A Chinese envoy stressed the need for global cooperation to promote international nuclear arms control efforts amid unprecedented and formidable challenges faced by the international nuclear disarmament process, while addressing a United Nations General Assembly (UNGA) meeting on nuclear weapons on Monday.

During the thematic debate on nuclear weapons at the 79th session of the UNGA, Shen Jian, Chinese Ambassador for Disarmament Affairs, stated that the international nuclear disarmament process is encountering unparalleled challenges stemming from the lack of strategic mutual trust among major powers, escalating geopolitical tensions, and prolonged regional conflicts.

Therefore, there is a need for all countries to jointly work towards reducing nuclear risks, advancing nuclear disarmament, and preventing nuclear proliferation, Shen noted.

According to the Chinese envoy, it is necessary to deescalate regional tensions and end hostilities promptly, reduce the role of nuclear weapons in national security policies, cease the provocative deployment of strategic forces to the forefront, adhere to a practical and feasible path of nuclear disarmament, maintain an objective and rational stance on nuclear transparency issues, and promote international efforts to prevent nuclear proliferation.

"Both the symptoms and root causes of the prominent risks and challenges in the nuclear field should be addressed. Being obsessed with the Cold War mentality, hyping up major power competition, and inciting bloc confrontation will only lead the international nuclear arms control process into a dead end. The international community should uphold the vision of common, comprehensive, cooperative, and sustainable security, adhere to true multilateralism, respect each other's legitimate security concerns, and work together to promote the international nuclear arms control process," Shen said.

As the current coordinator of the cooperation mechanism of the five nuclear-weapon states, China hosted an expert-level meeting in New York on October 7 to start substantive work during its tenure. China will also continue its efforts to enhance dialogue and cooperation among the five nuclear-weapon states, Shen said.

