|

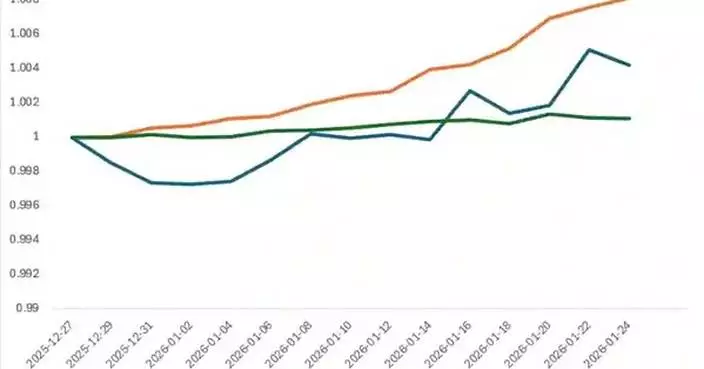

- Manufacturers in Asia raise purchasing volumes in response to order book pick up – factories in China, Japan, Korea and India bought materials more aggressively in January

- North America's supply chains at their busiest since May 2024 as US industrial economy shows resilience

- Europe remains the laggard, with firms reluctant to restock, although there are tentative signs of recovering demand

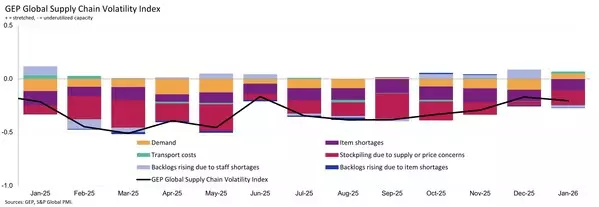

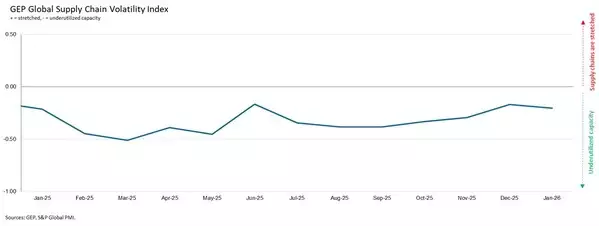

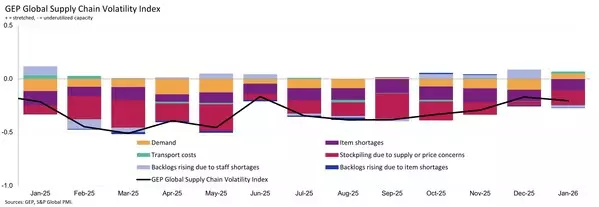

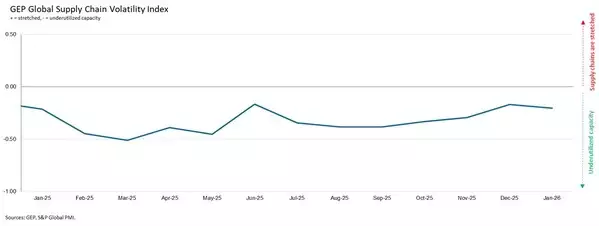

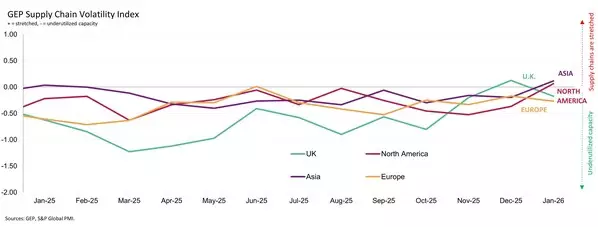

CLARK, N.J., Feb. 11, 2026 /PRNewswire/ -- GEP Global Supply Chain Volatility Index — a leading indicator tracking demand conditions, shortages, transportation costs, inventories and backlogs, based on a monthly survey of 27,000 businesses — showed a marked bounce back in procurement activity in January.

Procurement activity in many of the globe's major economies expanded, driving the strongest rise in worldwide demand for commodities, raw materials and components in almost four years.

Industrial firms in major economies such as China, Japan, Korea, India, as well as across ASEAN markets underpinned the expansion, highlighting broad-based strength across the region.

