As the global electric vehicle (EV) market and renewable energy sector continue to expand rapidly, demand for advanced lithium-ion battery technology continues to grow. A research team from City University of Hong Kong (CityUHK) has been awarded funding under the “RAISe+ Scheme” to address the long-standing voltage decay issue associated with lithium-rich cathode materials. This groundbreaking research aims to introduce a new range of battery materials that offer enhanced energy density, extended lifespan and reduced costs.

The project plans to build a 1,000-ton materials production line and is expected to create approximately 100 new jobs.

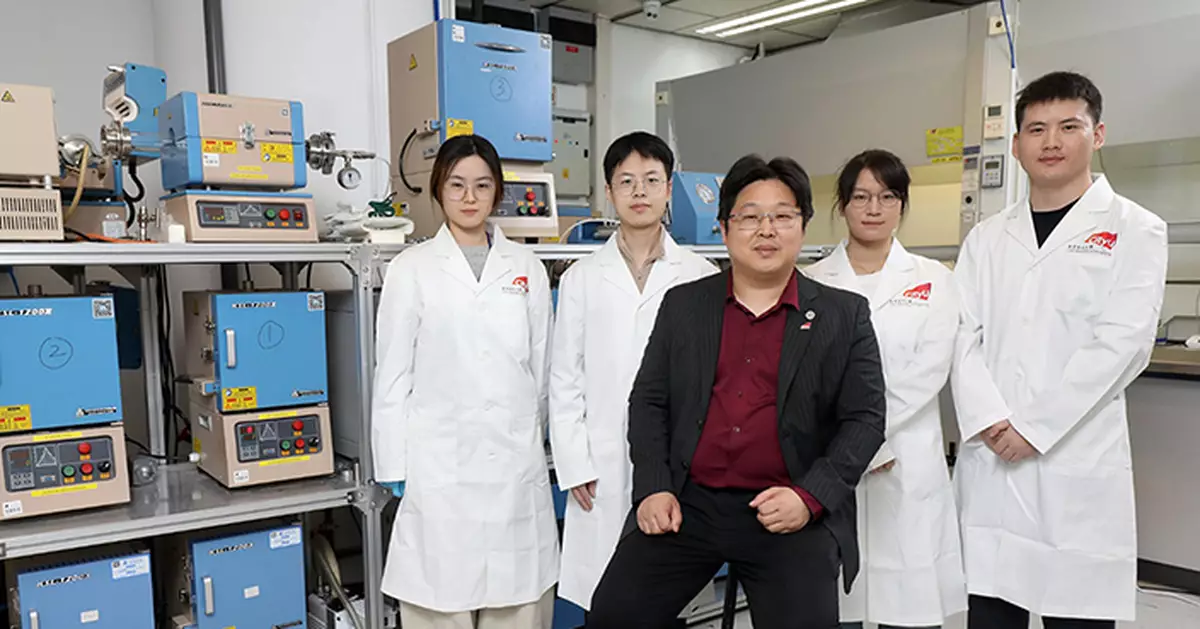

Led by Professor Liu Qi (centre), from the Department of Physics at CityUHK, the project, titled “Breakthrough Cathode Materials for Next-generation Lithium-ion Batteries”, has been awarded funding under the “RAISe+ Scheme”. Photo credit: City University of Hong Kong

Led by Professor Liu Qi, from the Department of Physics at CityUHK, the project is titled “Breakthrough Cathode Materials for Next-generation Lithium-ion Batteries”. With the support of the “RAISe+ Scheme”, launched by the Government of the Hong Kong Special Administrative Region of the People’s Republic of China, the team aims to transform this technological breakthrough into industrial-scale applications within three years and optimise the production line for next-generation output.

Lithium-ion batteries (LIBs) have become a cornerstone of the global energy transition, playing an essential role in renewable energy storage systems and smart technologies – from mobile phones to the EV revolution and large-scale solar power stations. With the rapid growth in global demand, the LIB market is projected to reach US$150 billion by 2030, with over US$60 billion coming from cathode materials, the component that contributes most significantly to the overall cost of batteries.

