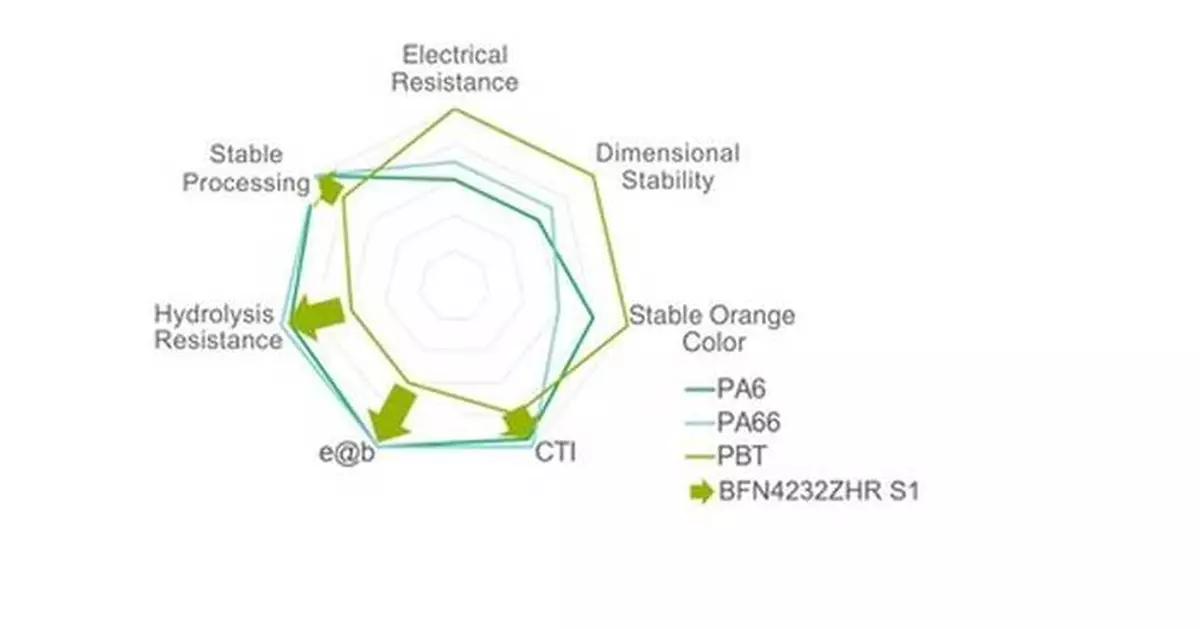

DÜSSELDORF, Germany, Oct. 8, 2025 /PRNewswire/ -- Envalior has achieved a breakthrough in materials for high-voltage plastic components. With Pocan® BFN4232ZHR S1, the manufacturer of sustainable and high-performance engineering materials is launching a new, halogen-free flame-retardant polybutylene terephthalate (PBT) that combines the advantages of PBT and polyamide 6 and 66. It exhibits typical PBT strengths, such as high dimensional stability, low propensity for electro corrosion, and excellent electrical insulation behavior at higher temperatures while also offering the high hydrolysis resistance, creep resistance, and elongation at break comparable to polyamide 6 and 66. With this property profile, it is now being considered for applications that have traditionally been dominated by polyamide.

"We see great application potential above all in connectors used in ultrafast-charging stations for electric cars with charging voltages of 800 volts and above, in 800-volt power supply systems for AI data centers, and also in secondary 48-volt board supply, for example for hybrid vehicles. Other potential applications include housings and electrical components in the rapidly growing market for smart grid devices," explains Dr. Jochen Endtner, Head of Product Development for Pocan® at Envalior.

Envalior plans to add further material variants with different glass fiber contents to the new PBT, which are optimized in terms of specific properties. Material grades are now available that can be precisely marked in all colors using laser marking, for example with data matrix codes. Envalior also offers the new material based on renewable raw materials (bio-based butanediol).

High elongation at break provides greater design freedom and broader application use

One highlight of the new Pocan® PBT is its high elongation at break of over 2.5 percent (ISO 527-1,-2), which is comparable to that of polyamide compounds with flame retardant additive packages. Components made from this material absorb more energy under load, which means they do not break as easily and are less prone to stress cracks. This enables greater design freedom and expands the range of possible applications for the compound. The excellent elongation at break is retained even after numerous extreme temperature changes because the material is highly resistant to hydrolysis and heat aging.