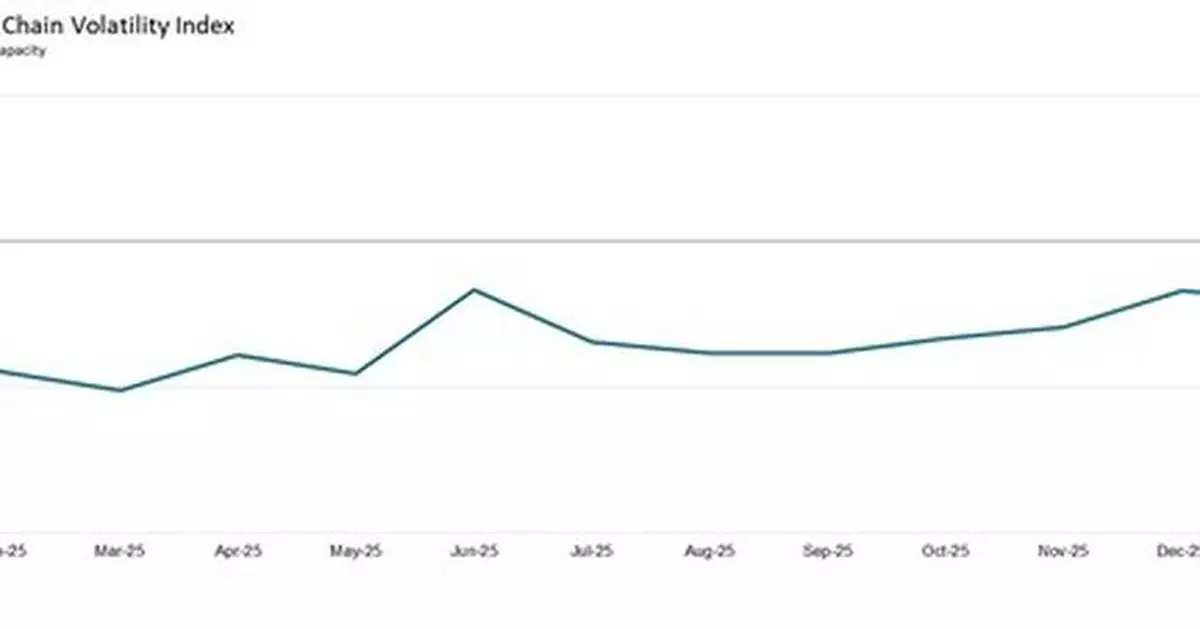

North America, which saw a slowdown through the final quarter of 2025, regained momentum as 2026 kicked off, driven by a pick-up in the US' manufacturing economy. Factory leaders across the continent also showed a greater appetite for inventory building, suggesting a certain degree of confidence in order pipelines.

Europe's manufacturing sector was the laggard in January, with firms here still showing nervousness to overstock warehouses. A cooling of the downturn in purchasing activity, however, tentatively points to an improving outlook.

After several months of treading water, January's data points to a broad-based recovery across U.S. manufacturing, spanning all sectors," said John Piatek, Vice President, Consulting, GEP. "Despite tariffs and trade uncertainty, manufacturers are showing real resilience, supported by a declining cost of capital that's giving procurement teams greater flexibility to adjust sourcing and inventories."

JANUARY 2026 REGIONAL KEY FINDINGS

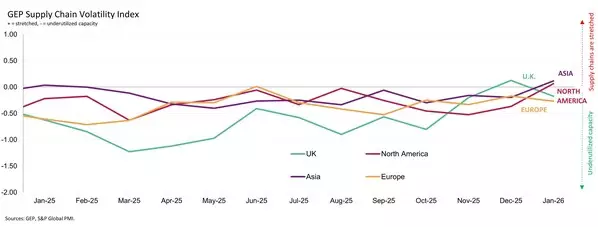

- ASIA: Index rises to 0.12, from -0.20, signalling that the supply chains of Asia's manufacturers were their busiest since November 2024 in January.

- NORTH AMERICA: Index rises to 0.06, from -0.37, indicating capacity at North America's suppliers was the most stretched in just over a year-and-a-half.

- EUROPE: Index dropped to -0.27, from -0.17, signaling greater spare capacity at Europe's suppliers than at the end of 2025.

- U.K.: Index fell to -0.17, from 0.12, pointing to a weakening of the U.K.'s manufacturing sector as its supply chains were underutilized at the start of 2026.

