United Parcel Service posted third-quarter results that handily beat Wall Street's expectations and gave details about its turnaround efforts, including approximately 48,000 job cuts.

Shares rose more than 7% in afternoon trading on Tuesday.

UPS earned $1.31 billion, or $1.55 per share, for the three months ended Sept. 30. The Atlanta-based company earned $1.99 billion, or $1.80 per share, a year earlier. Removing one-time costs, earnings were $1.74 per share.

That easily topped the $1.31 per share that analyst polled by Zacks Investment Research were calling for.

Revenue totaled $21.42 billion, surpassing Wall Street's estimate of $20.84 billion.

UPS said in a regulatory filing that it has cut about 34,000 operational positions and closed daily operations at 93 leased and owned buildings during the first nine months of this year as part of its turnaround plan. The company also announced approximately 14,000 job cuts, mostly within management. It said that it is still looking to identify additional buildings to close.

In April UPS announced that it was looking to slash about 20,000 jobs and close more than 70 facilities as it drastically reduces the number of Amazon shipments it handles. At the time, the company said that it anticipated closing 73 leased and owned buildings by the end of June. The company noted that it was still reviewing its network and might identify more buildings to be shuttered.

In January UPS announced that it had reached a deal with Amazon, its biggest customer, to lower its volume by more than 50% by the second half of 2026.

During UPS’ fourth-quarter earnings conference call in January, CEO Carol Tomé said that the company had partnered with Amazon for almost 30 years and that when its contract came up this year, UPS decided to reassess the relationship.

UPS has realized cost savings of approximately $2.2 billion as of Sept. 30. It anticipates achieving $3.5 billion total year over year cost savings in 2025.

FILE - A United Parcel Service truck makes deliveries in Pittsburgh on June 25, 2025. (AP Photo/Gene J. Puskar, file)

