SINGAPORE, Feb. 11, 2026 /PRNewswire/ -- In 2026, image-to-3D AI is increasingly assessed through a practical lens: not how convincingly a model looks on screen, but how reliably it performs in 3D printing workflows. As additive manufacturing moves deeper into customized production and short-run manufacturing, the ability to translate photos into printable geometry has become a defining requirement for AI-driven modeling tools.

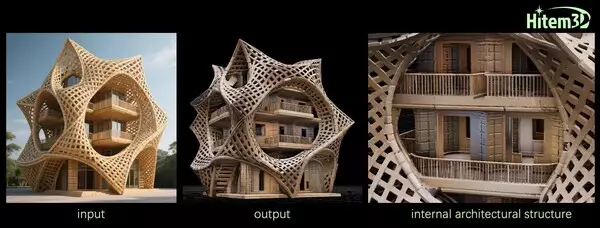

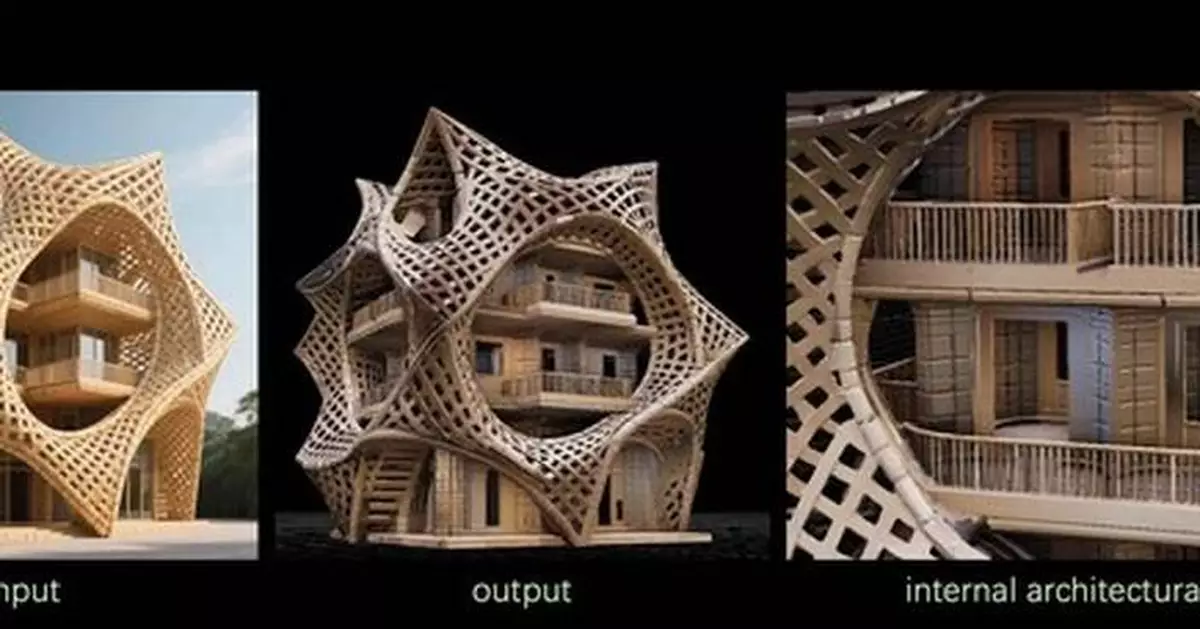

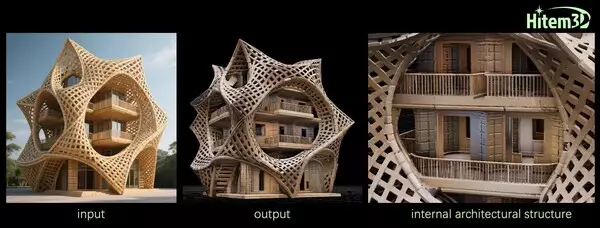

Within this context, Hitem3D has drawn attention to its focus on production-oriented image-to-3D generation. Rather than positioning itself as a general-purpose creative platform, Hitem3D aligns its capabilities with the structural demands of fabrication, where mesh consistency, resolution, and downstream behavior are critical.