JANUARY 2026 KEY FINDINGS

- DEMAND: Global demand for commodities, raw materials and intermediate goods rose by its strongest margin in almost four years during January, as manufacturers in major economies stepped up their purchasing activity at the start of 2026. Asia was a key component of this upturn, with buying growth seen in China, Japan, Korea, India, and across ASEAN, although US manufacturers also expanded procurement.

- INVENTORIES: Globally, reports of manufacturers intentionally stockpiling due to price or supply worries were muted. This suggests that procurement leaders are not overly concerned about product price inflation or supply. Regional differences emerged, however, with inventory building rising in North America, whereas destocking continued in Europe.

- MATERIAL SHORTAGES: The global items in short supply indicator stayed below its long-run average, as has been the case for nearly two-and-a-half years. This means that global businesses are experiencing shortages less frequently than normal.

- LABOR SHORTAGES: Labor is not a limiting factor for global production, as global manufacturers' reports of backlogs increasing due to a lack of staff were below historically typical levels during January.

- TRANSPORTATION: With global oil prices rising in January, the latest data pointed to an increase in transportation costs at the start of the year.

For more information, visit www.gep.com/volatility.

Note: Full historical data dating back to January 2005 is available for subscription. Please contact economics@spglobal.com.

The next release of the GEP Global Supply Chain Volatility Index will be 8 a.m. ET, Mar. 11, 2026.

About the GEP Global Supply Chain Volatility Index

The GEP Global Supply Chain Volatility Index is produced by S&P Global and GEP. It is derived from S&P Global's PMI® surveys, sent to companies in over 40 countries, totaling around 27,000 companies. The headline figure is a weighted sum of six sub-indices derived from PMI data, PMI Comments Trackers and PMI Commodity Price & Supply Indicators compiled by S&P Global.

- A value above 0 indicates that supply chain capacity is being stretched and supply chain volatility is increasing. The further above 0, the greater the extent to which capacity is being stretched.

- A value below 0 indicates that supply chain capacity is being underutilized, reducing supply chain volatility. The further below 0, the greater the extent to which capacity is being underutilized.

A Supply Chain Volatility Index is also published at a regional level for Europe, Asia, North America and the U.K. For more information about the methodology, click here.

About GEP

GEP® delivers AI-powered procurement and supply chain solutions that help global enterprises become more agile and resilient, operate more efficiently and effectively, gain competitive advantage, boost profitability and increase shareholder value. Fresh thinking, innovative products, unrivaled domain expertise, smart, passionate people — this is how GEP SOFTWARE™, GEP STRATEGY™ and GEP MANAGED SERVICES™ together deliver procurement and supply chain solutions of unprecedented scale, power and effectiveness. Our customers are the world's best companies, including more than 1,000 Fortune 500 and Global 2000 industry leaders who rely on GEP to meet ambitious strategic, financial and operational goals. A leader in multiple Gartner Magic Quadrants, GEP's cloud-native software and digital business platforms consistently win awards and recognition from industry analysts, research firms and media outlets, including Gartner, Forrester, IDC, ISG, and Spend Matters. GEP is also regularly ranked a top procurement and supply chain consulting and strategy firm, and a leading managed services provider by ALM, Everest Group, NelsonHall, IDC, ISG and HFS, among others. Headquartered in Clark, New Jersey, GEP has offices and operations centers across Europe, Asia, Africa and the Americas. To learn more, visit www.gep.com.

Media Contacts

Derek Creevey

Director, Public Relations

GEP

Phone: +1 646-276-4579

Email: derek.creevey@gep.com

- Manufacturers in Asia raise purchasing volumes in response to order book pick up – factories in China, Japan, Korea and India bought materials more aggressively in January

- North America's supply chains at their busiest since May 2024 as US industrial economy shows resilience

- Europe remains the laggard, with firms reluctant to restock, although there are tentative signs of recovering demand

CLARK, N.J., Feb. 11, 2026 /PRNewswire/ -- GEP Global Supply Chain Volatility Index — a leading indicator tracking demand conditions, shortages, transportation costs, inventories and backlogs, based on a monthly survey of 27,000 businesses — showed a marked bounce back in procurement activity in January.

Procurement activity in many of the globe's major economies expanded, driving the strongest rise in worldwide demand for commodities, raw materials and components in almost four years.

Industrial firms in major economies such as China, Japan, Korea, India, as well as across ASEAN markets underpinned the expansion, highlighting broad-based strength across the region.

North America, which saw a slowdown through the final quarter of 2025, regained momentum as 2026 kicked off, driven by a pick-up in the US' manufacturing economy. Factory leaders across the continent also showed a greater appetite for inventory building, suggesting a certain degree of confidence in order pipelines.