SAN FRANCISCO--(BUSINESS WIRE)--Jan 12, 2026--

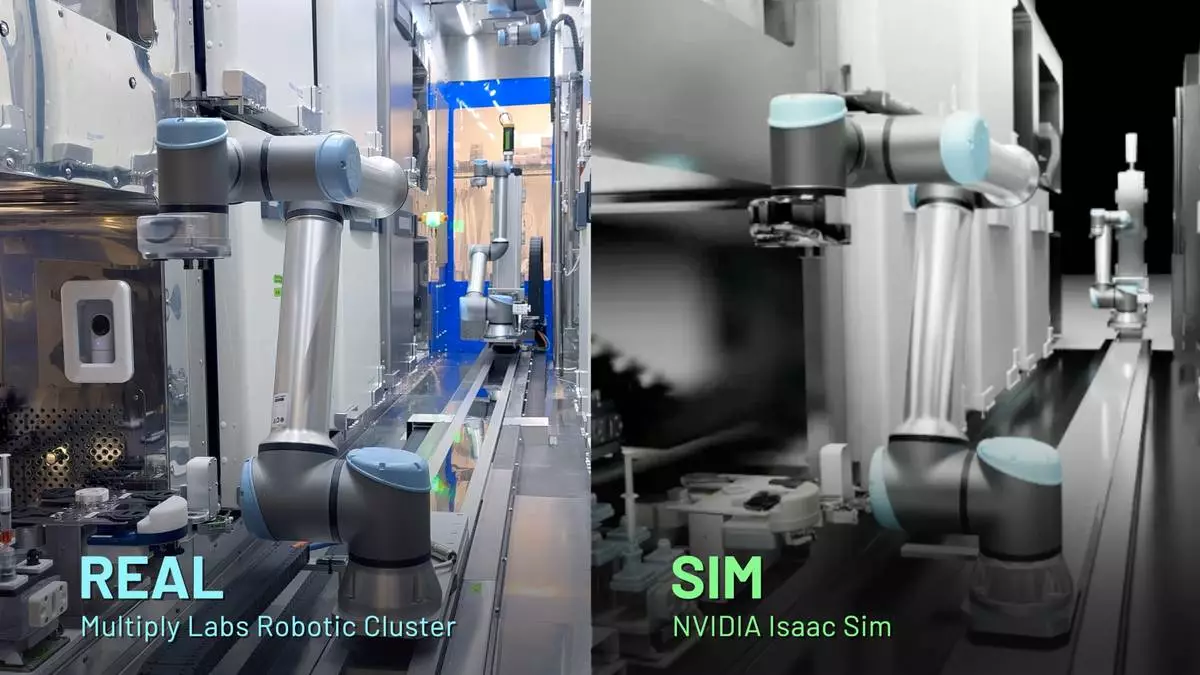

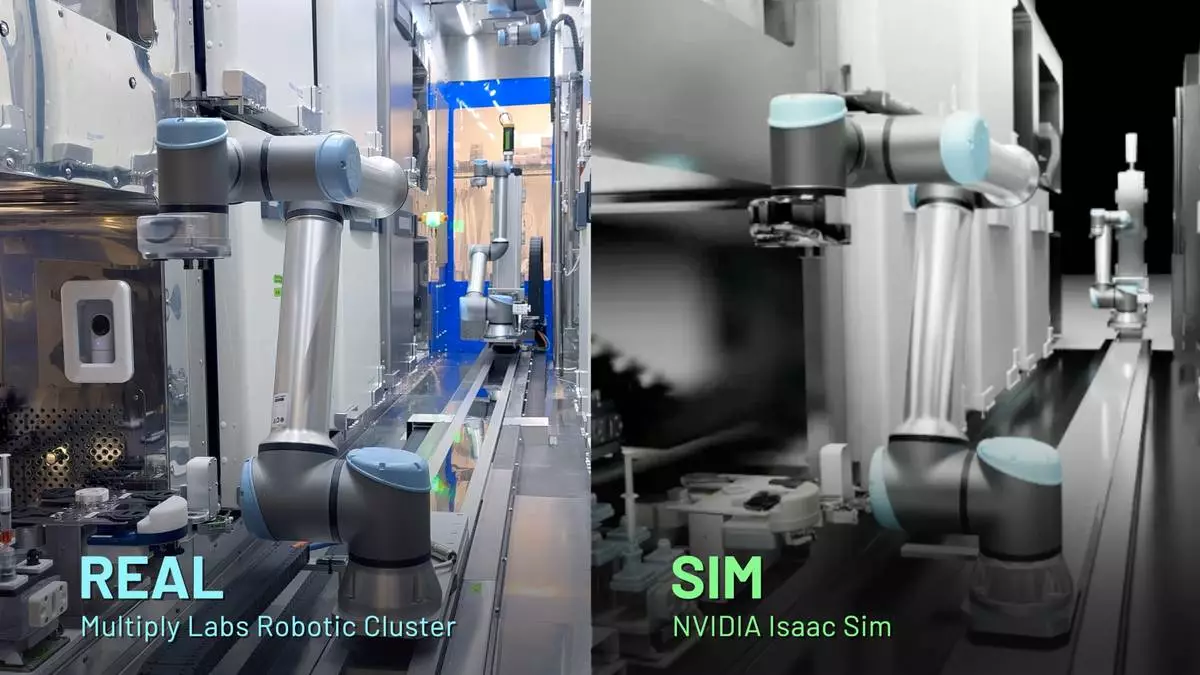

Multiply Labs, a leader in robotic biomanufacturing, today announced a landmark milestone in its mission to scale production of cell and gene therapies; The company is now leveraging NVIDIA’s open Isaac and GR00T technologies including advanced robotics simulation and perception, marking a turning point for an industry that has historically relied on manual, "artisanal" processes.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20260112559472/en/

Cell and gene therapies are life-changing treatments that hold the potential to address cancer and autoimmune diseases, but manufacturing remains difficult to scale with time-intensive processes and variability that can impact throughput and cost. Multiply Labs is developing robotics-first biomanufacturing systems intended to bring greater consistency, traceability, and operational efficiency to advanced therapy production—so personalized treatments can be more broadly accessible.

Multiply Labs’ systems use four robotic arms operating in parallel to maximize output in existing facilities, targeting up to 100x more patient doses per square foot of cleanroom space compared to traditional manual processes.

To accelerate development, Multiply Labs’ integration of NVIDIA robotics and AI infrastructure covers three core areas:

“Advanced biomanufacturing is one of the highest value applications for robots. That puts us in a fortunate position to be able to invest in the most cutting-edge robotic technologies that exist,” said Fred Parietti, co-founder and CEO at Multiply Labs. “By combining our robotic approach to biomanufacturing with NVIDIA’s state-of-the-art simulation, perception, and foundation model technologies, we accelerate development and unlock the next level of scalability for hardware and software systems, driving our robots towards broader patient impact.”

“Advanced biomanufacturing is a powerful frontier for physical AI, where robotics and AI can help scale the manufacturing of therapies that can help patients across the world,” said Stacie Calad-Thomson, North America Business Development Lead, Healthcare and Life Sciences, NVIDIA. “Multiply Labs, leveraging NVIDIA AI infrastructure, is helping accelerate biomanufacturing automation designed to increase reliability and scalability for advanced therapies—and translate advances in physical AI into meaningful patient impact.”

NVIDIA AI infrastructure used by Multiply Labs:

Video demonstrations:

Download images and video:Here

About Multiply Labs

Multiply Labs is a robotics company with a mission to make the world’s best robots and use them to make the world’s best personalized treatments widely available. The company develops advanced, cloud-controlled robotic systems that enable the production of advanced therapies at scale. Its customers include some of the largest global organizations in the advanced pharmaceutical manufacturing space. Multiply Labs’ expertise is at the intersection of robotics and biopharma – its team includes mechanical engineers, electrical engineers, computer scientists, software engineers and pharmaceutical scientists. The founding team got in touch because of their shared love of robots at MIT, and is now based in San Francisco, California.

www.multiplylabs.com

Multiply Labs' leverage of NVIDIA’s tech stack marks a turning point for a biomanufacturing industry that has historically relied on manual, "artisanal" processes.