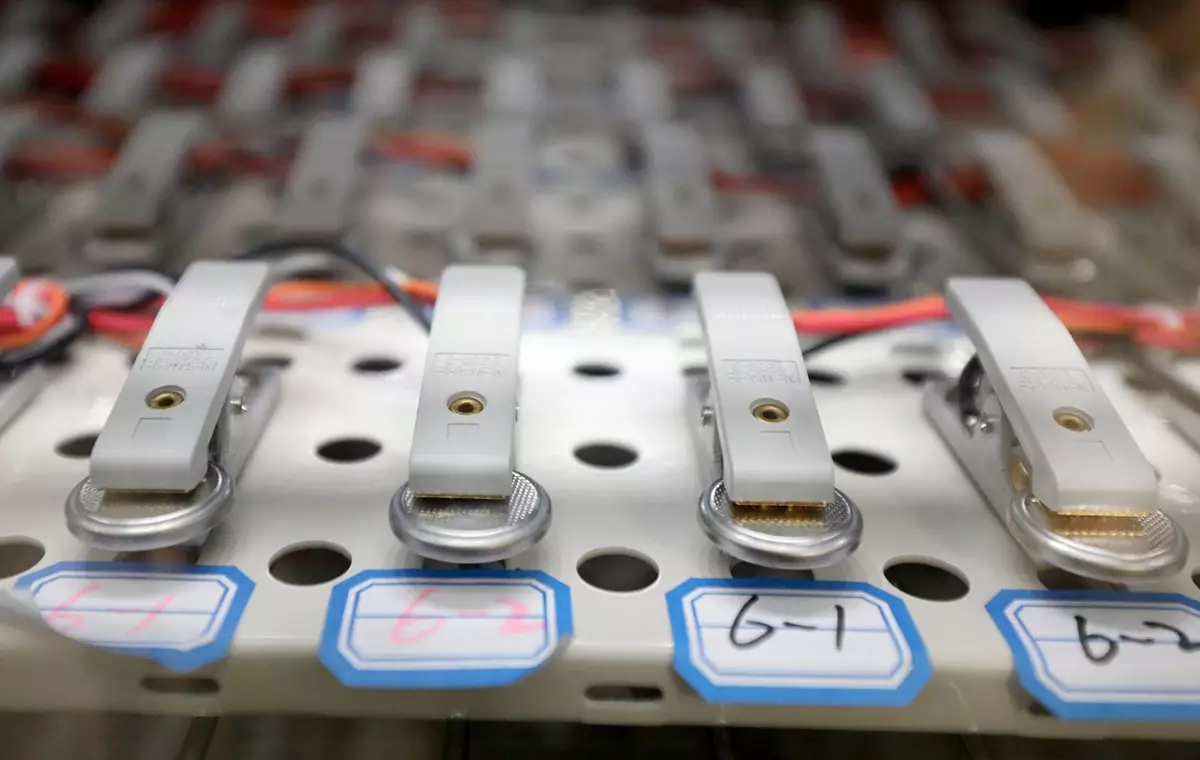

Among various cathode materials, lithium-rich layered oxides (LLOs) stand out for their high capacity, high operating voltage and cost advantages due to abundant raw materials. They are widely regarded as the “ultimate cathode material”, capable of significantly enhancing the performance of lithium-ion batteries.

Despite their theoretical advantages, however, LLOs face critical challenges of voltage and capacity decay, which have long hindered their commercialisation.

Lithium-rich layered oxides (LLOs) are widely regarded as the “ultimate cathode material for lithium-ion batteries”. Photo credit: City University of Hong Kong

The team’s innovative approach focuses on stabilising the honeycomb structure by incorporating additional transition metal (TM) ions into the cathode material. This modification suppresses oxygen release, cation migration and structural degradation, effectively addressing the core issue of voltage decay. This sets a new benchmark for high-performance LLOs and provides a solid foundation for industrialisation.

Furthermore, the team employs advanced surface engineering techniques to tackle capacity decay caused by surficial degradation, TM ion dissolution, structural deterioration and electrolyte corrosion. The team introduced protective agents, such as carbon coating layers, during the calcination process. This protective layer ensures long-term stability, marking a significant step in energy storage technology.