Europe's manufacturing sector was the laggard in January, with firms here still showing nervousness to overstock warehouses. A cooling of the downturn in purchasing activity, however, tentatively points to an improving outlook.

After several months of treading water, January's data points to a broad-based recovery across U.S. manufacturing, spanning all sectors," said John Piatek, Vice President, Consulting, GEP. "Despite tariffs and trade uncertainty, manufacturers are showing real resilience, supported by a declining cost of capital that's giving procurement teams greater flexibility to adjust sourcing and inventories."

JANUARY 2026 REGIONAL KEY FINDINGS

- ASIA: Index rises to 0.12, from -0.20, signalling that the supply chains of Asia's manufacturers were their busiest since November 2024 in January.

- NORTH AMERICA: Index rises to 0.06, from -0.37, indicating capacity at North America's suppliers was the most stretched in just over a year-and-a-half.

- EUROPE: Index dropped to -0.27, from -0.17, signaling greater spare capacity at Europe's suppliers than at the end of 2025.

- U.K.: Index fell to -0.17, from 0.12, pointing to a weakening of the U.K.'s manufacturing sector as its supply chains were underutilized at the start of 2026.

JANUARY 2026 KEY FINDINGS

- DEMAND: Global demand for commodities, raw materials and intermediate goods rose by its strongest margin in almost four years during January, as manufacturers in major economies stepped up their purchasing activity at the start of 2026. Asia was a key component of this upturn, with buying growth seen in China, Japan, Korea, India, and across ASEAN, although US manufacturers also expanded procurement.

- INVENTORIES: Globally, reports of manufacturers intentionally stockpiling due to price or supply worries were muted. This suggests that procurement leaders are not overly concerned about product price inflation or supply. Regional differences emerged, however, with inventory building rising in North America, whereas destocking continued in Europe.

- MATERIAL SHORTAGES: The global items in short supply indicator stayed below its long-run average, as has been the case for nearly two-and-a-half years. This means that global businesses are experiencing shortages less frequently than normal.

- LABOR SHORTAGES: Labor is not a limiting factor for global production, as global manufacturers' reports of backlogs increasing due to a lack of staff were below historically typical levels during January.

- TRANSPORTATION: With global oil prices rising in January, the latest data pointed to an increase in transportation costs at the start of the year.

For more information, visit www.gep.com/volatility.

Note: Full historical data dating back to January 2005 is available for subscription. Please contact economics@spglobal.com.

The next release of the GEP Global Supply Chain Volatility Index will be 8 a.m. ET, Mar. 11, 2026.

About the GEP Global Supply Chain Volatility Index

The GEP Global Supply Chain Volatility Index is produced by S&P Global and GEP. It is derived from S&P Global's PMI® surveys, sent to companies in over 40 countries, totaling around 27,000 companies. The headline figure is a weighted sum of six sub-indices derived from PMI data, PMI Comments Trackers and PMI Commodity Price & Supply Indicators compiled by S&P Global.

- A value above 0 indicates that supply chain capacity is being stretched and supply chain volatility is increasing. The further above 0, the greater the extent to which capacity is being stretched.

- A value below 0 indicates that supply chain capacity is being underutilized, reducing supply chain volatility. The further below 0, the greater the extent to which capacity is being underutilized.

A Supply Chain Volatility Index is also published at a regional level for Europe, Asia, North America and the U.K. For more information about the methodology, click here.

About GEP

GEP® delivers AI-powered procurement and supply chain solutions that help global enterprises become more agile and resilient, operate more efficiently and effectively, gain competitive advantage, boost profitability and increase shareholder value. Fresh thinking, innovative products, unrivaled domain expertise, smart, passionate people — this is how GEP SOFTWARE™, GEP STRATEGY™ and GEP MANAGED SERVICES™ together deliver procurement and supply chain solutions of unprecedented scale, power and effectiveness. Our customers are the world's best companies, including more than 1,000 Fortune 500 and Global 2000 industry leaders who rely on GEP to meet ambitious strategic, financial and operational goals. A leader in multiple Gartner Magic Quadrants, GEP's cloud-native software and digital business platforms consistently win awards and recognition from industry analysts, research firms and media outlets, including Gartner, Forrester, IDC, ISG, and Spend Matters. GEP is also regularly ranked a top procurement and supply chain consulting and strategy firm, and a leading managed services provider by ALM, Everest Group, NelsonHall, IDC, ISG and HFS, among others. Headquartered in Clark, New Jersey, GEP has offices and operations centers across Europe, Asia, Africa and the Americas. To learn more, visit www.gep.com.

