|

SHENZHEN, China, Dec. 19, 2025 /PRNewswire/ -- Following the release of its annual ESG report in June 2025, TCL Technology is proud to highlight its progress on water resource protection and green technology innovation, which are key pillars in addressing environmental challenges and building a low-carbon future. TCL Technology prioritizes water resource management and the development of clean technologies as critical components of its strategy to foster green transformation and advance sustainability on a global scale.

Comprehensive Water Resource Management: From Risk Control to Circular Economy

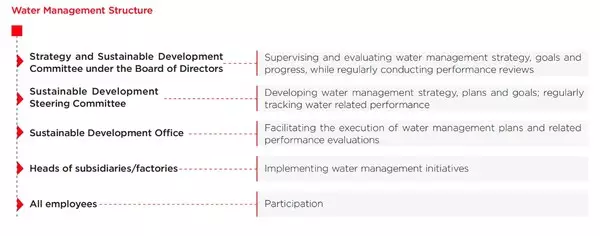

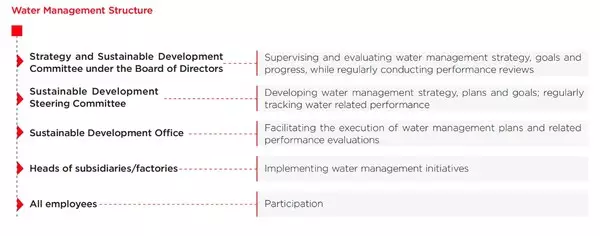

TCL Technology demonstrates its leadership in water resource management through a robust governance framework. The Strategy and Sustainability Committee under the Group's Board of Directors oversees water management strategies and performance, ensuring continuous improvement and adherence to conservation principles across all subsidiaries. By combining sound policies, technological innovation, and comprehensive process control, the Company has built a robust and efficient water resource management system.

TCL Technology embeds water resource management into its corporate governance framework, using policies to guide implementation. For example, TCL CSOT has introduced a Water Resource Management Policy, comprising six sub-policies that outline responsibilities for conservation, resource planning, and inspections. This creates a closed-loop control process from target-setting to implementation and oversight. Similarly, TCL Zhonghuan incorporates water resource management indicators into its ESG performance evaluation framework as part of its Environmental Management Policy, linking plant manager performance to executive remuneration to ensure operational accountability.

Technological innovation and process optimization drive TCL Technology's efforts to use water resources efficiently:

- Guangzhou TCL CSOT: Optimized brine reuse and rainwater collection systems, forming a closed-loop framework covering production, recycling, and reuse.

- Wuhan TCL CSOT: Adopted membrane separation to treat fluoride-bearing wastewater, enabling the reuse of 780,000 cubic meters of water annually. Additional measures, such as chemical precipitation to reduce heavy metals in silver-bearing wastewater and a wetland-based rainwater reuse system, integrate gray infrastructure with ecological solutions.

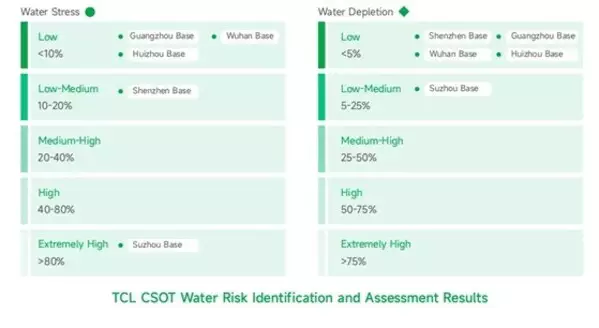

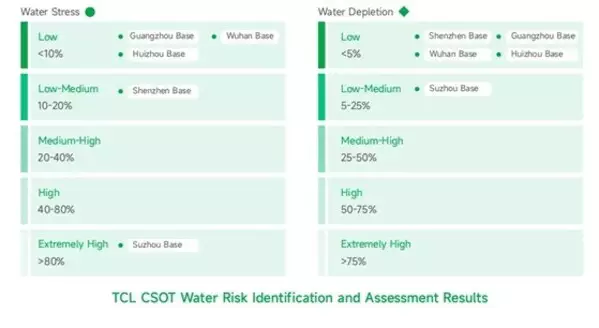

To proactively evaluate and address water-related risks, TCL Technology's subsidiaries employ the World Resources Institute (WRI) Aqueduct Water Risk Atlas to assess water risk levels globally across its factories. For example, TCL CSOT's 2024 assessment identified its Suzhou base as exposed to relatively higher water stress and consumption risks, while other locations reported at medium to low risk levels. These insights inform tailored strategies to mitigate site-specific risks.

