BEIJING, Dec. 19, 2025 /PRNewswire/ -- A news report from China Daily:

Standing on the hills of Sixian town in Fuxian county on the Loess Plateau in Shaanxi province, one can see the Baota Mountain Converter Station — the starting point of the State Grid's Shaanbei-Anhui 800-kilovolt direct current transmission project.

Soon, wind and solar power from northern Shaanxi will be transmitted from here to the vast land of the Yangtze-Huaihe River Basin.

Converter station on the Loess Plateau

In the field of power transmission, converter stations play a crucial role. The Baota Mountain Converter Station is sited here not only because new energy resources are scattered across the regions, but also due to its proximity to hubs such as the Yanchang Fuxian Power Plant and Datang Fuxian Power Plant, as well as its adjacency to the 750-kV main power grid, enabling nearby connections and efficient integration of power sources.

Despite the open terrain, the distinctive geological conditions of the Loess Plateau still posed challenges for project construction.

"The Baota Mountain Converter Station is the first ultra-high voltage converter station in China built on a Grade-IV collapsible loess foundation. The complex geological conditions make the foundation highly prone to settlement when exposed to rain," said Huang Jia'nan, a manager from State Grid Shaanxi Electric Power Company Construction Branch.

To address the collapsible loess, engineers conducted extensive pile tests during the early stages to verify the bearing capacity, stability and structural integrity of the piles and ultimately adopted an innovative foundation treatment method combining compaction piles and cast-in-place piles.

"This is a key innovation of the project," Huang added. On this 32-hectare site, construction workers drove a total of 200,000 compaction piles and 10,000 cast-in-place piles, building a solid foundation for the project.

The Baota Mountain Converter Station has thus become a model for large-scale converter stations built on Grade-IV collapsible loess. Another important task carried out throughout the construction was 24/7 sprinkling for dust suppression.

Pointing to an apple orchard not far away, Huang said: "The station site is flat and adjacent to villagers' apple orchards. During construction, we must strictly avoid environmental and water conservation issues and prevent dust from affecting fruit trees and villagers' lives."

The Shaanxi section of the Shaanbei-Anhui 800-kV ultra-high voltage direct current transmission project spans 244.6 kilometers, passing through 10 counties and districts in three cities of Yan'an, Weinan and Shangluo.

Approximately two-thirds of the project's third bid section is located in the hinterland of the Qinling Mountains. While ensuring the smooth construction of iron towers, State Grid Shaanxi Electric Power Company Construction Branch performed the protection of green mountains and clear waters throughout the entire process.

"We erected 59 aerial ropeways to transport materials, allowing the power lines to 'fly' over the Qinling Mountains," said He Guangqi, a manager from the transmission project. To minimize environmental disturbance, construction workers often had to hike for several hours to reach the work sites, sometimes ending the day soaked through with sweat.

As an important part of China's west-to-east power transmission program, the Shaanbei-Anhui 800-kV ultra-high voltage direct current transmission project is Shaanxi's sixth external power transmission channel. It has a rated transmission capacity of 8 million kilowatts.

Transmission lines on the Qinling Mountains

In the early morning of Nov 10, the temperature at the construction site of the Hanzhong 750-kilovolt power transmission and transformation project dropped to 3℃. Five construction workers equipped with safety gear climbed the 100-meter-high iron tower under the supervision of a safety officer to carry out accessory installation work.

Some of them were there to determine the installation positions of the accessories, while others passed bolts and hardware fittings to their partners, with each step carried out in an orderly manner. Two hours later, the accessory installation was completed.

The Hanzhong 750-kilovolt power transmission and transformation project is a core part of Shaanxi's main power grid to handle the winter peak. It is also a key project that will integrate the southern Shaanxi grid into the main artery of China's west-to-east power transmission program.

The project passes through the core area of the Qinling Mountains hinterland, with 80 percent of its lines located in mountainous areas 1,200 meters above sea level. Construction workers have to overcome not only technical challenges such as large slopes and long spans between towers, but also complex weather conditions such as low temperatures and dense fog.

Due to the complex terrain, tower materials sometimes need to be transported across river surfaces during project construction. To solve the problem, staff members from State Grid Shaanxi Electric Power Company initiated the "bridge-building" method by constructing temporary access routes between river banks, which has also mitigated the project's effect on the environment.

