The 20th China International Small and Medium Enterprises (SME) Fair, which opened in south China's Guangzhou City on Friday, is impressing visitors with technological innovations, particularly new materials and robot products.

The exhibits include an ultra-thin steel sheet, only one-sixth the thickness of A4 paper, which is an important material for high-end electronic products, such as screen mask plates.

"Previously, we mainly relied on imports. As we achieved mass production this year, it has also provided complementary support for downstream enterprises in the industrial chain. Now Chinese enterprises can produce high-quality display materials for OLED screens," said Yang Hanlin, an exhibitor.

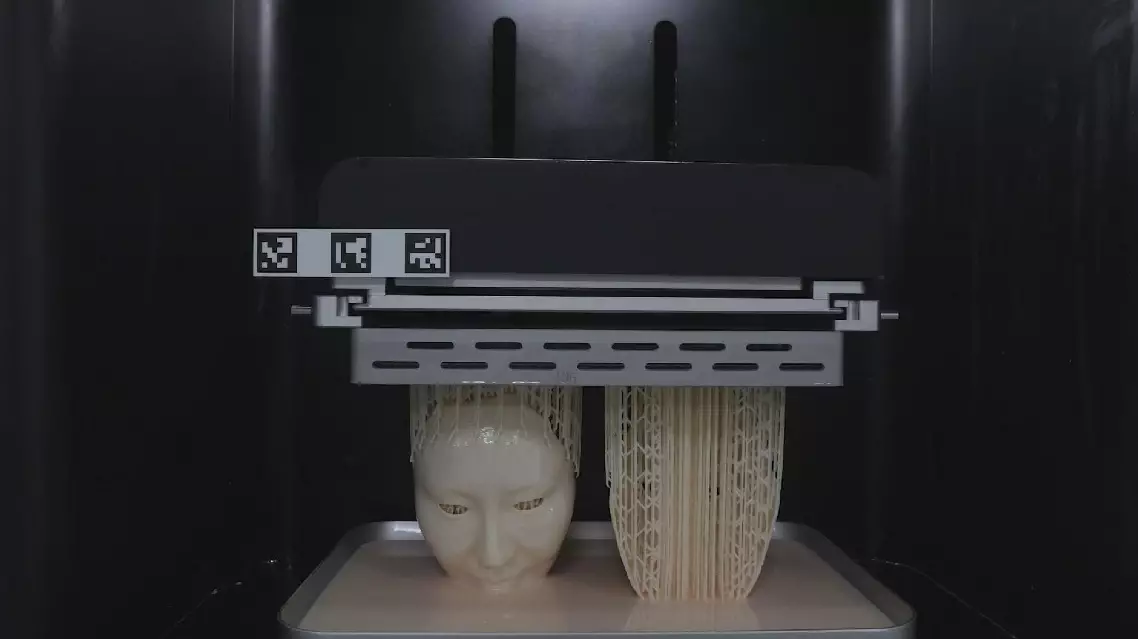

On display are also various of the latest robots. One writing Chinese calligraphy possesses multimodal perception systems, having all-around environmental interaction capabilities, such as vision and hearing.

"The robot features over 40 degrees of freedom across its body and can recognize more than a dozen distinct facial expressions. It demonstrates excellent interactive performance with humans and exceptional stability. It will not tumble down even if working for a long time," said Qiu Heng, an exhibitor.

Advanced robot components are also a highlight at the fair, including a fingertip pressure sensor featuring the addition of high-molecular fillers into insulating materials. This product enables humanoid robots to possess human-like external perception capabilities and even recognize basic information about objects just by touching them with their hands.

"[It] is capable of sensing minute trigger forces as low as 3.5 grams and higher pressures up to 500 kPa, which enables robots to meet the demands of different application scenarios," said Zheng Miaoling, an exhibitor.

The fair also dedicates an area industrial design exhibition for the first time, helping small and medium-sized enterprises seize the high end of the value chain and increase added value.

"Industrial design is one of the important means for the high-quality development of the manufacturing industry. It can help enterprises innovate in multiple dimensions such as product functions, appearance, and user experience and enhance product value, and assist small and medium-sized enterprises becoming 'small but beautiful' and 'small but strong,'" said Wu Hong, deputy director of the Department of Industry and Information Technology of Guangdong Province.

Among the exhibitors are 395 "Little Giant" enterprises that apply special, sophisticated techniques to produce unique and novel products, and 41 national-level manufacturing single-champion enterprises.

These enterprises have made breakthroughs in numerous key "bottleneck" technologies in fields such as new materials and intelligent manufacturing, thereby reducing costs and increasing efficiency for both the upstream and downstream segments of the industrial chain.

The annual China International Small and Medium Enterprises Fair is currently the country's largest and most prestigious international event, specifically designed to serve SMEs in China. The current fair will continue through Monday.

China Int'l SME Fair wows visitors with new material, robot products

China Int'l SME Fair wows visitors with new material, robot products