Excellent test results in hydrolysis, flame retardancy, and tracking resistance

The new compound demonstrates excellent hydrolysis resistance in specimen tests. Important mechanical properties, such as elongation at break remain well above 70% after 1,000 hours of storage at 85°C and 85% relative humidity. In long-term tests based on the strict SAE/USCAR 2 Rev.7 standards of the US Society of Automotive Engineers (SAE), USCAR Class 3 is achieved. It is precisely this high hydrolysis resistance that opens up applications for the thermoplastic that were previously reserved for polyamide.

With its tracking resistance, the compound achieves the best possible rating of 600 in the CTI A test (Comparative Tracking Index, IEC 60112). It therefore meets the requirements of the highest insulation class according to IEC 60664-1. This rating also applies to orange and black coloring, which is unique for a PBT compound reinforced with 25 percent glass fibers.

The UL 94 fire test of the US Underwriters Laboratories Inc. is passed with the classification V-0 at a test specimen thickness of 0.75 millimeters in all colors. This is important, for example, for the color coding of connectors in cable harnesses.

"The compound's high flame resistance and tracking resistance make it easier for designers to create very thin-walled and compact components without compromising electrical safety. This results in low material consumption and ideal use of the installation space," says Endtner.

The long-term stability of the thermoplastic in hot air was also tested. For example, its tensile strength remains at a high level after 3,000 hours of hot air storage at 150°C.

Designed for safe processing and free from substances of concern

Pocan® BFN4232ZHR S1 is free from halogenated ingredients and also contains no polyfluorinated alkyl substances (PFAS), which are the subject of debate as forever chemicals. Furthermore, its additives do not release any decomposition products known to be harmful to occupational health, such as isocyanates or phosphine, during injection molding.

"We are thus offering a design material that does not require a high level of occupational safety measures and meets all current and expected regulatory requirements in the near future. Our customers can therefore rely on being able to use the compound safely and long-term," explains Endtner.

Numerous material solutions with high CTI values for connectors

Envalior offers a broad range of halogen-free flame-retardant compounds from different material classes, which are ideal for high-voltage connectors thanks to their high CTI value of 600, UL 94 V-0 classification, and high-quality mechanical properties. These include, for example, the dimensionally stable, mechanically and thermally highly resilient polyphthalamide compounds ForTii® or various polyamide 66 products Akulon®. The latter include grades that minimize the corrosion of silicone seals in connectors, contributing to a permanently high sealing performance.

Visit Envalior for more information at K 2025 (Hall 6, Stand B11, Oct. 8-15, 2025, Messe Düsseldorf, Germany) and The Battery Show North America 2025 (Booth #408, Oct. 6-9, 2025, Detroit, MI, U.S.), or at https://www.envalior.com/en-us/products.html.

Detailed information on Envalior's materials can be found in Envalior's MaterialAdvisor, which provides digital tools and services that customers can use to find, select and evaluate materials.

About Envalior

Envalior is a global leader in Engineering Materials with over 4,000 employees worldwide. It was established in 2023 through the merger of Lanxess Performance Materials and DSM Engineering Materials. With a long track record of customer-driven innovation, Envalior specializes in developing Sustainable and High-Performance Engineering Materials, including PA6, PA66, PBT, PA46, PPS, TPC, PET, PA4T, PA410, and Thermoplastic Composites. Focus markets include Mobility, Electronics & Electrical, and Consumer Goods. For more information, visit www.envalior.com.

- The new game-changer Pocan® PBT exhibits high elongation at break, good tracking resistance combined with hydrolysis resistance while also being flame-retardant, dimensionally stable, and electrically insulating even at elevated temperatures.

- Ideal for use in connectors for ultrafast high-voltage charging, secondary 48-volt board supply, and AI data center applications.

- This material innovation expands Envalior's portfolio of highly tracking-resistant materials for connectors and other components.

