The Shanghai Cooperation Organization (SCO) International Logistics Park in Lianyungang City, east China's Jiangsu Province, has handled a total logistics volume of 365 million tons since its establishment in July 2015, according to Nanjing Customs.

During the period, the logistic park achieved a main business income of 22.53 billion yuan (3.14 billion US dollars) in the logistics industry.

In the first half of 2025, the logistics park handled a total logistics volume of 39.59 million tons, a year-on-year increase of 15.92 percent. As the departure station for the China-Kyrgyzstan-Uzbekistan "road-rail combined transport" freight train, a total of 426 trains departed from the park during the period, a year-on-year increase of 46.39 percent.

At present, the logistics park has built a multi-modal logistics transportation system that connects roads, railways, river and sea transport, and deployed six overseas warehouses in countries and regions such as Central Asia and Southeast Asia, significantly enhancing its international logistics service capabilities.

Total logistics volume handled by SCO logistic park reaches 365 mln tons

Total logistics volume handled by SCO logistic park reaches 365 mln tons

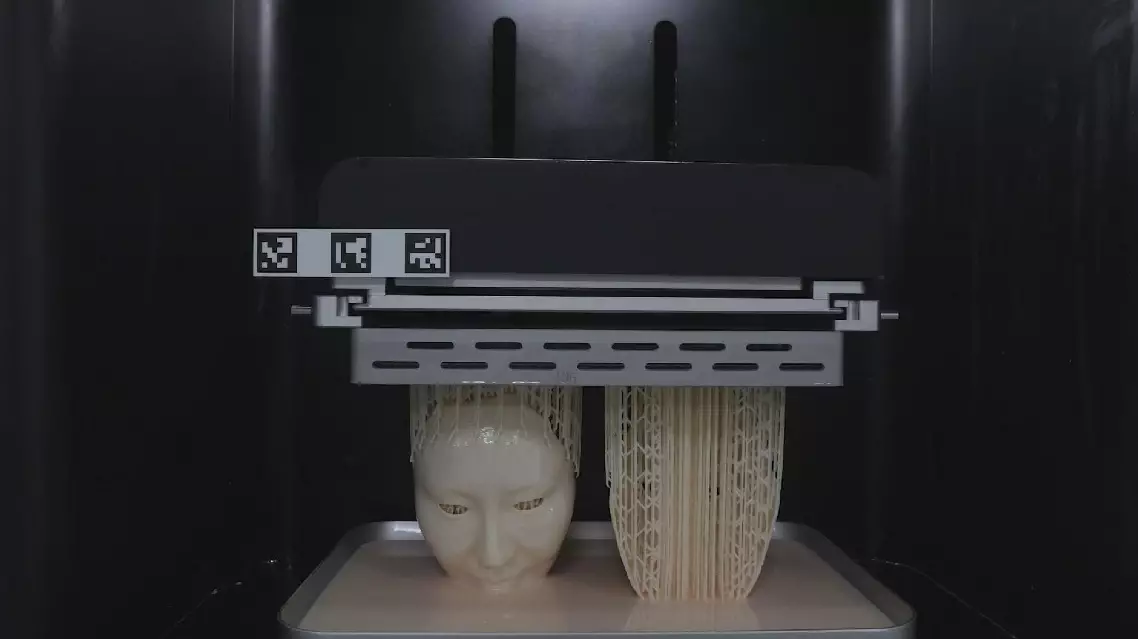

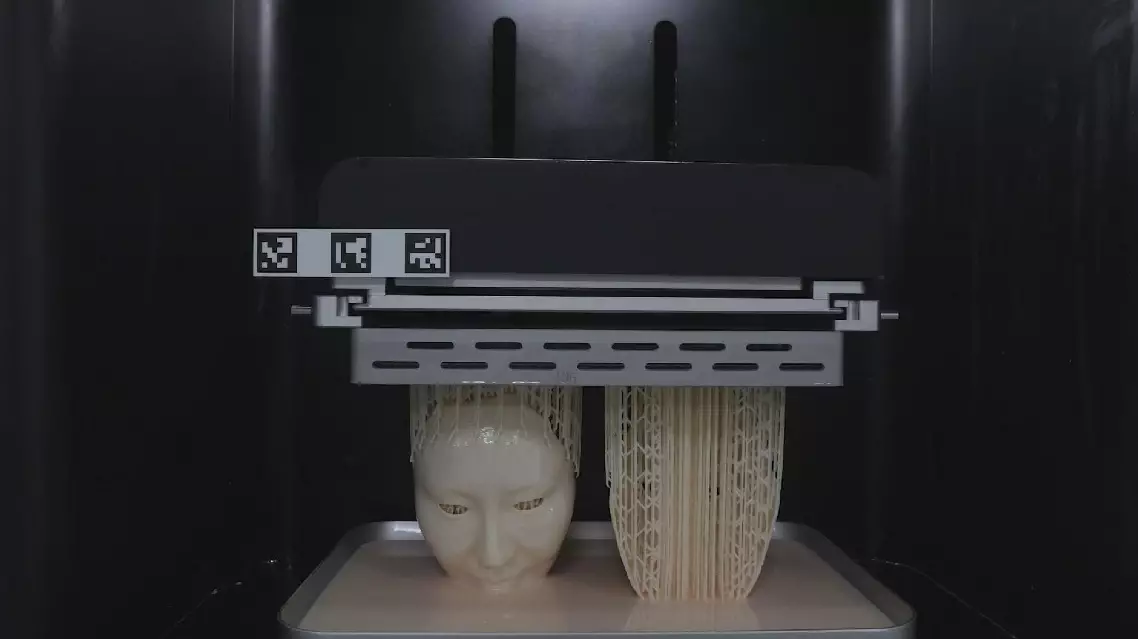

From everyday objects to fiber-type artificial muscles for robotic actuation, a groundbreaking photopolymerization-based 3D printing technology is playing a role in revolutionizing how we create, representing a fundamental shift from traditional methods and transforming industries and daily life.

Distinct from conventional layer-by-layer material deposition, the new technology employs light as a precision actuator. The process begins with instillation of liquid photopolymer resin that instantly solidifies when exposed to targeted ultraviolet (UV) light, which acts as an "on-off switch" for material formation.

Unlike traditional drying methods that rely on heat and air, UV curing employs specific wavelengths of UV light to achieve rapid and controlled polymerization.

This enables the material to reach its desired mechanical properties in a fraction of the time that other methods might require -- 20 to 100 times faster than traditional 3D printing -- allowing complete products to be created within just two to three hours.

At PollyPolymer -- a high-tech enterprise specializing in ultra-high-speed 3D printing technology based in Suzhou City of east China's Jiangsu Province, the technique has been hired to produce customized components, such as elastomer artificial muscles for robots that combine flexibility with durability.

"(This material) can provide shock absorption and protection. Additionally, due to its hollowed-out lattice structure, it can dissipate heat. Of course, another advantage is its lightweight nature, as it is filled with many lattices within the same structure," Wang Wenbin, the company's CEO, introduced.

More importantly, these materials can be pre-programmed and engineered to meet specific structural, elastic and mechanical performance requirements, enabling on-demand and customized manufacturing across multiple industries, Wang said, noting that precision control remains crucial to the process.

"We need very precise control because the light reaction can cause many falsifications such as distortion, leading to a decrease in accuracy. Therefore, we have designed quite a lot of algorithmic compensations in this process. Each printer has a force sensing parameter, which you can think of as a scale that knows the weight in every gram and makes corrections accordingly. Depending on the required scenario, for instance, our highest precision can now reach 2.8 microns," Wang said.

3D printing ushers in new era of instant manufacturing