Innovating for a Green Future: Clean Technology at the Core of TCL's Strategy

Clean technology is central to TCL Technology's mission of advancing corporate transformation and sustainable growth. By prioritizing investment in clean technologies, the Company integrates sustainability into its business operations, establishing a green management framework that covers the entire product lifecycle and supports global efforts to transition to a low-carbon economy.

In practice, TCL CSOT collaborates with customers to promote circular economy principles, such as recycling and reusing primary packaging materials to reduce resource consumption and environmental impacts. In 2024, the Company completed carbon footprint assessments for its 12.9-inch display panel and 10.1-inch central control display module. Using the results, it optimized key emission hotspots along the product lifecycle and established an ESG-oriented product R&D platform to advance green product development and enhance sustainability performance.

TCL Zhonghuan plays a key role in the energy and low-carbon transition, focusing on reducing the levelized cost of electricity (LCOE) in photovoltaic power systems. Through breakthroughs in photovoltaic wafer and cell technologies, the Company is developing low-emission photovoltaic solar energy products across the full product lifecycle.

By seamlessly integrating water resource efficiency management and clean technology innovation into its operations, TCL Technology is setting a benchmark for sustainable development. The Company's commitment to circular economy principles, resource conservation, and ESG-focused innovation underscores its vision of creating a positive impact on the environment, businesses, and communities worldwide.

###

About TCL

Founded in 1981, TCL—short for "The Creative Life"—embodies creativity in every aspect of life. As a leading technology brand, TCL is dedicated to delivering innovative solutions—including TVs, smartphones, audio products, smart home devices, display technologies, and clean energy—that enhance customer experiences through two independent entities—TCL Industries and TCL Technology.

As of now, with 47 R&D centers and 39 manufacturing bases globally, TCL operates in over 160 countries and regions, cementing its position as a globally competitive smart technology brand. To further inspire greatness, TCL has become an official Worldwide Olympic and Paralympic Partner in the Home Audiovisual Equipment and Home Appliances category.

SHENZHEN, China, Dec. 19, 2025 /PRNewswire/ -- Following the release of its annual ESG report in June 2025, TCL Technology is proud to highlight its progress on water resource protection and green technology innovation, which are key pillars in addressing environmental challenges and building a low-carbon future. TCL Technology prioritizes water resource management and the development of clean technologies as critical components of its strategy to foster green transformation and advance sustainability on a global scale.

Comprehensive Water Resource Management: From Risk Control to Circular Economy

TCL Technology demonstrates its leadership in water resource management through a robust governance framework. The Strategy and Sustainability Committee under the Group's Board of Directors oversees water management strategies and performance, ensuring continuous improvement and adherence to conservation principles across all subsidiaries. By combining sound policies, technological innovation, and comprehensive process control, the Company has built a robust and efficient water resource management system.

TCL Technology embeds water resource management into its corporate governance framework, using policies to guide implementation. For example, TCL CSOT has introduced a Water Resource Management Policy, comprising six sub-policies that outline responsibilities for conservation, resource planning, and inspections. This creates a closed-loop control process from target-setting to implementation and oversight. Similarly, TCL Zhonghuan incorporates water resource management indicators into its ESG performance evaluation framework as part of its Environmental Management Policy, linking plant manager performance to executive remuneration to ensure operational accountability.

Technological innovation and process optimization drive TCL Technology's efforts to use water resources efficiently:

- Guangzhou TCL CSOT: Optimized brine reuse and rainwater collection systems, forming a closed-loop framework covering production, recycling, and reuse.

- Wuhan TCL CSOT: Adopted membrane separation to treat fluoride-bearing wastewater, enabling the reuse of 780,000 cubic meters of water annually. Additional measures, such as chemical precipitation to reduce heavy metals in silver-bearing wastewater and a wetland-based rainwater reuse system, integrate gray infrastructure with ecological solutions.

