HONG KONG, Feb. 9, 2026 /PRNewswire/ -- To inspire students in Hong Kong and the Greater Bay Area (GBA), unleash their creativity, and engage with the evolving landscape of new media, the Department of Marketing and International Business at Lingnan University organised The City Through My Lens: A Social Media Campaign - Video Competition 2025. Students were invited to form teams and create short promotional social media videos capturing the highlights of their cities. The competition provided a platform for GBA secondary school students to express their creativity and broaden their horizons, while also strengthening the connection between the University and the younger generation. This is the first time the competition has included schools across the GBA, and there were 18 entrants. The championship was awarded to Malvern College Hong Kong, the first runner-up was St. Paul's Convent School, and the other runners-up were the HKSYC&IA Chan Nam Chong Memorial College, Sha Tin College, St. Paul's Secondary School and Yew Chung International School.

The awards ceremony was held on 7 February, and Prof Patrick Poon Shing-chung, Associate Dean (Undergraduate Studies and AACSB) of Faculty of Business of Lingnan University, congratulated all the winning teams in his welcoming speech, saying "The videos submitted by the students convey the creativity and inventive spirit of the new generation. Many of them incorporate technology and AI elements, and use the latest tools to raise production quality, reflecting the students' abilities in research and practice. This aligns with Lingnan University's philosophy of holistic education, emphasising interdisciplinary practice, and combining technology and innovation with a humanistic perspective. The University is dedicated to cultivating students' natural aptitude to meet the demands of the future, and the work submitted indicates that they already have the potential for interdisciplinary modernisation."

All the teams were asked to produce a video of no more than three minutes based on an original story, presenting the city from their perspective. If AI tools were used, students were required to specify which, and how they were used. The judging panel of professors from the Department of Marketing and International Business assessed the entries on their relevance to theme, creativity, and technical execution.

The judging panel praised the 18 videos for their artistic imagination and depth. Various filming techniques including aerial shots were used, and good editing enhanced the overall quality, demonstrating the technological and original talents of the younger generation in the digital age.

After several rounds of viewing and marking, the video from Malvern College Hong Kong emerged as the best, and won a prize of HK$5,000. The video shows the wonderful journey of a girl exploring Hong Kong's multiculturalism in her dreams: visiting various districts, including bustling Hong Kong Island, the Chinese-inspired Lingnan Garden in Lai Chi Kok, the arts and culture hub in West Kowloon, and the diverse district of Mong Kok. The video captures Hong Kong's unique characteristics, featuring the city's charm and blending Eastern and Western cultures seamlessly.

Delighted, the winning team said "We are grateful to the staff at Lingnan University for their guidance throughout the competition. We faced challenges both large and small, from capturing Hong Kong authentically to managing heavy video files, but our perseverance and teamwork helped to create a video that showcases the city through our unique lens."

Prof Peng Ling, Head of the Department of Marketing and International Business, said "The Lingnan Faculty of Business hopes that this competition will demonstrate the University's teaching characteristics in the integration of the arts and sciences, nurturing students with literacy knowledge, practical competence, and the ability to think critically. We believe that the creativity, communication skills, and spirit of teamwork demonstrated by students in this competition will lay a valuable foundation for their future studies and careers."

To instruct students in filming and editing techniques, the Department of Marketing and International Business organised a pre-competition "Workshop for Secondary School Students: AI-powered Video Editing (for Beginners)". Led by Prof Qi Suntong, Assistant Professor of the Department of Marketing and International Business, the workshop coached students in the newest AI tools for image, video, voice-over, and music creation, as well as in practical scriptwriting, storyboard design, and film production with cinematic qualities. Students learnt how to use the tools to enhance their storytelling, and also displayed their work and held discussions during the workshop, which inspired them, and encouraged them to use technology skilfully and correctly in both the competition and their future studies.

For award details, please visit: https://www.ln.edu.hk/mkt/lumsm-2025/award-winners.

