As China and Chile celebrate the 55th anniversary of the establishment of diplomatic relations between the two countries, Chilean Ambassador to China Pablo Arriaran has offered a comprehensive assessment of bilateral ties, highlighting not only the rapid growth in trade but also expectations for future more in-depth cooperation in renewable energy, clean technology and artificial intelligence.

"I believe that being among the pioneers in establishing ties, and later formalizing diplomatic relations with China allowed the Chinese government to develop a special perspective on our country, which ultimately has led to a closer relationship,” Arriaran said, referring to the fact that Chile was the first South American country to establish diplomatic relations with the People's Republic of China.

The ambassador also reviewed the most significant milestones over the past 55 years since the establishment of diplomatic relations between China and Chile on December 15, 1970.

"I think the most important milestone was the signing of the Free Trade Agreement in 2005, because of the impact it has had on our economy. It has been a very beneficial trade agreement for both sides. In our case, it helped increase total trade with China from just over 6 billion U.S. dollars to nearly 60 billion,” he said.

Looking ahead, the ambassador emphasized the potential for expanded cooperation in renewable energy, clean technology and artificial intelligence.

"Looking to the future, over a five-year horizon, beyond continued growth in trade in both directions, I believe there is considerable room for cooperation in specific sectors such as renewable energy, clean technologies, sustainable infrastructure and artificial intelligence. In all these areas, there is space for cooperation between our two countries -- not only at the government level -- to grow stronger and to be channeled into sectors where engagement is not yet as intensive,” he said.

Chilean ambassador to China summarizes milestones in bilateral ties, expects broader, more in-depth cooperation