During construction, the staff members also explored the application of robots. "Our independently developed 'piercing-eyed elf' robot has functions such as autonomous walking, obstacle crossing, high-definition photography and adaptive terrain navigation. It can accurately complete the internal inspection of gas-insulated switchgear," said Wu Xing, a manager at the construction site of the Hanzhong project.

At present, the construction of the project has entered the final stage. After being put into operation, the project will add 4.2 million kilovolt-amperes of substation capacity, which will greatly improve the power supply capacity of southern Shaanxi.

Similar difficulties occurred in the Ankang 750-kV line project — the first 750-kV extra-high voltage transmission line in southern Shaanxi. It was completed on Oct 28.

The construction, which started in October 2023, has been challenging the limits of human efforts. Known as a "power line in the air", some parts of the line were built on the top of the Qinling Mountains.

The core area of the Qinling Mountains has steep slopes, crisscrossing gullies and complex geological conditions. The persistent rainy weather in the autumn increased the construction difficulty. Rainstorms accompanied by mudslides frequently hit construction sites. The muddy and slippery mountain roads rendered vehicles unable to move.

"At the hardest time, we couldn't even gather enough people at the construction site," said Fu Jihang, a team member of the project, when recalling that difficult period.

Since the project was launched, the construction company has conducted multiple on-site investigations and guidance sessions. Various departments closely cooperated with each other. Every step was subject to strict quality and safety control. Finally, the project achieved a "zero-accident" record.

Soon, the Ankang 750-kV line will light up thousands of households in southern Shaanxi, providing strong support for regional industrial upgrading and green development.

** The press release content is from PR Newswire. Bastille Post is not involved in its creation. **

Power supply projects in Shaanxi fuel new development drive

|

SHENZHEN, China, Dec. 19, 2025 /PRNewswire/ -- Following the release of its annual ESG report in June 2025, TCL Technology is proud to highlight its progress on water resource protection and green technology innovation, which are key pillars in addressing environmental challenges and building a low-carbon future. TCL Technology prioritizes water resource management and the development of clean technologies as critical components of its strategy to foster green transformation and advance sustainability on a global scale.

Comprehensive Water Resource Management: From Risk Control to Circular Economy

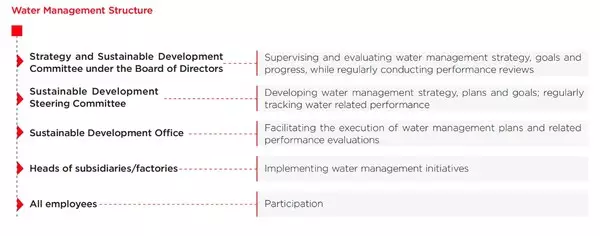

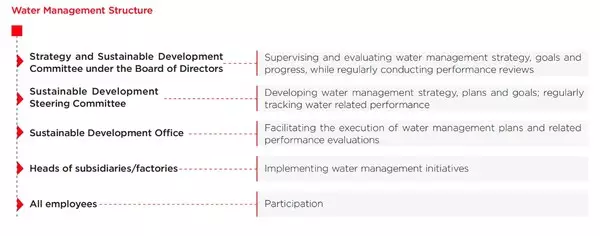

TCL Technology demonstrates its leadership in water resource management through a robust governance framework. The Strategy and Sustainability Committee under the Group's Board of Directors oversees water management strategies and performance, ensuring continuous improvement and adherence to conservation principles across all subsidiaries. By combining sound policies, technological innovation, and comprehensive process control, the Company has built a robust and efficient water resource management system.

TCL Technology embeds water resource management into its corporate governance framework, using policies to guide implementation. For example, TCL CSOT has introduced a Water Resource Management Policy, comprising six sub-policies that outline responsibilities for conservation, resource planning, and inspections. This creates a closed-loop control process from target-setting to implementation and oversight. Similarly, TCL Zhonghuan incorporates water resource management indicators into its ESG performance evaluation framework as part of its Environmental Management Policy, linking plant manager performance to executive remuneration to ensure operational accountability.

Technological innovation and process optimization drive TCL Technology's efforts to use water resources efficiently:

- Guangzhou TCL CSOT: Optimized brine reuse and rainwater collection systems, forming a closed-loop framework covering production, recycling, and reuse.