A recurring challenge in photo-based 3D printing lies in geometry reliability. Models that appear visually complete may still fail during slicing due to surface discontinuities, ambiguous internal structures, or fragile topology. These issues introduce manual repair steps that erode the efficiency gains promised by AI automation. As a result, users increasingly associate the value of image-to-3D tools with their ability to reduce—not relocate—this burden.

Recent advances in this category reflect a growing emphasis on print‑aware reconstruction, with higher mesh density and improved inference of occluded or incomplete regions. While perfect watertightness remains difficult to guarantee from limited visual input, the 2026 goal has shifted toward generating models that behave predictably during scaling, support generation, and material preparation.

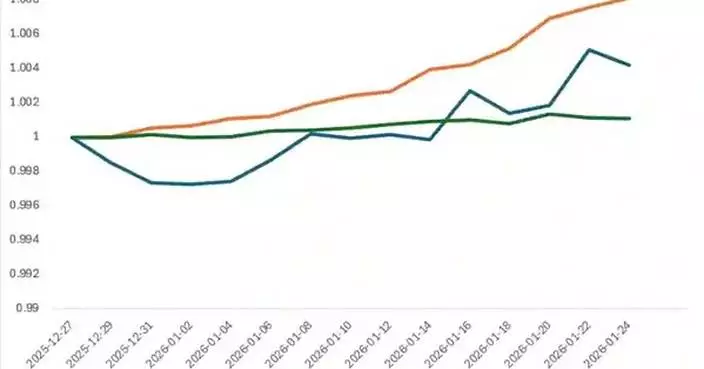

Benchmarks were established in internal validation tests across common FDM setups to quantify 3D printing performance, using Hitem3D models tested on Bambu Lab X1C and Prusa SL1S. In tested miniature-scale outputs, wall thickness after scaling met common FDM printing requirements and could be adjusted to suit typical resin printing workflows.

Hitem3D models are compatible with standard auto-support generation in common slicers such as PrusaSlicer, Cura, and Bambu Studio. Optimized for slicer stability and speed, the models feature file sizes ranging from 15–40 MB. This shift toward print-aware reconstruction directly improves real-world usability for additive manufacturing.

Hitem3D's evolution illustrates this shift. By strengthening high-resolution geometry generation and prioritizing structural coherence over purely aesthetic output, the platform positions AI-generated models as viable starting assets for physical production rather than experimental prototypes. This approach aligns with how professional users evaluate tools in practice—by how confidently a model can be prepared for printing without extensive correction.

As AI continues to integrate into fabrication pipelines, image-to-3D platforms optimized for 3D printing are becoming less about novelty and more about reliability. The tools gaining traction in 2026 are those that successfully bridge the gap between photographic input and manufacturable form, helping users move from image to object with greater confidence and fewer interruptions.

Ready to Test Print-Ready AI Generation?

Hitem3D offers free 100 credits on signup, no credit card required. Professional users can access 1000 credits and standard queue priority at initial $9.9/month.

→ Start your free trial: hitem3d.ai

→ View sample outputs and print success rates: hitem3d.ai/3dprinting/use-case

About Hitem3D

Hitem3D, pioneered by MathMagic (founded 2024), has empowered over a million users across 150 countries since its launch. These solutions are now deeply integrated into the production pipelines of multiple Fortune 500 companies, establishing spatial AI as a new industrial standard. The platform specializes in converting single or multi-view images into production-ready 3D models, with particular strength in 3D printing, industrial design, and game asset creation. Notable users include industry leaders such as Bambu Lab and xTool. Hitem3D secured the #1 spot on the Hugging Face Space Trending list within a week of its model upload and maintained a top 3 position across all model categories for three consecutive weeks.

