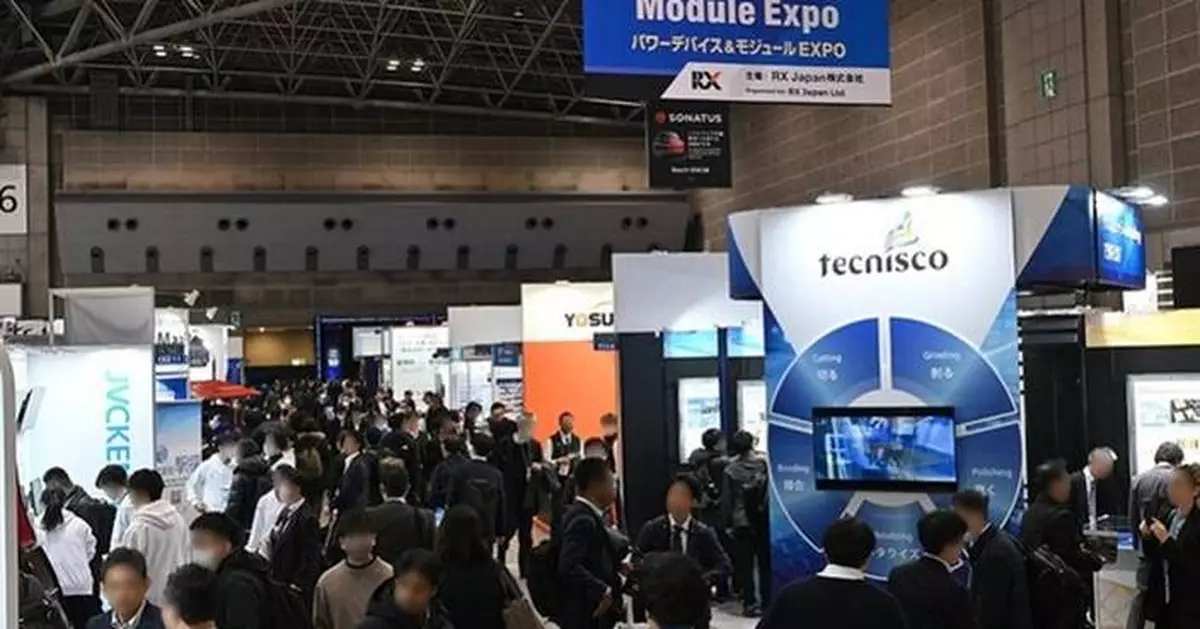

TOKYO, Jan. 16, 2026 /PRNewswire/ -- RX Japan is all set to host the 40th edition of NEPCON JAPAN, one of the world's leading technology trade shows, from January 21–23, 2026, at Tokyo Big Sight. This milestone event will be held alongside three major exhibitions — AUTOMOTIVE WORLD, Factory Innovation Week, and Smart Logistics Expo — creating one of Asia's largest technology gatherings.

The combined shows are expected to feature 1,850 exhibitors and attract 92,000 visitors, offering an unparalleled platform for professionals across electronics, automotive, manufacturing, and logistics sectors.

In addition, more than 200 technical seminars will take place during the three-day event, delivering insights from industry leaders such as Dr. Rao R. Tummala (Emeritus Professor, Georgia Institute of Technology/Advisor of Indian Semiconductor Mission, Government of India) and leading global companies such as Rapidus Corp., ASE (Advanced Semiconductor Engineering, Inc. ), Intel, Infineon Technologies Japan, StarPower Semiconductor, Resonac Corp., and TSMC Japan 3DIC R&D Center Inc.

NEPCON JAPAN has been recognised for four decades as a comprehensive showcase for innovations in electronics manufacturing, semiconductors, and advanced packaging technologies. For its 40th anniversary edition, the exhibition will span the entire Tokyo Big Sight venue, providing attendees with expanded opportunities to explore cutting-edge solutions and network with industry pioneers.

"The 40th year of NEPCON JAPAN will be a grand celebration of the global electronics industry that it has grown alongside. With over 1,850 exhibitors from all over the world, the three-day event will serve as a massive showcase of R&D, manufacturing, and packaging technologies, alongside its co-located shows," said Masaki Soda, Show Director.

Free visitor registration for NEPCON JAPAN is now open at: https://x.gd/zUXbQ

For more details and updates, visit the official website: https://www.nepconjapan.jp/tokyo/en-gb.html.