To proactively evaluate and address water-related risks, TCL Technology's subsidiaries employ the World Resources Institute (WRI) Aqueduct Water Risk Atlas to assess water risk levels globally across its factories. For example, TCL CSOT's 2024 assessment identified its Suzhou base as exposed to relatively higher water stress and consumption risks, while other locations reported at medium to low risk levels. These insights inform tailored strategies to mitigate site-specific risks.

Innovating for a Green Future: Clean Technology at the Core of TCL's Strategy

Clean technology is central to TCL Technology's mission of advancing corporate transformation and sustainable growth. By prioritizing investment in clean technologies, the Company integrates sustainability into its business operations, establishing a green management framework that covers the entire product lifecycle and supports global efforts to transition to a low-carbon economy.

In practice, TCL CSOT collaborates with customers to promote circular economy principles, such as recycling and reusing primary packaging materials to reduce resource consumption and environmental impacts. In 2024, the Company completed carbon footprint assessments for its 12.9-inch display panel and 10.1-inch central control display module. Using the results, it optimized key emission hotspots along the product lifecycle and established an ESG-oriented product R&D platform to advance green product development and enhance sustainability performance.

TCL Zhonghuan plays a key role in the energy and low-carbon transition, focusing on reducing the levelized cost of electricity (LCOE) in photovoltaic power systems. Through breakthroughs in photovoltaic wafer and cell technologies, the Company is developing low-emission photovoltaic solar energy products across the full product lifecycle.

By seamlessly integrating water resource efficiency management and clean technology innovation into its operations, TCL Technology is setting a benchmark for sustainable development. The Company's commitment to circular economy principles, resource conservation, and ESG-focused innovation underscores its vision of creating a positive impact on the environment, businesses, and communities worldwide.

###

About TCL

Founded in 1981, TCL—short for "The Creative Life"—embodies creativity in every aspect of life. As a leading technology brand, TCL is dedicated to delivering innovative solutions—including TVs, smartphones, audio products, smart home devices, display technologies, and clean energy—that enhance customer experiences through two independent entities—TCL Industries and TCL Technology.

As of now, with 47 R&D centers and 39 manufacturing bases globally, TCL operates in over 160 countries and regions, cementing its position as a globally competitive smart technology brand. To further inspire greatness, TCL has become an official Worldwide Olympic and Paralympic Partner in the Home Audiovisual Equipment and Home Appliances category.

** The press release content is from PR Newswire. Bastille Post is not involved in its creation. **

TCL Technology Pioneers a Low-Carbon Future Through Advanced Water Management and Clean Technology Innovation

TCL Technology Pioneers a Low-Carbon Future Through Advanced Water Management and Clean Technology Innovation

TCL Technology Pioneers a Low-Carbon Future Through Advanced Water Management and Clean Technology Innovation

Step Inside 400 Years of Taiko-Making

A 60-Minute "See, Hear, Play" Taiko Experience at Asano Taiko in Hakusan, Ishikawa

KANAZAWA, Japan, Dec. 18, 2025 /PRNewswire/ -- Kanazawa Biyori is a regional media platform that not only introduces the scenery, food, and crafts of Ishikawa, but also focuses on experiences that can only be found in this region. We believe that time spent encountering local skills, sounds, and people leaves a lasting impression on visitors.

Asano Taiko, a Japanese drum manufacturer with over 400 years of history, has recently launched a cultural experience program for domestic and international visitors: "Asano Taiko Factory Tour & Taiko Experience." This 60-minute program combines a factory tour, professional performances, and hands-on drumming sessions, allowing participants to immerse themselves in traditional Japanese taiko culture and craftsmanship through three dimensions: seeing, listening, and playing. Kanazawa Biyori spoke with the organizer about this unique program.

Visiting a Taiko Workshop with Over 400 Years of History

Asano Taiko traces its roots back to an early Edo-period family craft business and has passed down taiko-making skills for more than four centuries. At the 2010 NAMM Show—one of the world's largest musical instrument trade fairs—the company was recognized as the oldest percussion manufacturer in the industry.

From selecting and hollowing logs, to shaping and lacquering the body, stretching the hides, and securing them with tacks, Asano Taiko carries out all stages of taiko production in its own workshops. In particular, the company is known for its large drums over three shaku (approx. 90 cm) in diameter, which hold a top-class share of the domestic market.