** The press release content is from PR Newswire. Bastille Post is not involved in its creation. **

Lingnan University hosts "The City Through My Lens: A Social Media Campaign - Video Competition" with an AI training workshop for 18 secondary school teams from Hong Kong and the Greater Bay Area

|

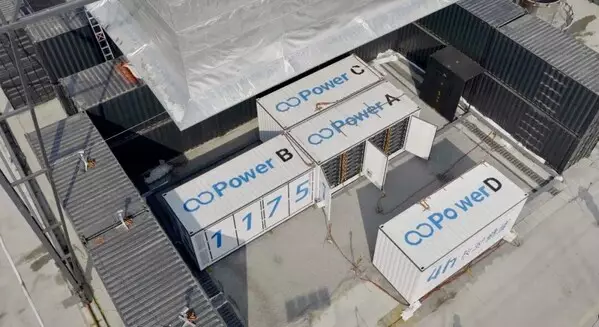

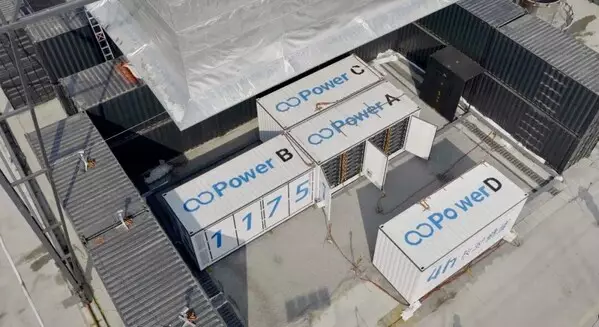

XIAMEN, China, Feb. 9, 2026 /PRNewswire/ -- Recently, HiTHIUM completed the world's first open-door large-scale fire test of its ∞Power 6.25MWh 4h long-duration energy storage (LDES) system equipped with kiloampere-hour (kAh) battery cells. The test was conducted under the full supervision of representatives from UL Solutions, U.S. Authorities Having Jurisdiction, and Fire Protection Engineers. The test strictly complied with the latest requirements of UL 9540A 2025 and NFPA 855-2026.

The test results demonstrate that the high-energy-density 6.25MWh energy storage system, incorporating ultra-large-capacity battery cells, exhibited stable and controllable safety performance under extreme conditions. This marks a critical breakthrough in safety validation at higher energy levels for LDES systems, further strengthening the safety foundation for large-scale industry deployment.

Extreme Real-World Scenarios: Confronting Safety Limits at Higher Energy Levels

Building on its previous open-door fire test of a 5MWh system, HiTHIUM conducted an upgraded validation focusing on the ∞Power 6.25MWh LDES system and its core ∞Cell 1175Ah, verifying system-level safety at significantly higher energy levels.

The test was conducted under the most stringent conditions: the container doors remained fully open throughout the test creating an "open-door combustion" condition to maximize oxygen supply and flame impact; adjacent containers were arranged back-to-back and side-by-side with only 15 cm spacing; the system operated at 100% state of charge; and all active fire suppression systems were disabled, relying solely on intrinsic safety design.

Three Core Safety Challenges: Comprehensive Validation of a Multi-Layer Protection System

To address the compounded risks introduced by ultra-large-capacity cells and high-energy-density systems, HiTHIUM implemented a multi-layer safety architecture spanning the cell, module, and system levels. Guided by the core technical approach of "release, protection, and resistance," the test validated the three core safety challenges.

Release Without Explosion: Precise Management of Ultra-High Energy Release

To manage the massive energy release during thermal runaway of 1175Ah cells, HiTHIUM designed a three-dimensional airflow channel with directional venting, and the module adopted a dual pressure relief valve safety design. This structure enabled rapid and controlled gas release at the cell and module levels, preventing explosive pressure buildup. No explosions or debris ejection were observed during the test.

Combustion Without Propagation: Dual Physical Barriers Against Thermal Spread

Under the most severe conditions of open-door combustion and minimal spacing conditions, the system endured direct flame exposure and intense heat transfer. Fire-resistant module covers, reinforced steel enclosures, and insulated multi-layer container structures confined the fire to a single battery system with no thermal propagation across the containers, and temperatures of cells in adjacent containers remained below safety thresholds.

Resistance Without Structural Failure: Structural Stability Under Extreme Thermal Stress

To withstand prolonged high-temperature exposure, the ∞Power 6.25MWh system was structurally reinforced with a high-strength steel frame, stiffeners, and dual-layer partitions. After continuous combustion, the affected container remained structurally intact, with no significant deformation or collapse observed.

A Milestone Achievement: Redefining Safety Standards for LDES

This test systematically verified the overall safety performance of the ∞Power 6.25MWh LDES system equipped with kAh battery cells, representing a milestone within the global energy storage safety validation framework.