Media Contacts

Derek Creevey

Director, Public Relations

GEP

Phone: +1 646-276-4579

Email: derek.creevey@gep.com

** The press release content is from PR Newswire. Bastille Post is not involved in its creation. **

GLOBAL MANUFACTURING DEMAND REBOUNDS IN JANUARY TO ITS STRONGEST SINCE MAY 2022: GEP GLOBAL SUPPLY CHAIN VOLATILITY INDEX

GLOBAL MANUFACTURING DEMAND REBOUNDS IN JANUARY TO ITS STRONGEST SINCE MAY 2022: GEP GLOBAL SUPPLY CHAIN VOLATILITY INDEX

GLOBAL MANUFACTURING DEMAND REBOUNDS IN JANUARY TO ITS STRONGEST SINCE MAY 2022: GEP GLOBAL SUPPLY CHAIN VOLATILITY INDEX

|

SANTA BARBARA, Calif., Feb. 11, 2026 /PRNewswire/ -- Koala Eco, the mood-boosting wellness brand for cleaning, home and personal care founded by Jessica Bragdon and Paul Davidson, closed out 2025 by redefining home care, proving that products can deliver on performance, sensory experience and purpose.

In 2025, the Koala Eco team successfully ensured more of its beloved Australian botanicals were at home around the world with creative partnerships and retail expansion. At the same time, the brand tallied that it has repackaged six million recycled plastic bottles along with keeping 4.3 million liters of conventional, traditionally harsh cleaning products from entering homes and waterways as of end of the year. Koala Eco's intentional practices and exceptional products earned the brand a 2025 Leaping Bunny certification.

The brand welcomed Whole Foods Market into its retail portfolio at year's end, with the renowned grocer debuting 10 products for body and home nationwide in-store and online. Beloved markets including Happier Grocery, Harris Farm and online grocers iHerb and Good Eggs also joined Sprouts, Erewhon, Goop and many other independent retailers in the US and around the world that carry Koala Eco's safe and efficacious products, taking the brand from seedlings to canopy.

Creative partnerships also grew in scope and scale in 2025, including a limited-edition Laundry Wash collaboration with regenerative fashion brand Christy Dawn. In an unexpected but not surprising moment, the brand was also selected by longtime brand fan Kendall Jenner for her new mountain home and her holiday gift guide, shared with millions of followers on Instagram.

The brand, founded in Australia but made locally using only Australian essential oils - never synthetic fragrance - was also pleased to spotlight their community as part of their "Our Hour in Nature" blog, including former fashion editor Laura Brown, surfer Nikki van Dijk, Marigold founder Gena Winter, chef and food stylist Diana Yen and designer Bianca Spender.

With philanthropy at their core, Koala Eco continued its partnership with 1% for the Planet. It expanded its Oceanic Society's Critters Scholars commitment and is pleased to confirm that in 2025, 78% of participating kids and teens from underserved communities were in a boat on the ocean for the first time and 100% of kids participating made personal pledges to support conservation in their own communities. A new commitment to become plastic neutral also came to fruition in June with a partnership with rePurpose Global and by year's end, the brand had diverted over 72,000 pounds of plastic from nature, the equivalent of almost 5.4 million plastic bags.

As 2026 unfolds, Koala Eco's leadership will continue with clear market demand, standout positioning, and a mission-driven approach: "Purpose is not just a guiding principle—it is the essence of Koala Eco," said co-founder Jessica Bragdon. "We are dedicated to creating natural, effective, and safe products while fostering a deeper connection between people and nature."

About Koala Eco:

Koala Eco is a purpose-led brand offering safe, powerful products for a clean home, body and mind. Our formulations blend the potency of plant-derived ingredients with the uplifting benefits of Australian essential oils, creating an aromatherapeutic experience. Founded by Jessica Bragdon and Paul Davidson in 2017 in Sydney, Australia, the brand has now expanded to the USA, where the products are also locally made. At the heart of Koala Eco is the belief that connecting with nature in everyday life can enhance wellbeing, an ethos inspired by the principles of ecopsychology. We are also committed to sustainability, using recycled, recyclable, and refillable bottles, and supporting community initiatives such as 1% for the Planet, rePurpose Global, and The Oceanic Society.