Contact:

TEL: +81-3-6739-4102

E-mail: inw.jp@rxglobal.com

Web: https://www.nepconjapan.jp/tokyo/en-gb.html

About RX Japan GK

RX Japan GK organises 106 exhibitions, composed of 415 sub-exhibitions, annually at large exhibition halls such as Tokyo Big Sight, Makuhari Messe, and INTEX Osaka across a wide variety of 38 fields, including jewellery, fashion, gift items, electronics, energy, IT, cosmetics, and medical. Visit the RX Japan website for more details.

** The press release content is from PR Newswire. Bastille Post is not involved in its creation. **

NEPCON JAPAN Opens Next Week at Tokyo Big Sight with 1,850 Exhibitors, Marking its 40th Anniversary

|

CHONGQING, China, Jan. 16, 2026 /PRNewswire/ -- The World Economic Forum (WEF) recently announced the latest members of its Global Lighthouse Networks 2026, with HiTHIUM's Chongqing manufacturing base successfully selected. The factory becomes the world's first Lighthouse Factory for energy storage batteries, marking a major milestone for the global energy storage industry.

The factory is also the world's first mass-production facility dedicated to kAh long-duration energy storage (LDES) battery. Through systematic breakthroughs in intelligent manufacturing and digital transformation, the Chongqing manufacturing base sets a new benchmark for high-quality development across the global energy storage value chain.

The Global Lighthouse Network is a World Economic Forum initiative recognizing best-in-class operational sites and value chains that have achieved exceptional performance in productivity, supply chain resilience, customer centricity, sustainability and talent. The initiative was co-founded with McKinsey & Company and is counselled by an advisory board of industry leaders working together to shape the future of global manufacturing. As of today, 224 Lighthouse Factories have been recognized globally, with HiTHIUM being the first to represent the energy storage battery sector.

"Competitiveness today is no longer defined by efficiency alone, but by the ability to sense, adapt and respond at speed," said Kiva Allgood, Managing Director, World Economic Forum. "This year's industrial transformation sites show how intelligence-led operations are being scaled to place resilience and sustainability at the core of how industry operates."

A "Thinking" Factory Redefining Energy Storage Manufacturing

As lithium-ion energy storage plays an increasingly vital role in renewable energy integration and grid stability, the industry is experiencing rapid growth alongside mounting challenges. These include surging demand, intensified cost pressures, and increasingly stringent requirements for battery consistency. Traditional manufacturing models are no longer sufficient to meet these demands.

In response, HiTHIUM's Chongqing manufacturing base has advanced a comprehensive intelligent manufacturing strategy focused on near-zero-defect production, systematic cost optimization, and intelligent operations. Through continuous exploration of lean production and advanced manufacturing practices, the base has achieved significant improvements in yield, production capacity, and overall equipment effectiveness.

At the core of HiTHIUM's intelligent manufacturing approach is a factory that can truly "think." The Chongqing manufacturing base has deployed more than 40 digital solutions, deeply integrating generative artificial intelligence, machine learning, and AIoT technologies. These innovations enable full-lifecycle intelligent control spanning R&D, material selection, manufacturing, and final inspection. By establishing a closed-loop, data-driven management system across the entire production chain, the base ensures exceptional product consistency, laying a solid foundation for high safety, reliability, and performance in energy storage batteries.

Forward-Looking Deployment to Lead LDES

Building on the growing maturity of its intelligent manufacturing system, HiTHIUM continues to advance forward-looking production layouts tailored specifically for LDES applications. The Chongqing manufacturing base has steadily expanded the adaptability of intelligent manufacturing across different technical pathways and application scenarios, reinforcing its role in supporting the industrialization of LDES.

The base has also established the world's first production line dedicated to LDES batteries. In June 2025, HiTHIUM's ∞Cell 1175Ah LDES battery entered mass production. In October, the ∞Power 6.25MWh 4h LDES BESS, powered by this battery, began global deliveries. In December, the system was selected as the sole representative from the energy storage sector at a national-level exhibition highlighting advancements in Chinese manufacturing.

Looking ahead, HiTHIUM will further leverage the lighthouse factory's demonstrative role in intelligent R&D, smart manufacturing, and the development of agile and resilient supply chain networks. As an industry chain leader, the company will also drive digital transformation across upstream and downstream partners, fostering a highly collaborative and efficient industrial ecosystem.