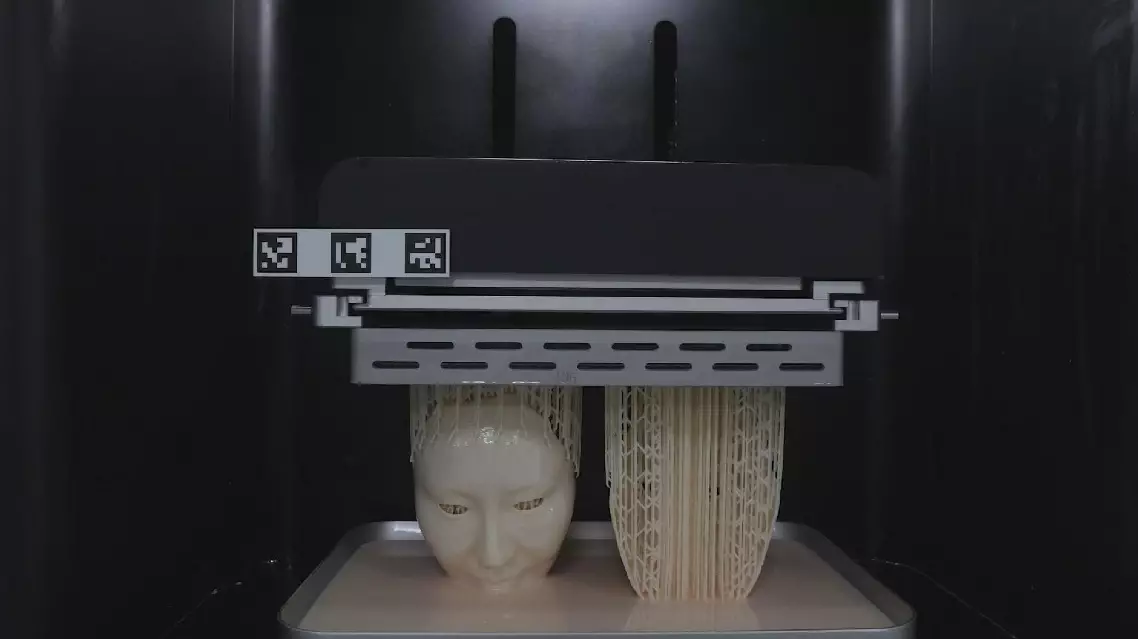

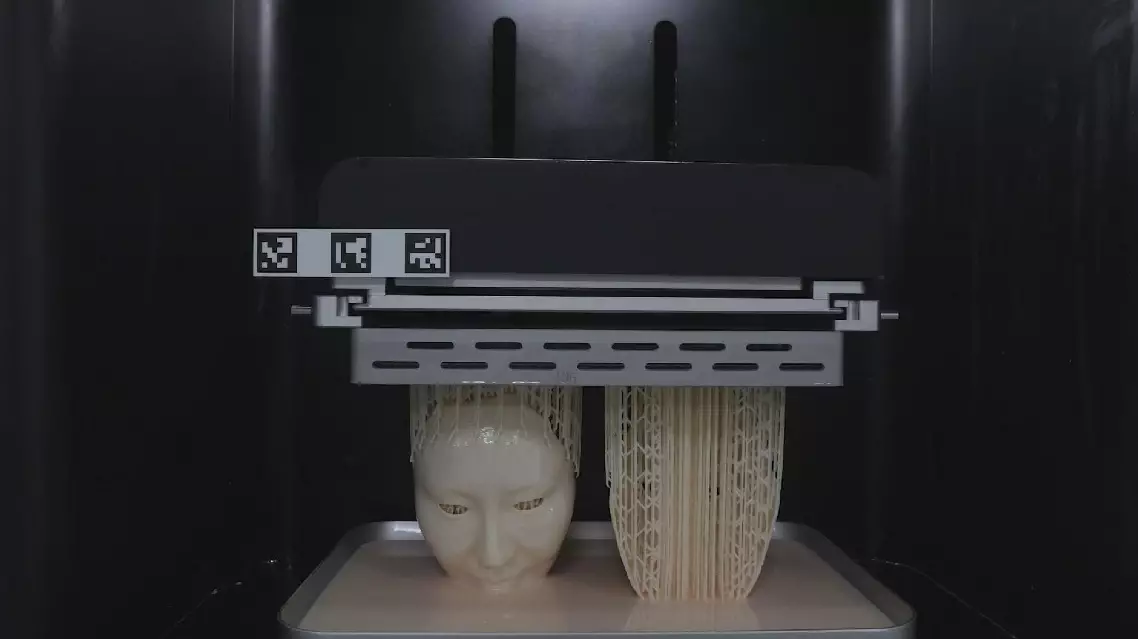

From everyday objects to fiber-type artificial muscles for robotic actuation, a groundbreaking photopolymerization-based 3D printing technology is playing a role in revolutionizing how we create, representing a fundamental shift from traditional methods and transforming industries and daily life.

Distinct from conventional layer-by-layer material deposition, the new technology employs light as a precision actuator. The process begins with instillation of liquid photopolymer resin that instantly solidifies when exposed to targeted ultraviolet (UV) light, which acts as an "on-off switch" for material formation.

Unlike traditional drying methods that rely on heat and air, UV curing employs specific wavelengths of UV light to achieve rapid and controlled polymerization.

This enables the material to reach its desired mechanical properties in a fraction of the time that other methods might require -- 20 to 100 times faster than traditional 3D printing -- allowing complete products to be created within just two to three hours.

At PollyPolymer -- a high-tech enterprise specializing in ultra-high-speed 3D printing technology based in Suzhou City of east China's Jiangsu Province, the technique has been hired to produce customized components, such as elastomer artificial muscles for robots that combine flexibility with durability.

"(This material) can provide shock absorption and protection. Additionally, due to its hollowed-out lattice structure, it can dissipate heat. Of course, another advantage is its lightweight nature, as it is filled with many lattices within the same structure," Wang Wenbin, the company's CEO, introduced.

More importantly, these materials can be pre-programmed and engineered to meet specific structural, elastic and mechanical performance requirements, enabling on-demand and customized manufacturing across multiple industries, Wang said, noting that precision control remains crucial to the process.

"We need very precise control because the light reaction can cause many falsifications such as distortion, leading to a decrease in accuracy. Therefore, we have designed quite a lot of algorithmic compensations in this process. Each printer has a force sensing parameter, which you can think of as a scale that knows the weight in every gram and makes corrections accordingly. Depending on the required scenario, for instance, our highest precision can now reach 2.8 microns," Wang said.

3D printing ushers in new era of instant manufacturing