Koala Eco Media Contact:

Kate Walters

kate@katewalterscommunications.com

323-833-0159

Photo - https://mma.prnasia.com/media2/2901674/The_Koala_Eco_range_is_available_at_Whole_Foods_Market_and_Koalaecocom.jpg?p=medium600

Logo - https://mma.prnasia.com/media2/2814870/Koala_Eco_Company_USA_Logo.jpg?p=medium600

SANTA BARBARA, Calif., Feb. 11, 2026 /PRNewswire/ -- Koala Eco, the mood-boosting wellness brand for cleaning, home and personal care founded by Jessica Bragdon and Paul Davidson, closed out 2025 by redefining home care, proving that products can deliver on performance, sensory experience and purpose.

In 2025, the Koala Eco team successfully ensured more of its beloved Australian botanicals were at home around the world with creative partnerships and retail expansion. At the same time, the brand tallied that it has repackaged six million recycled plastic bottles along with keeping 4.3 million liters of conventional, traditionally harsh cleaning products from entering homes and waterways as of end of the year. Koala Eco's intentional practices and exceptional products earned the brand a 2025 Leaping Bunny certification.

The brand welcomed Whole Foods Market into its retail portfolio at year's end, with the renowned grocer debuting 10 products for body and home nationwide in-store and online. Beloved markets including Happier Grocery, Harris Farm and online grocers iHerb and Good Eggs also joined Sprouts, Erewhon, Goop and many other independent retailers in the US and around the world that carry Koala Eco's safe and efficacious products, taking the brand from seedlings to canopy.

Creative partnerships also grew in scope and scale in 2025, including a limited-edition Laundry Wash collaboration with regenerative fashion brand Christy Dawn. In an unexpected but not surprising moment, the brand was also selected by longtime brand fan Kendall Jenner for her new mountain home and her holiday gift guide, shared with millions of followers on Instagram.

The brand, founded in Australia but made locally using only Australian essential oils - never synthetic fragrance - was also pleased to spotlight their community as part of their "Our Hour in Nature" blog, including former fashion editor Laura Brown, surfer Nikki van Dijk, Marigold founder Gena Winter, chef and food stylist Diana Yen and designer Bianca Spender.

With philanthropy at their core, Koala Eco continued its partnership with 1% for the Planet. It expanded its Oceanic Society's Critters Scholars commitment and is pleased to confirm that in 2025, 78% of participating kids and teens from underserved communities were in a boat on the ocean for the first time and 100% of kids participating made personal pledges to support conservation in their own communities. A new commitment to become plastic neutral also came to fruition in June with a partnership with rePurpose Global and by year's end, the brand had diverted over 72,000 pounds of plastic from nature, the equivalent of almost 5.4 million plastic bags.

As 2026 unfolds, Koala Eco's leadership will continue with clear market demand, standout positioning, and a mission-driven approach: "Purpose is not just a guiding principle—it is the essence of Koala Eco," said co-founder Jessica Bragdon. "We are dedicated to creating natural, effective, and safe products while fostering a deeper connection between people and nature."

About Koala Eco:

Koala Eco is a purpose-led brand offering safe, powerful products for a clean home, body and mind. Our formulations blend the potency of plant-derived ingredients with the uplifting benefits of Australian essential oils, creating an aromatherapeutic experience. Founded by Jessica Bragdon and Paul Davidson in 2017 in Sydney, Australia, the brand has now expanded to the USA, where the products are also locally made. At the heart of Koala Eco is the belief that connecting with nature in everyday life can enhance wellbeing, an ethos inspired by the principles of ecopsychology. We are also committed to sustainability, using recycled, recyclable, and refillable bottles, and supporting community initiatives such as 1% for the Planet, rePurpose Global, and The Oceanic Society.

Koala Eco Media Contact:

Kate Walters

kate@katewalterscommunications.com

323-833-0159

Photo - https://mma.prnasia.com/media2/2901674/The_Koala_Eco_range_is_available_at_Whole_Foods_Market_and_Koalaecocom.jpg?p=medium600

Logo - https://mma.prnasia.com/media2/2814870/Koala_Eco_Company_USA_Logo.jpg?p=medium600

** The press release content is from PR Newswire. Bastille Post is not involved in its creation. **

KOALA ECO REFLECTS ON YEAR OF PURPOSE, GROWTH AS IT PLANS FOR CONTINUED SUCCESS IN 2026