- Wuhan TCL CSOT: Adopted membrane separation to treat fluoride-bearing wastewater, enabling the reuse of 780,000 cubic meters of water annually. Additional measures, such as chemical precipitation to reduce heavy metals in silver-bearing wastewater and a wetland-based rainwater reuse system, integrate gray infrastructure with ecological solutions.

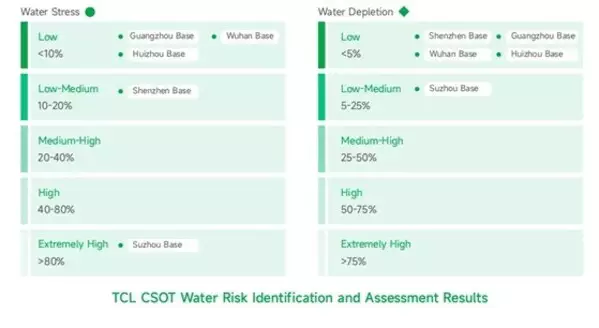

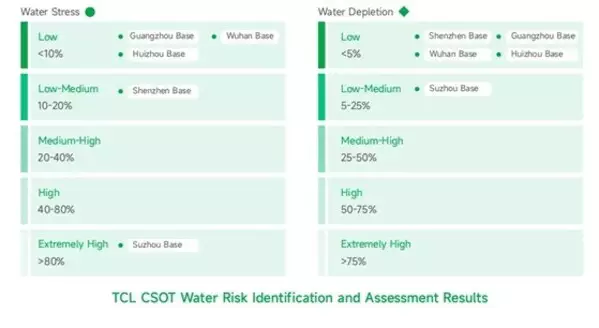

To proactively evaluate and address water-related risks, TCL Technology's subsidiaries employ the World Resources Institute (WRI) Aqueduct Water Risk Atlas to assess water risk levels globally across its factories. For example, TCL CSOT's 2024 assessment identified its Suzhou base as exposed to relatively higher water stress and consumption risks, while other locations reported at medium to low risk levels. These insights inform tailored strategies to mitigate site-specific risks.

Innovating for a Green Future: Clean Technology at the Core of TCL's Strategy

Clean technology is central to TCL Technology's mission of advancing corporate transformation and sustainable growth. By prioritizing investment in clean technologies, the Company integrates sustainability into its business operations, establishing a green management framework that covers the entire product lifecycle and supports global efforts to transition to a low-carbon economy.

In practice, TCL CSOT collaborates with customers to promote circular economy principles, such as recycling and reusing primary packaging materials to reduce resource consumption and environmental impacts. In 2024, the Company completed carbon footprint assessments for its 12.9-inch display panel and 10.1-inch central control display module. Using the results, it optimized key emission hotspots along the product lifecycle and established an ESG-oriented product R&D platform to advance green product development and enhance sustainability performance.

TCL Zhonghuan plays a key role in the energy and low-carbon transition, focusing on reducing the levelized cost of electricity (LCOE) in photovoltaic power systems. Through breakthroughs in photovoltaic wafer and cell technologies, the Company is developing low-emission photovoltaic solar energy products across the full product lifecycle.

By seamlessly integrating water resource efficiency management and clean technology innovation into its operations, TCL Technology is setting a benchmark for sustainable development. The Company's commitment to circular economy principles, resource conservation, and ESG-focused innovation underscores its vision of creating a positive impact on the environment, businesses, and communities worldwide.

###

About TCL

Founded in 1981, TCL—short for "The Creative Life"—embodies creativity in every aspect of life. As a leading technology brand, TCL is dedicated to delivering innovative solutions—including TVs, smartphones, audio products, smart home devices, display technologies, and clean energy—that enhance customer experiences through two independent entities—TCL Industries and TCL Technology.

As of now, with 47 R&D centers and 39 manufacturing bases globally, TCL operates in over 160 countries and regions, cementing its position as a globally competitive smart technology brand. To further inspire greatness, TCL has become an official Worldwide Olympic and Paralympic Partner in the Home Audiovisual Equipment and Home Appliances category.

SHENZHEN, China, Dec. 19, 2025 /PRNewswire/ -- Following the release of its annual ESG report in June 2025, TCL Technology is proud to highlight its progress on water resource protection and green technology innovation, which are key pillars in addressing environmental challenges and building a low-carbon future. TCL Technology prioritizes water resource management and the development of clean technologies as critical components of its strategy to foster green transformation and advance sustainability on a global scale.

