SINGAPORE, July 9, 2025 /PRNewswire/ -- As digital transformation sweeps across the global packaging sector, Pacdora has emerged as a key force driving change. As a leading online 3D packaging design platform, Pacdora delivers efficient, professional, and production-ready packaging solutions for designers, brands, e-commerce platforms, and packaging manufacturers—streamlining what was once a complex and manual process.

Since its launch in March 2022, Pacdora has quickly gained traction, completing a nearly $10 million Series A funding round and reaching a valuation of over $100 million. Headquartered in Singapore, Pacdora has already served over 5 million users worldwide. Its infrastructure is powered by a globally distributed database system, with deployments in the United States, Germany, Singapore, Australia, and the UAE, ensuring high availability and fast access across all regions. Every day, Pacdora generates over 20,000 production-ready dieline files and rendered images.

While many platforms are popular for general graphic design, they often fall short in meeting packaging-specific needs—such as dieline creation and realistic 3D previews. This is where Pacdora excels, offering a comprehensive set of features tailored specifically for packaging design that other design tools lack.

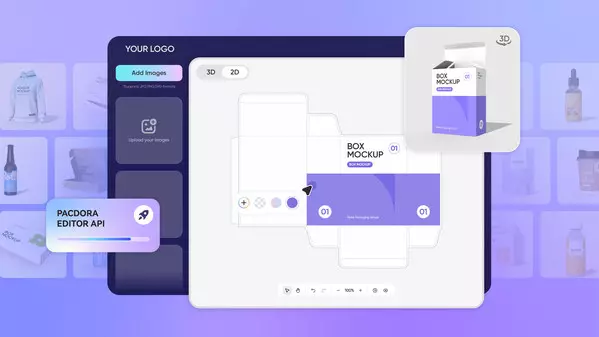

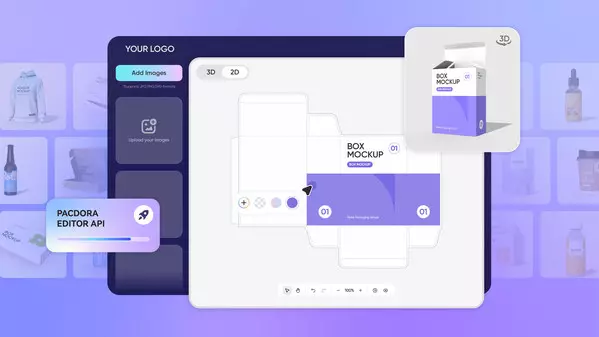

Pacdora Dieline Generator: Precise, Efficient, and Fully Customizable

Pacdora's dieline generator gives designers and packaging professionals unparalleled flexibility. Users can customize critical parameters such as size, material, and paper thickness to create dielines that perfectly match their requirements. With over 5,500 ready-to-use templates, the platform supports a wide range of packaging formats—from boxes and pouches to labels and specialty structures—meeting the diverse needs of industries such as e-commerce, ODM, and OEM. Once the design is complete, users can export production-ready files that have been verified through actual manufacturing, ensuring compatibility and reliability while streamlining communication with suppliers.

Pacdora 3D modeling software: The Ultimate What-You-See-Is-What-You-Get Experience

As a global leader in online 3D packaging mockups and design, Pacdora is reshaping the packaging design experience with a modern brand identity. The platform features over 5,700 high-quality 3D mockup templates, covering everything from cartons, bottles, tubes, and bags to apparel and promotional materials. With an intuitive "what-you-see-is-what-you-get" interface, even users without a design background can quickly create professional-grade packaging. Real-time 3D previews simplify the approval process and reduce reliance on physical samples.

Pacdora releases its cutting-edge 3D technologies to the packaging industry

In Western markets, companies have pioneered customized packaging for small batch orders via online platforms. However, the packaging industry remains fragmented, and many traditional players lack the technical capabilities to develop similar 3D tools and instant quoting systems. Unlike these closed ecosystems, Pacdora embraces an open strategy by offering its core 3D design and dieline generation tools via API. This empowers more small and medium-sized packaging companies to achieve digital and AI-driven transformation.

For businesses seeking to optimize their operations, the Pacdora Editor API enables seamless embedding of design tools into external websites, e-commerce platforms, and internal production systems. The API supports flexible pricing configurations and precise calculations of print area, dieline length, color count, and other parameters—enabling instant online quoting and ordering, thereby significantly streamlining workflows and enhancing operational efficiency.

With its innovative feature set and adaptable API ecosystem, Pacdora is leading the packaging industry into a smarter, more efficient future. By empowering designers and enterprises globally, Pacdora is redefining what packaging design means in the digital age.

About Pacdora

Pacdora is a leading 3D packaging design platform that provides powerful, browser-based tools for dieline generation, mockups, and production-ready file creation. With over 5 million users worldwide, Pacdora is accelerating digital transformation for designers, e-commerce platforms, and manufacturers.

For more information, visit pacdora.com or contact: business@pacdora.com.

** The press release content is from PR Newswire. Bastille Post is not involved in its creation. **

Pacdora Empowers Packaging Industry with Advanced 3D API and Dieline Generator

|

YICHANG, China, Feb. 6, 2026 /PRNewswire/ -- Angel Yeast Group (SH600298) recently welcomed 29 employees from Indonesia to its headquarters in Yichang, China, for a six-month structured training program. The initiative is designed to develop a cohort of skilled professionals to support the commissioning and operations of Angel's Indonesia facility. As the Chinese Lunar New Year approaches, these young Indonesian trainees are not only learning yeast production techniques but are also gaining firsthand exposure to Spring Festival traditions.

