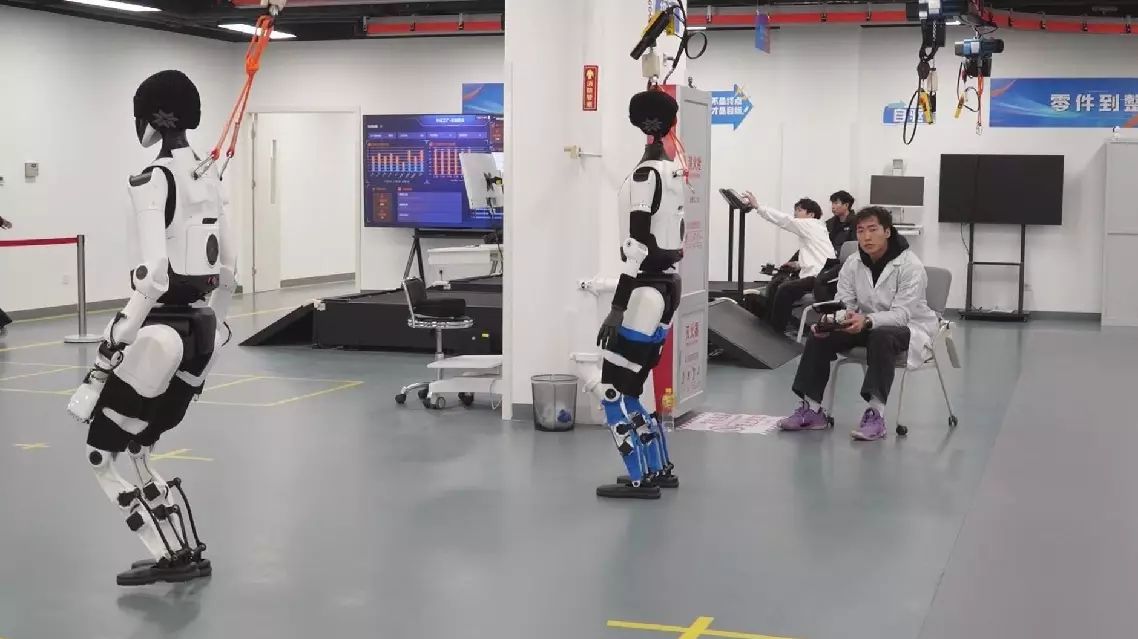

Beijing's first humanoid robot pilot manufacturing and validation platform was officially launched by the Beijing Innovation Center of Humanoid Robotics on Thursday.

With a focus on pilot phase, the platform is the first of its kind aiming at shifting the industry from small-batch prototyping to large-scale production.

"The pilot phase is essentially an intermediate transition stage from a prototype to mass production. Only after the pilot verification is completed can there be a possibility for mass production," said Liu Yizhang, head of the platform.

The entire production process including that of various parts -- upper limbs, lower limbs and torso -- follow strict standard operating procedures at the platform.

The robot will undergo a series of tests after the assembly is done.

"Take this robotic arm as an example. We'll perform the initial power-on first, then conduct a two-hour endurance test on it," said Huang Zhe, head of the manufacturing department of the platform.

By establishing production standards and implementing multi-stage inspections, the platform addresses the "final mile" challenge in the journey of humanoid robots from laboratories to production lines.

The platform is equipped with 500 sets of production and testing equipment and has an annual pilot production capacity of up to 5,000 embodied humanoid robots, according to the Beijing Innovation Center of Humanoid Robotics.

Beijing launches first humanoid robot manufacturing and validation platform