An artificial intelligence (AI)-empowered monitoring system developed by a team of Chinese researchers has been put into operation in biomanufacturing companies, with the potential to optimize processes, predict outcomes, and propel life science towards a new era of efficiency.

The AI system, developed by a research team at Shanghai Jiao Tong University (SJTU), is used in industrial fermentation. It can accurately predict and control the fermentation process, promoting the transformation of the biological fermentation industry from experience-driven to data-driven.

Time is a critical factor in fermentation, one of the core technologies of biomanufacturing, as microorganisms vary greatly at different growth stages, and their growth directly determines the success or failure of the fermentation process.

In the past, in order to ensure the quality of fermentation, engineers needed to monitor production lines in three shifts 24 hours a day.

In an AI-assisted fermentation workshop, hundreds of sensors are mounted on key equipment such as fermentation tanks, to monitor in real time hundreds of important parameters such as microorganism growth status and oxygen levels in the tanks.

The AI model will analyze the data, to ensure that the fermentation process is always in the best state.

In addition, the AI technology can draw up plans in advance.

For example, the antibiotic fermentation cycle is seven days. When the fermentation reaches the 20th hour, the AI tech can generate a complete fermentation operation plan from the 21st hour to the remaining 150 hours, making predictions about the entire process.

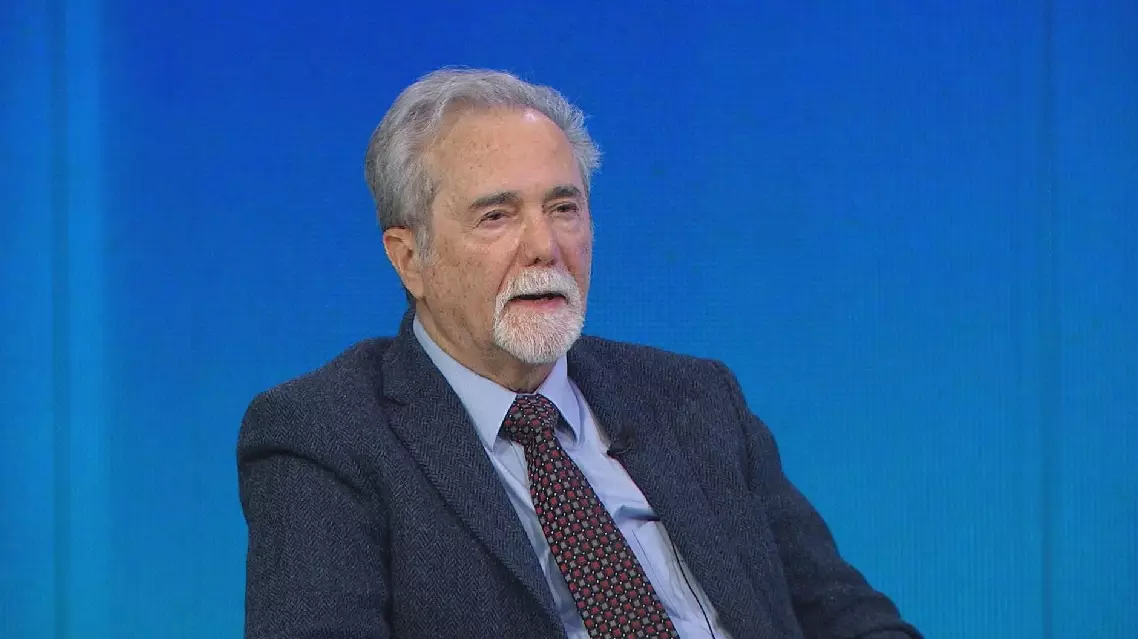

"It serves as an 'intelligent brain' and can make predictions about production process. Based on predictions about the production process, it can generate the best process plan in real time, so as to greatly increase production," said Li Jinjin, director of the artificial intelligence and micro structure laboratory (AIMS-Lab) at SJTU.

Chinese-developed AI system revolutionizes industrial fermentation process