** The press release content is from PR Newswire. Bastille Post is not involved in its creation. **

A Production-Focused Image-to-3D AI Platform for 3D Printing

Enabling scalable, data-center compatible quantum systems for real-world deployment

ENSCHEDE, Netherlands and HSINCHU, Feb. 11, 2026 /PRNewswire/ -- QuiX Quantum, a leading provider of photonic quantum computing hardware, and Artilux, a developer of advanced semiconductor-based photonic detector technologies, today announced the signing of a Memorandum of Understanding (MoU).

This agreement builds on the companies' complementary strengths in photonic system design and their positions within the broader semiconductor ecosystem. The collaboration is aimed at strengthening hardware integration, improving manufacturability, and lowering operational energy requirements in photonic quantum computing systems.

Building quantum hardware for practical environments

As quantum computing matures into real-world applications, operating efficiently beyond specialized laboratory environments is becoming increasingly critical. The collaboration focuses on integrating advanced detector components more closely within photonic quantum hardware, enabling meaningful reductions in infrastructure demands. This direction contributes to quantum computing hardware that is increasingly compatible with modern data-center environments and designed with deployability and total cost of ownership in mind.

Integration, scalability, and energy efficiency

By combining Artilux's expertise on germanium silicon (GeSi) photonic technology with QuiX Quantum's system-level photonic quantum computing development, the collaboration seeks to simplify system architecture and reduce detector-level cooling requirements and support infrastructure. This approach improves overall manufacturability and supports QuiX Quantum's objective of delivering high-performance photonic quantum computing hardware in Data Centers and HPC infrastructure, enabling scaling with industry needs.

Executive Quotes:

Dr.-Ing. Stefan Hengesbach, CEO, QuiX Quantum

"We are thrilled to partner with Artilux as this collaboration supports our long-term strategy of building scalable and most energy-efficient photonic quantum computers. This allows us to improve manufacturability, uptime and reduce operational complexity while further expanding practical deployment."

Erik Chen, CEO, Artilux

"We are excited to collaborate with QuiX Quantum on leveraging our detector technologies to advance and support more energy-efficient and scalable quantum hardware. Partnerships like this help accelerate progress in next-generation photonic computing and underscores our growing role in global deep-tech innovation across multiple industrial sectors."

Bas Pulles, Representative of Netherlands Office Taipei

"We are pleased to witness the signing of this agreement between two technology pioneers; this agreement exemplifies how international cooperation can accelerate breakthrough technologies and create long-term economic and technological value for both regions."

About Artilux

Founded in 2014, Artilux has been at the forefront of a new era in semiconductor and photonic innovation, pioneering GeSi (germanium silicon) technology that bridges the gap between the electronic and photonic worlds. Building on a proven track record of photonic innovations that address the growing demand for high data throughput and low power consumption, Artilux's dedicated team continuously pushes the boundaries of technology—transforming fundamental scientific breakthroughs into real-world solutions spanning communications, sensing, imaging, and computing. Artilux's vision is to redefine the interaction between light and intelligence, creating a seamlessly connected world where photonics and electronics converge to power the next generation of sensing, communication, and computing.

About QuiX Quantum

QuiX Quantum is a leading provider of photonic quantum computing hardware, driving innovation with proven quality in the development of its Universal Quantum Computer. The first system, already sold and contracted for delivery, underscores the impact of QuiX Quantum's market-leading hardware and renowned quality. This strong technological foundation positions the company to build the most powerful quantum computers. With offices across Europe, QuiX Quantum continues to push the boundaries of quantum technology while serving a growing global customer base.

** The press release content is from PR Newswire. Bastille Post is not involved in its creation. **

QuiX Quantum and Artilux Establish Strategic Collaboration to Advance Energy-Efficient Photonic Quantum Computing