These groundbreaking technologies were published in Nature Energy in 2023. Building on these laboratory breakthroughs, the team aims to accelerate the commercialisation process by focusing on the development of two product lines: 1) LLOs for traditional LIBs, aiming to increase the energy density of traditional LIBs by over 30%, while reducing costs; and 2) LLOs for solid-state batteries.

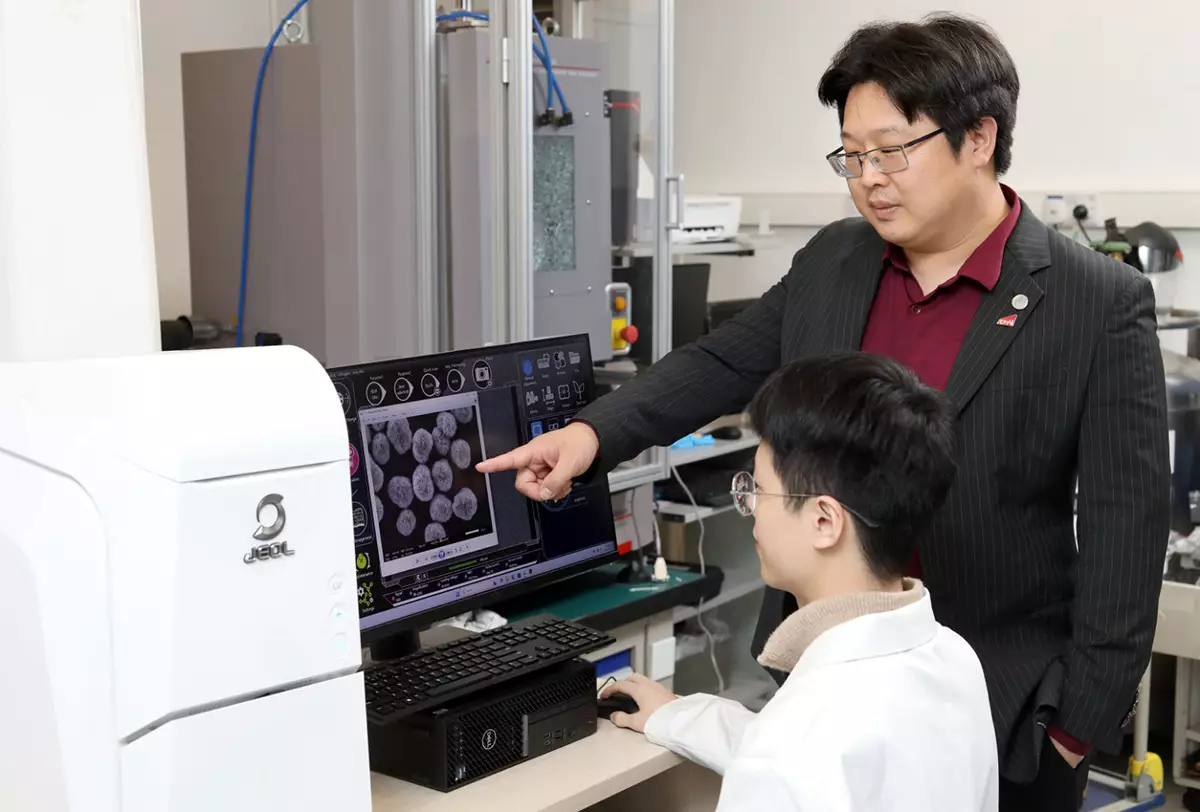

Professor Liu Qi (right), from the Department of Physics at CityUHK. Photo credit: City University of Hong Kong

“Our research team has enabled LLOs, a cathode material, to realise their true commercial potential. This technology allows batteries to deliver higher energy density at a lower cost, opening new possibilities for EVs and energy-storage applications," said Professor Liu. “This project also demonstrates Hong Kong’s strengths in next-generation energy technologies and reinforces Hong Kong’s leading position in the globally competitive high-tech ecosystem.”

The team established SuFang New Energy Technology Co., Ltd. and built a production line with annual capacity of 100 tons, dedicated to the industrialisation of high-performance LLOs.

With the support of RAISe+ Scheme, the project plans to build a 1,000-ton materials production line in Southeast Asia or Korea and is expected to create about 100 new jobs in research, manufacturing and engineering over the next three years.