As system capacity continues to increase from 5MWh to 6.25MWh, HiTHIUM remains committed to advancing safety and reliability through rigorous design standards and extreme-condition testing.

Looking ahead, HiTHIUM will remain focused on LDES as a strategic priority, further strengthening its safety foundation and core technologies. By participating in the development of global energy storage safety frameworks to higher standards, and working closely with industry partners, HiTHIUM aims to drive LDES toward larger scale, higher reliability, and safer, more efficient deployment —supporting a steady and sustainable global energy transition.

XIAMEN, China, Feb. 9, 2026 /PRNewswire/ -- Recently, HiTHIUM completed the world's first open-door large-scale fire test of its ∞Power 6.25MWh 4h long-duration energy storage (LDES) system equipped with kiloampere-hour (kAh) battery cells. The test was conducted under the full supervision of representatives from UL Solutions, U.S. Authorities Having Jurisdiction, and Fire Protection Engineers. The test strictly complied with the latest requirements of UL 9540A 2025 and NFPA 855-2026.

The test results demonstrate that the high-energy-density 6.25MWh energy storage system, incorporating ultra-large-capacity battery cells, exhibited stable and controllable safety performance under extreme conditions. This marks a critical breakthrough in safety validation at higher energy levels for LDES systems, further strengthening the safety foundation for large-scale industry deployment.

Extreme Real-World Scenarios: Confronting Safety Limits at Higher Energy Levels

Building on its previous open-door fire test of a 5MWh system, HiTHIUM conducted an upgraded validation focusing on the ∞Power 6.25MWh LDES system and its core ∞Cell 1175Ah, verifying system-level safety at significantly higher energy levels.

The test was conducted under the most stringent conditions: the container doors remained fully open throughout the test creating an "open-door combustion" condition to maximize oxygen supply and flame impact; adjacent containers were arranged back-to-back and side-by-side with only 15 cm spacing; the system operated at 100% state of charge; and all active fire suppression systems were disabled, relying solely on intrinsic safety design.

Three Core Safety Challenges: Comprehensive Validation of a Multi-Layer Protection System

To address the compounded risks introduced by ultra-large-capacity cells and high-energy-density systems, HiTHIUM implemented a multi-layer safety architecture spanning the cell, module, and system levels. Guided by the core technical approach of "release, protection, and resistance," the test validated the three core safety challenges.

Release Without Explosion: Precise Management of Ultra-High Energy Release

To manage the massive energy release during thermal runaway of 1175Ah cells, HiTHIUM designed a three-dimensional airflow channel with directional venting, and the module adopted a dual pressure relief valve safety design. This structure enabled rapid and controlled gas release at the cell and module levels, preventing explosive pressure buildup. No explosions or debris ejection were observed during the test.

Combustion Without Propagation: Dual Physical Barriers Against Thermal Spread

Under the most severe conditions of open-door combustion and minimal spacing conditions, the system endured direct flame exposure and intense heat transfer. Fire-resistant module covers, reinforced steel enclosures, and insulated multi-layer container structures confined the fire to a single battery system with no thermal propagation across the containers, and temperatures of cells in adjacent containers remained below safety thresholds.

Resistance Without Structural Failure: Structural Stability Under Extreme Thermal Stress

To withstand prolonged high-temperature exposure, the ∞Power 6.25MWh system was structurally reinforced with a high-strength steel frame, stiffeners, and dual-layer partitions. After continuous combustion, the affected container remained structurally intact, with no significant deformation or collapse observed.

A Milestone Achievement: Redefining Safety Standards for LDES

This test systematically verified the overall safety performance of the ∞Power 6.25MWh LDES system equipped with kAh battery cells, representing a milestone within the global energy storage safety validation framework.

As system capacity continues to increase from 5MWh to 6.25MWh, HiTHIUM remains committed to advancing safety and reliability through rigorous design standards and extreme-condition testing.

Looking ahead, HiTHIUM will remain focused on LDES as a strategic priority, further strengthening its safety foundation and core technologies. By participating in the development of global energy storage safety frameworks to higher standards, and working closely with industry partners, HiTHIUM aims to drive LDES toward larger scale, higher reliability, and safer, more efficient deployment —supporting a steady and sustainable global energy transition.

** The press release content is from PR Newswire. Bastille Post is not involved in its creation. **

HiTHIUM Completes World's First Open-Door Large-Scale Fire Test of a 6.25MWh BESS with kAh Battery Cells