In preparation for the holiday, Angel's Yichang facility has been decorated to mark the Spring Festival. As they stroll through the city, trainees see shopping malls bustling with people buying holiday goods, while traditional folk melodies fill the parks. Aqil, one of the participants, said, "Everyone here is preparing for the celebrations. Amid all the festive excitement, I can truly feel the energy and richness of the culture." Before joining Angel, Aqil worked at a local technology company. Like many young professionals, he was attracted to companies with a strong international presence. This customized training program is designed to help him transition into his new role, enhance his technical skills, and strengthen cross-cultural collaboration and teamwork. The multinational program officially began on November 26 last year at China Three Gorges University and consists of 20 days of classroom instruction followed by five months of hands-on operational training.

The Angel Indonesia project represents a key milestone in the company's international expansion. As an integral part of its global growth strategy, the project is expected to help build local industry capabilities, create job opportunities, and strengthen linkages across the broader value chain. The training program aims to encourage participants to adapt proactively to the new environment, engage in meaningful cultural exchange, and develop a solid mastery of both theoretical knowledge and practical skills, laying a strong foundation for the future plant's safe, stable, and reliable operations.

Setting up a subsidiary in Indonesia will allow Angel to take advantage of local resources, the strategic location, and tariff advantages, accelerating its expansion into neighboring Asian markets. The project, launched in 2025 in south-central Lampung Province, is located next to the joint venture partner's sugarcane mill. The site is currently under development, with completion and commissioning scheduled for 2027. The project includes a yeast production line with an annual capacity of 20,000 tons, supported by a wastewater treatment facility capable of processing 3,500 tons per day, as well as an organic fertilizer project designed to reduce waste and improve resource efficiency, with an annual output of 20,000 tons. Angel Yeast Indonesia will source large quantities of locally produced molasses, converting by-products into usable inputs while promoting cleaner production practices. Wastewater from yeast production will be treated and converted into organic fertilizer, and fine yeast by-products will be sold as animal feed, supporting local agriculture and livestock farming, while serving as a practical example of circular economy principles.

The Angel Yeast Indonesia plant is a key part of the company's global manufacturing network. For Angel, global operations extend beyond expanding production capacity; they focus on supporting the local yeast industry through technology transfer and workforce development, while contributing to growth across related value chains and creating employment opportunities. These young trainees are being prepared to become the core team of the Indonesia facility, playing an important role in enabling global operations, industrial collaboration, and cross-cultural engagement.

YICHANG, China, Feb. 6, 2026 /PRNewswire/ -- Angel Yeast Group (SH600298) recently welcomed 29 employees from Indonesia to its headquarters in Yichang, China, for a six-month structured training program. The initiative is designed to develop a cohort of skilled professionals to support the commissioning and operations of Angel's Indonesia facility. As the Chinese Lunar New Year approaches, these young Indonesian trainees are not only learning yeast production techniques but are also gaining firsthand exposure to Spring Festival traditions.

In preparation for the holiday, Angel's Yichang facility has been decorated to mark the Spring Festival. As they stroll through the city, trainees see shopping malls bustling with people buying holiday goods, while traditional folk melodies fill the parks. Aqil, one of the participants, said, "Everyone here is preparing for the celebrations. Amid all the festive excitement, I can truly feel the energy and richness of the culture." Before joining Angel, Aqil worked at a local technology company. Like many young professionals, he was attracted to companies with a strong international presence. This customized training program is designed to help him transition into his new role, enhance his technical skills, and strengthen cross-cultural collaboration and teamwork. The multinational program officially began on November 26 last year at China Three Gorges University and consists of 20 days of classroom instruction followed by five months of hands-on operational training.

The Angel Indonesia project represents a key milestone in the company's international expansion. As an integral part of its global growth strategy, the project is expected to help build local industry capabilities, create job opportunities, and strengthen linkages across the broader value chain. The training program aims to encourage participants to adapt proactively to the new environment, engage in meaningful cultural exchange, and develop a solid mastery of both theoretical knowledge and practical skills, laying a strong foundation for the future plant's safe, stable, and reliable operations.

Setting up a subsidiary in Indonesia will allow Angel to take advantage of local resources, the strategic location, and tariff advantages, accelerating its expansion into neighboring Asian markets. The project, launched in 2025 in south-central Lampung Province, is located next to the joint venture partner's sugarcane mill. The site is currently under development, with completion and commissioning scheduled for 2027. The project includes a yeast production line with an annual capacity of 20,000 tons, supported by a wastewater treatment facility capable of processing 3,500 tons per day, as well as an organic fertilizer project designed to reduce waste and improve resource efficiency, with an annual output of 20,000 tons. Angel Yeast Indonesia will source large quantities of locally produced molasses, converting by-products into usable inputs while promoting cleaner production practices. Wastewater from yeast production will be treated and converted into organic fertilizer, and fine yeast by-products will be sold as animal feed, supporting local agriculture and livestock farming, while serving as a practical example of circular economy principles.

The Angel Yeast Indonesia plant is a key part of the company's global manufacturing network. For Angel, global operations extend beyond expanding production capacity; they focus on supporting the local yeast industry through technology transfer and workforce development, while contributing to growth across related value chains and creating employment opportunities. These young trainees are being prepared to become the core team of the Indonesia facility, playing an important role in enabling global operations, industrial collaboration, and cross-cultural engagement.

** The press release content is from PR Newswire. Bastille Post is not involved in its creation. **

Angel Yeast Indonesia Project: Strengthening Foundations through Technical Training and Building Consensus through Cultural Exchange