DÜSSELDORF, Germany, Oct. 8, 2025 /PRNewswire/ -- Envalior has achieved a breakthrough in materials for high-voltage plastic components. With Pocan® BFN4232ZHR S1, the manufacturer of sustainable and high-performance engineering materials is launching a new, halogen-free flame-retardant polybutylene terephthalate (PBT) that combines the advantages of PBT and polyamide 6 and 66. It exhibits typical PBT strengths, such as high dimensional stability, low propensity for electro corrosion, and excellent electrical insulation behavior at higher temperatures while also offering the high hydrolysis resistance, creep resistance, and elongation at break comparable to polyamide 6 and 66. With this property profile, it is now being considered for applications that have traditionally been dominated by polyamide.

"We see great application potential above all in connectors used in ultrafast-charging stations for electric cars with charging voltages of 800 volts and above, in 800-volt power supply systems for AI data centers, and also in secondary 48-volt board supply, for example for hybrid vehicles. Other potential applications include housings and electrical components in the rapidly growing market for smart grid devices," explains Dr. Jochen Endtner, Head of Product Development for Pocan® at Envalior.

Envalior plans to add further material variants with different glass fiber contents to the new PBT, which are optimized in terms of specific properties. Material grades are now available that can be precisely marked in all colors using laser marking, for example with data matrix codes. Envalior also offers the new material based on renewable raw materials (bio-based butanediol).

High elongation at break provides greater design freedom and broader application use

One highlight of the new Pocan® PBT is its high elongation at break of over 2.5 percent (ISO 527-1,-2), which is comparable to that of polyamide compounds with flame retardant additive packages. Components made from this material absorb more energy under load, which means they do not break as easily and are less prone to stress cracks. This enables greater design freedom and expands the range of possible applications for the compound. The excellent elongation at break is retained even after numerous extreme temperature changes because the material is highly resistant to hydrolysis and heat aging.

Excellent test results in hydrolysis, flame retardancy, and tracking resistance

The new compound demonstrates excellent hydrolysis resistance in specimen tests. Important mechanical properties, such as elongation at break remain well above 70% after 1,000 hours of storage at 85°C and 85% relative humidity. In long-term tests based on the strict SAE/USCAR 2 Rev.7 standards of the US Society of Automotive Engineers (SAE), USCAR Class 3 is achieved. It is precisely this high hydrolysis resistance that opens up applications for the thermoplastic that were previously reserved for polyamide.

With its tracking resistance, the compound achieves the best possible rating of 600 in the CTI A test (Comparative Tracking Index, IEC 60112). It therefore meets the requirements of the highest insulation class according to IEC 60664-1. This rating also applies to orange and black coloring, which is unique for a PBT compound reinforced with 25 percent glass fibers.

The UL 94 fire test of the US Underwriters Laboratories Inc. is passed with the classification V-0 at a test specimen thickness of 0.75 millimeters in all colors. This is important, for example, for the color coding of connectors in cable harnesses.

"The compound's high flame resistance and tracking resistance make it easier for designers to create very thin-walled and compact components without compromising electrical safety. This results in low material consumption and ideal use of the installation space," says Endtner.

The long-term stability of the thermoplastic in hot air was also tested. For example, its tensile strength remains at a high level after 3,000 hours of hot air storage at 150°C.

Designed for safe processing and free from substances of concern

Pocan® BFN4232ZHR S1 is free from halogenated ingredients and also contains no polyfluorinated alkyl substances (PFAS), which are the subject of debate as forever chemicals. Furthermore, its additives do not release any decomposition products known to be harmful to occupational health, such as isocyanates or phosphine, during injection molding.

"We are thus offering a design material that does not require a high level of occupational safety measures and meets all current and expected regulatory requirements in the near future. Our customers can therefore rely on being able to use the compound safely and long-term," explains Endtner.

Numerous material solutions with high CTI values for connectors

Envalior offers a broad range of halogen-free flame-retardant compounds from different material classes, which are ideal for high-voltage connectors thanks to their high CTI value of 600, UL 94 V-0 classification, and high-quality mechanical properties. These include, for example, the dimensionally stable, mechanically and thermally highly resilient polyphthalamide compounds ForTii® or various polyamide 66 products Akulon®. The latter include grades that minimize the corrosion of silicone seals in connectors, contributing to a permanently high sealing performance.