By continuously exporting scalable intelligent manufacturing practices and industrialization capabilities, HiTHIUM aims to support the large-scale, high-quality, safe, and efficient deployment of LDES batteries and systems—contributing a robust Chinese solution to the global transition toward green and sustainable energy.

CHONGQING, China, Jan. 16, 2026 /PRNewswire/ -- The World Economic Forum (WEF) recently announced the latest members of its Global Lighthouse Networks 2026, with HiTHIUM's Chongqing manufacturing base successfully selected. The factory becomes the world's first Lighthouse Factory for energy storage batteries, marking a major milestone for the global energy storage industry.

The factory is also the world's first mass-production facility dedicated to kAh long-duration energy storage (LDES) battery. Through systematic breakthroughs in intelligent manufacturing and digital transformation, the Chongqing manufacturing base sets a new benchmark for high-quality development across the global energy storage value chain.

The Global Lighthouse Network is a World Economic Forum initiative recognizing best-in-class operational sites and value chains that have achieved exceptional performance in productivity, supply chain resilience, customer centricity, sustainability and talent. The initiative was co-founded with McKinsey & Company and is counselled by an advisory board of industry leaders working together to shape the future of global manufacturing. As of today, 224 Lighthouse Factories have been recognized globally, with HiTHIUM being the first to represent the energy storage battery sector.

"Competitiveness today is no longer defined by efficiency alone, but by the ability to sense, adapt and respond at speed," said Kiva Allgood, Managing Director, World Economic Forum. "This year's industrial transformation sites show how intelligence-led operations are being scaled to place resilience and sustainability at the core of how industry operates."

A "Thinking" Factory Redefining Energy Storage Manufacturing

As lithium-ion energy storage plays an increasingly vital role in renewable energy integration and grid stability, the industry is experiencing rapid growth alongside mounting challenges. These include surging demand, intensified cost pressures, and increasingly stringent requirements for battery consistency. Traditional manufacturing models are no longer sufficient to meet these demands.

In response, HiTHIUM's Chongqing manufacturing base has advanced a comprehensive intelligent manufacturing strategy focused on near-zero-defect production, systematic cost optimization, and intelligent operations. Through continuous exploration of lean production and advanced manufacturing practices, the base has achieved significant improvements in yield, production capacity, and overall equipment effectiveness.

At the core of HiTHIUM's intelligent manufacturing approach is a factory that can truly "think." The Chongqing manufacturing base has deployed more than 40 digital solutions, deeply integrating generative artificial intelligence, machine learning, and AIoT technologies. These innovations enable full-lifecycle intelligent control spanning R&D, material selection, manufacturing, and final inspection. By establishing a closed-loop, data-driven management system across the entire production chain, the base ensures exceptional product consistency, laying a solid foundation for high safety, reliability, and performance in energy storage batteries.

Forward-Looking Deployment to Lead LDES

Building on the growing maturity of its intelligent manufacturing system, HiTHIUM continues to advance forward-looking production layouts tailored specifically for LDES applications. The Chongqing manufacturing base has steadily expanded the adaptability of intelligent manufacturing across different technical pathways and application scenarios, reinforcing its role in supporting the industrialization of LDES.

The base has also established the world's first production line dedicated to LDES batteries. In June 2025, HiTHIUM's ∞Cell 1175Ah LDES battery entered mass production. In October, the ∞Power 6.25MWh 4h LDES BESS, powered by this battery, began global deliveries. In December, the system was selected as the sole representative from the energy storage sector at a national-level exhibition highlighting advancements in Chinese manufacturing.

Looking ahead, HiTHIUM will further leverage the lighthouse factory's demonstrative role in intelligent R&D, smart manufacturing, and the development of agile and resilient supply chain networks. As an industry chain leader, the company will also drive digital transformation across upstream and downstream partners, fostering a highly collaborative and efficient industrial ecosystem.

By continuously exporting scalable intelligent manufacturing practices and industrialization capabilities, HiTHIUM aims to support the large-scale, high-quality, safe, and efficient deployment of LDES batteries and systems—contributing a robust Chinese solution to the global transition toward green and sustainable energy.

** The press release content is from PR Newswire. Bastille Post is not involved in its creation. **

HiTHIUM Recognized as the World's First Lighthouse Factory for Energy Storage Batteries