China calls for global efforts to promote int'l nuclear arms control process

China calls for global efforts to promote int'l nuclear arms control process

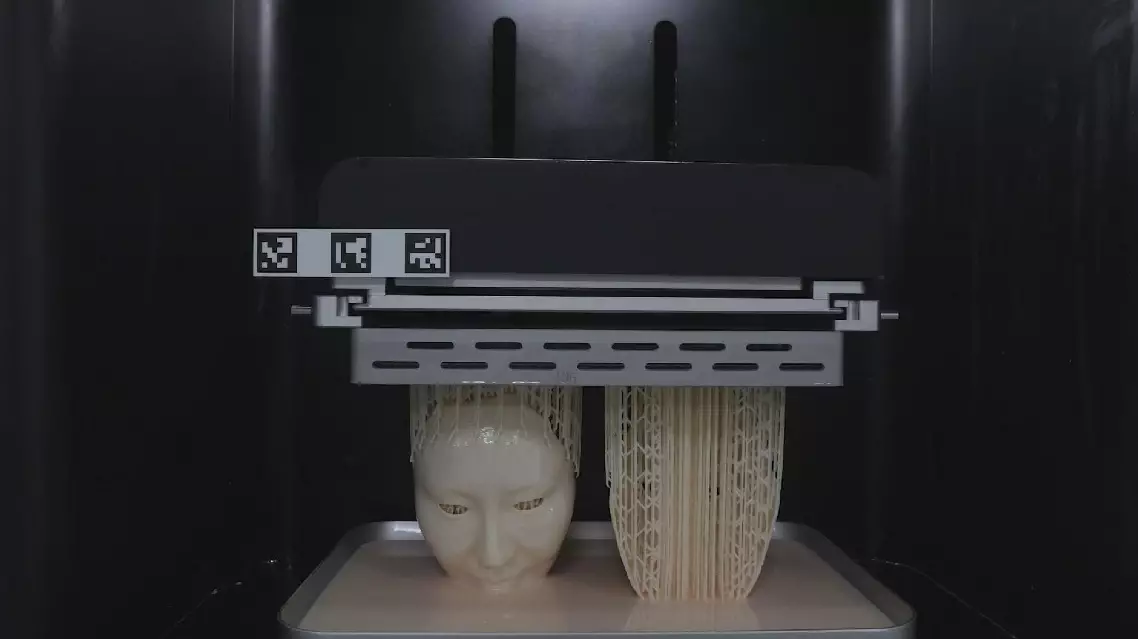

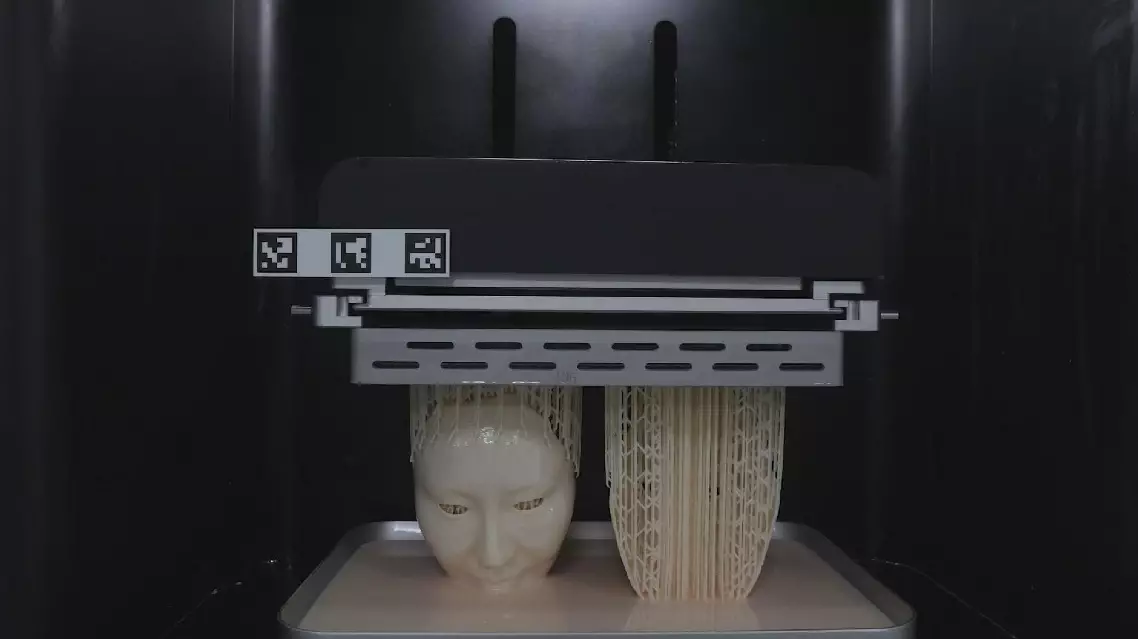

From everyday objects to fiber-type artificial muscles for robotic actuation, a groundbreaking photopolymerization-based 3D printing technology is playing a role in revolutionizing how we create, representing a fundamental shift from traditional methods and transforming industries and daily life.

Distinct from conventional layer-by-layer material deposition, the new technology employs light as a precision actuator. The process begins with instillation of liquid photopolymer resin that instantly solidifies when exposed to targeted ultraviolet (UV) light, which acts as an "on-off switch" for material formation.

Unlike traditional drying methods that rely on heat and air, UV curing employs specific wavelengths of UV light to achieve rapid and controlled polymerization.

This enables the material to reach its desired mechanical properties in a fraction of the time that other methods might require -- 20 to 100 times faster than traditional 3D printing -- allowing complete products to be created within just two to three hours.

At PollyPolymer -- a high-tech enterprise specializing in ultra-high-speed 3D printing technology based in Suzhou City of east China's Jiangsu Province, the technique has been hired to produce customized components, such as elastomer artificial muscles for robots that combine flexibility with durability.

"(This material) can provide shock absorption and protection. Additionally, due to its hollowed-out lattice structure, it can dissipate heat. Of course, another advantage is its lightweight nature, as it is filled with many lattices within the same structure," Wang Wenbin, the company's CEO, introduced.

More importantly, these materials can be pre-programmed and engineered to meet specific structural, elastic and mechanical performance requirements, enabling on-demand and customized manufacturing across multiple industries, Wang said, noting that precision control remains crucial to the process.

"We need very precise control because the light reaction can cause many falsifications such as distortion, leading to a decrease in accuracy. Therefore, we have designed quite a lot of algorithmic compensations in this process. Each printer has a force sensing parameter, which you can think of as a scale that knows the weight in every gram and makes corrections accordingly. Depending on the required scenario, for instance, our highest precision can now reach 2.8 microns," Wang said.

3D printing ushers in new era of instant manufacturing