The tour begins in the showroom, where visitors can see a variety of instruments up close—ōdaiko (large drums), miya-daiko, tsuzumi, and different types of bachi (drumsticks). Highlights include a 6-shaku-1-sun ōdaiko (approx. 185 cm head diameter, weighing over one ton) and Asano's original tunable oke-daiko. Guests are welcome to try striking some of the drums to hear their sound.

After that, participants move into the normally closed factory area to observe artisans at work. The quiet concentration of craftspeople facing wood and hide, and the repetition of each careful step, reveal how a single stroke on the drum is supported by a long chain of manual processes.

From Professional Performance to Your Own "First Strike"

Following the factory tour, the program moves to Asano Taiko's in-house studio. A professional taiko performer, who also serves as instructor, presents a solo performance on the ōdaiko. Each stroke sends vibrations through the air and into the listener's body, conveying the expressive range of taiko—built only from rhythm, dynamics, and tempo.

Participants then pick up bachi themselves and receive simple instruction on how to play. During our visit, overseas travelers joined the session as well. Starting from basic patterns and gradually moving to more complex rhythms, their expressions and the sound of their playing grew more confident with each phrase. Regardless of language or cultural background, sharing rhythm together naturally brought smiles to the group.

Why Kanazawa Biyori Is Paying Attention

1. An integrated "factory × performance × hands-on" cultural experience

Rather than being only a factory tour or a casual workshop, this program deliberately weaves together three elements:

- Learning about the history of a long-established maker and its production process

- Feeling the sound of taiko through a professional performance

- Experiencing the act of drumming with your own hands

This structure gives the tour a high degree of completeness as a cultural experience, suitable for both first-time visitors and those already familiar with taiko.

2. Small groups, private bookings, and flexible for all ages and backgrounds

The tour is offered for groups of 2 to 20 people, with each time slot reserved for a single group. There is no strict age limit, making it possible for children and older adults to participate together. The program has already welcomed international visitors and can be adapted for family trips, school excursions, and corporate training.

3. A manageable excursion from Kanazawa with strong regional character

Asano Taiko is located in Fukutome-machi, Hakusan City—an area that is easy to access from central Kanazawa:

- Around 40 minutes by car from Komatsu Airport

- Around 8 minutes by car from Matto Station on the IR Ishikawa Railway

For travelers visiting Ishikawa, it works well as a half-day excursion that adds a "behind-the-scenes" craft experience to itineraries focused on Kanazawa's well-known sightseeing spots.

Tour Overview

Name: Asano Taiko Factory Tour & Taiko Experience (Approx. 60 minutes)

Location:

Asano Taiko Co., Ltd.

587-1 Fukutome-machi, Hakusan City, Ishikawa Prefecture, Japan

(Approx. 40 minutes by car from Komatsu Airport / 8 minutes by car from Matto Station)

Program Content (Total 60 minutes):

Fee: ¥3,000 per person (tax included)

Reservations accepted from two participants and up.

Available Hours: Weekdays, 10:00 AM – 3:00 PM

Closed: Saturdays, Sundays, public holidays, Obon, and year-end/New Year holidays

Group Size: 2–20 people (one private group per time slot)

Reservations:

Advance booking required at least two weeks before the desired date.

Please apply by phone or via the inquiry form on the website.

*An English-language pamphlet for the factory tour is available; however, on-site interpretation in English is not provided.

Tour Inquiries (Content & Booking):

Asano Taiko Co., Ltd. – Factory Tour & Experience Desk

Tel: +81-76-277-1717 (main)

Phone hours: Weekdays 8:30 AM–5:30 PM / Weekends & holidays 10:00 AM–4:00 PM

Official website (tour details):

https://www.asano.jp/

Media Contact for This Release

Kanazawa Biyori Co., Ltd.

Sunpia Izumigaoka 511, 255 Fushimishinmachi, Kanazawa, Ishikawa Prefecture, Japan

Email: info@kanazawabiyori.com

** The press release content is from PR Newswire. Bastille Post is not involved in its creation. **

Asano Taiko Factory Tour & Taiko Experience (Ishikawa, Japan)