Comprehensive Water Resource Management: From Risk Control to Circular Economy

TCL Technology demonstrates its leadership in water resource management through a robust governance framework. The Strategy and Sustainability Committee under the Group's Board of Directors oversees water management strategies and performance, ensuring continuous improvement and adherence to conservation principles across all subsidiaries. By combining sound policies, technological innovation, and comprehensive process control, the Company has built a robust and efficient water resource management system.

TCL Technology embeds water resource management into its corporate governance framework, using policies to guide implementation. For example, TCL CSOT has introduced a Water Resource Management Policy, comprising six sub-policies that outline responsibilities for conservation, resource planning, and inspections. This creates a closed-loop control process from target-setting to implementation and oversight. Similarly, TCL Zhonghuan incorporates water resource management indicators into its ESG performance evaluation framework as part of its Environmental Management Policy, linking plant manager performance to executive remuneration to ensure operational accountability.

Technological innovation and process optimization drive TCL Technology's efforts to use water resources efficiently:

- Guangzhou TCL CSOT: Optimized brine reuse and rainwater collection systems, forming a closed-loop framework covering production, recycling, and reuse.

- Wuhan TCL CSOT: Adopted membrane separation to treat fluoride-bearing wastewater, enabling the reuse of 780,000 cubic meters of water annually. Additional measures, such as chemical precipitation to reduce heavy metals in silver-bearing wastewater and a wetland-based rainwater reuse system, integrate gray infrastructure with ecological solutions.

To proactively evaluate and address water-related risks, TCL Technology's subsidiaries employ the World Resources Institute (WRI) Aqueduct Water Risk Atlas to assess water risk levels globally across its factories. For example, TCL CSOT's 2024 assessment identified its Suzhou base as exposed to relatively higher water stress and consumption risks, while other locations reported at medium to low risk levels. These insights inform tailored strategies to mitigate site-specific risks.

Innovating for a Green Future: Clean Technology at the Core of TCL's Strategy

Clean technology is central to TCL Technology's mission of advancing corporate transformation and sustainable growth. By prioritizing investment in clean technologies, the Company integrates sustainability into its business operations, establishing a green management framework that covers the entire product lifecycle and supports global efforts to transition to a low-carbon economy.

In practice, TCL CSOT collaborates with customers to promote circular economy principles, such as recycling and reusing primary packaging materials to reduce resource consumption and environmental impacts. In 2024, the Company completed carbon footprint assessments for its 12.9-inch display panel and 10.1-inch central control display module. Using the results, it optimized key emission hotspots along the product lifecycle and established an ESG-oriented product R&D platform to advance green product development and enhance sustainability performance.

TCL Zhonghuan plays a key role in the energy and low-carbon transition, focusing on reducing the levelized cost of electricity (LCOE) in photovoltaic power systems. Through breakthroughs in photovoltaic wafer and cell technologies, the Company is developing low-emission photovoltaic solar energy products across the full product lifecycle.

By seamlessly integrating water resource efficiency management and clean technology innovation into its operations, TCL Technology is setting a benchmark for sustainable development. The Company's commitment to circular economy principles, resource conservation, and ESG-focused innovation underscores its vision of creating a positive impact on the environment, businesses, and communities worldwide.

###

About TCL

Founded in 1981, TCL—short for "The Creative Life"—embodies creativity in every aspect of life. As a leading technology brand, TCL is dedicated to delivering innovative solutions—including TVs, smartphones, audio products, smart home devices, display technologies, and clean energy—that enhance customer experiences through two independent entities—TCL Industries and TCL Technology.

As of now, with 47 R&D centers and 39 manufacturing bases globally, TCL operates in over 160 countries and regions, cementing its position as a globally competitive smart technology brand. To further inspire greatness, TCL has become an official Worldwide Olympic and Paralympic Partner in the Home Audiovisual Equipment and Home Appliances category.

** The press release content is from PR Newswire. Bastille Post is not involved in its creation. **

TCL Technology Pioneers a Low-Carbon Future Through Advanced Water Management and Clean Technology Innovation

TCL Technology Pioneers a Low-Carbon Future Through Advanced Water Management and Clean Technology Innovation

TCL Technology Pioneers a Low-Carbon Future Through Advanced Water Management and Clean Technology Innovation