Visit Envalior for more information at K 2025 (Hall 6, Stand B11, Oct. 8-15, 2025, Messe Düsseldorf, Germany) and The Battery Show North America 2025 (Booth #408, Oct. 6-9, 2025, Detroit, MI, U.S.), or at https://www.envalior.com/en-us/products.html.

Detailed information on Envalior's materials can be found in Envalior's MaterialAdvisor, which provides digital tools and services that customers can use to find, select and evaluate materials.

About Envalior

Envalior is a global leader in Engineering Materials with over 4,000 employees worldwide. It was established in 2023 through the merger of Lanxess Performance Materials and DSM Engineering Materials. With a long track record of customer-driven innovation, Envalior specializes in developing Sustainable and High-Performance Engineering Materials, including PA6, PA66, PBT, PA46, PPS, TPC, PET, PA4T, PA410, and Thermoplastic Composites. Focus markets include Mobility, Electronics & Electrical, and Consumer Goods. For more information, visit www.envalior.com.

** The press release content is from PR Newswire. Bastille Post is not involved in its creation. **

NEW PBT FROM ENVALIOR, DEBUTING AT K 2025 & THE BATTERY SHOW NORTH AMERICA, SETS STANDARD FOR HIGH-VOLTAGE APPLICATIONS

NEW PBT FROM ENVALIOR, DEBUTING AT K 2025 & THE BATTERY SHOW NORTH AMERICA, SETS STANDARD FOR HIGH-VOLTAGE APPLICATIONS

JINGMEN, China, Jan. 18, 2026 /PRNewswire/ -- A flagship facility of EVE Energy (300014.SZ) has been inducted into the Global Lighthouse Network by the World Economic Forum and McKinsey & Company, making it as the world's first lighthouse factory in the cylindrical battery sector. This distinguished recognition, symbolizing the pinnacle of global smart and digital manufacturing, underscores EVE Energy's pioneering role in end-to-end smart transformation, powered by the deployment of 40+ digital solutions.

Smart Manufacturing Drives High Production Efficiency

EVE has built a complete digital system across R&D, production, and sales, launching China's first 300ppm high-speed cylindrical batteries production line, capable of producing 300 batteries per minute per line.

- Physical simulation and AI integration enable intelligent outcome prediction and process-parameter optimization in seconds, reducing 75% of R&D experiments.

- Key production processes achieve 100% automation, and an AIoT-driven predictive equipment health system ensures 24/7 operation, boosting the maximum overall equipment efficiency (OEE) to 95%.

- For sales, the APS intelligent scheduling system analyzes global orders in seconds, reducing lead-time response by 50%.

Full-Process AI Quality Control System Ensures Consistent Quality

A full-process intelligent quality control system ensures 97%+ first-pass yield and 70% improvement in cell voltage consistency via real-time data monitoring and cross-process AI optimization during production. AI vision inspection achieves 100% inspection with zero missed judgments in 0.3 seconds per cell. Supported by a full-lifecycle battery data space, quality issues can be traced and improved within seconds.

Green Initiatives Drive Eco-Social Sustainability

From 2022 to 2025, EVE Energy achieved 60%+ and 55%+ reductions in per-unit carbon emissions and product energy consumption. Real-time optimization via an AI-driven energy management model targets high-consuming systems, while the innovative "Battery Passport" system provides each battery with a unique digital identifier, encompassing 200,000+ supply chain nodes to enable precise recycling. Through renewable energy, recycled materials, and energy-saving upgrades, EVE has cut the product's full-lifecycle carbon footprint by 15%.

EVE advances human-machine synergy: AR training and remote expert guidance accelerate skill development for key roles from months to days, empowering operators to oversee advanced algorithms. A 360° air-ground security platform integrates over 1,000 intelligent sensors and UAV inspections, achieving zero production accidents with AI real-time risk warnings.

EVE Energy demonstrates how digital technologies can drive simultaneous advancements in both manufacturing efficiency and green performance. This is poised to inspire industry peers to pursue high-quality and low-carbon pathways, advancing global sustainability efforts.

** The press release content is from PR Newswire. Bastille Post is not involved in its creation. **

World's First Cylindrical Battery Lighthouse Factory: EVE Energy Sets a New Benchmark in Smart Manufacturing