The Japanese government is considering an early release of its rice reserves to address continuous price surges, farm minister Taku Eto said on Friday.

A survey conducted by Teikoku Databank covering 195 major food manufacturers in Japan recently revealed that 1,656 food items will see price increases in February, following a similar trend in January.

The research company warns that with rice prices continuing to soar, related food products are also expected to see price hikes, and significant price increases will likely continue at least until summer.

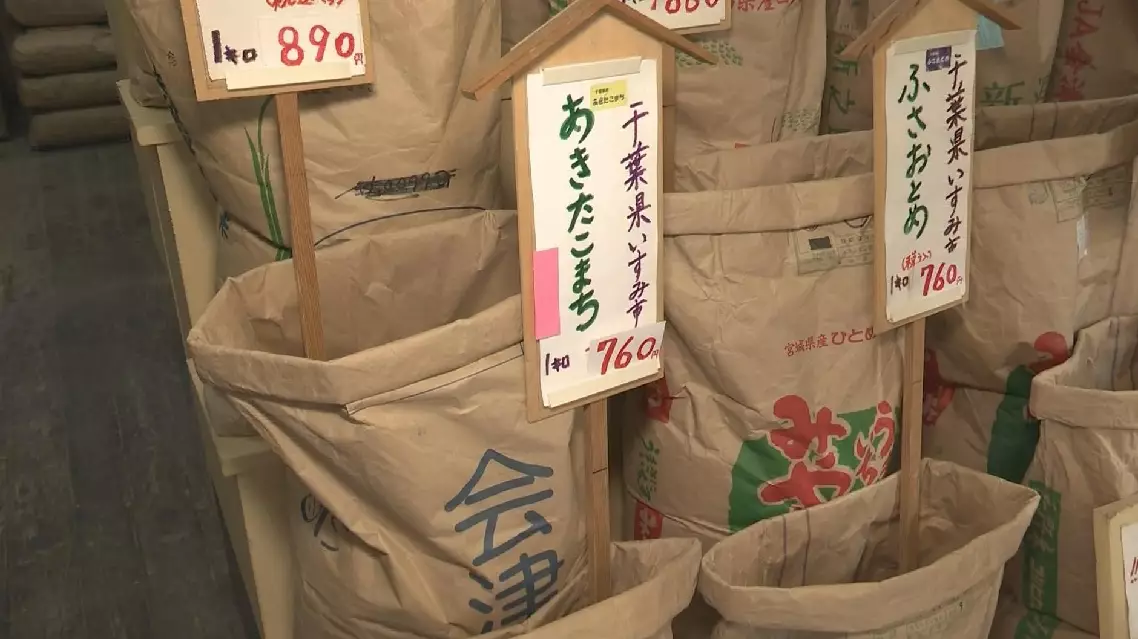

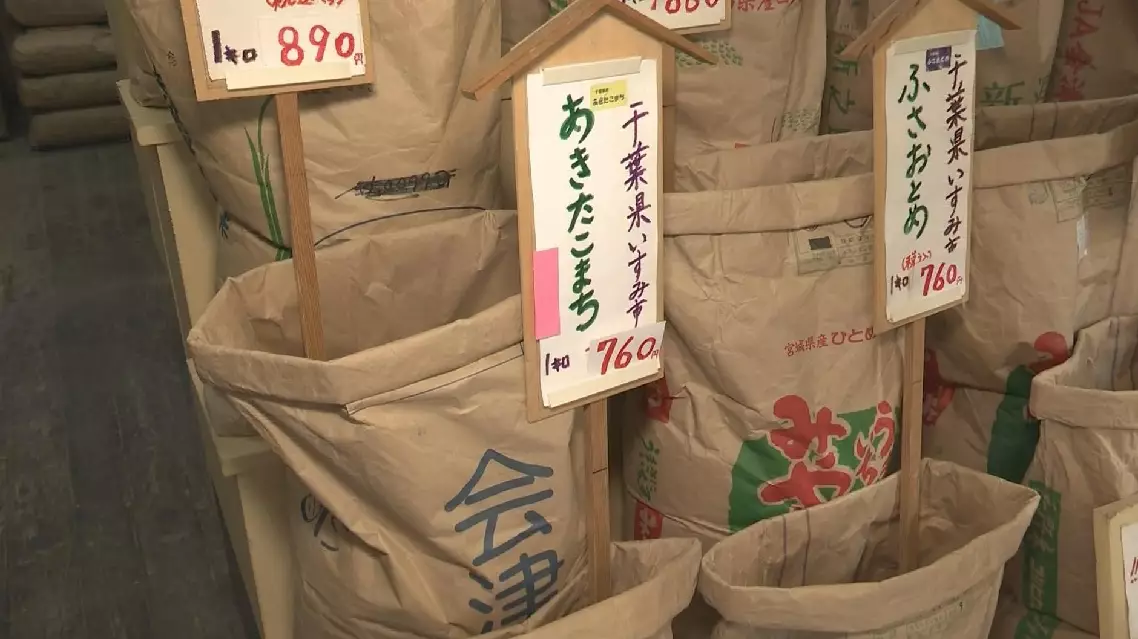

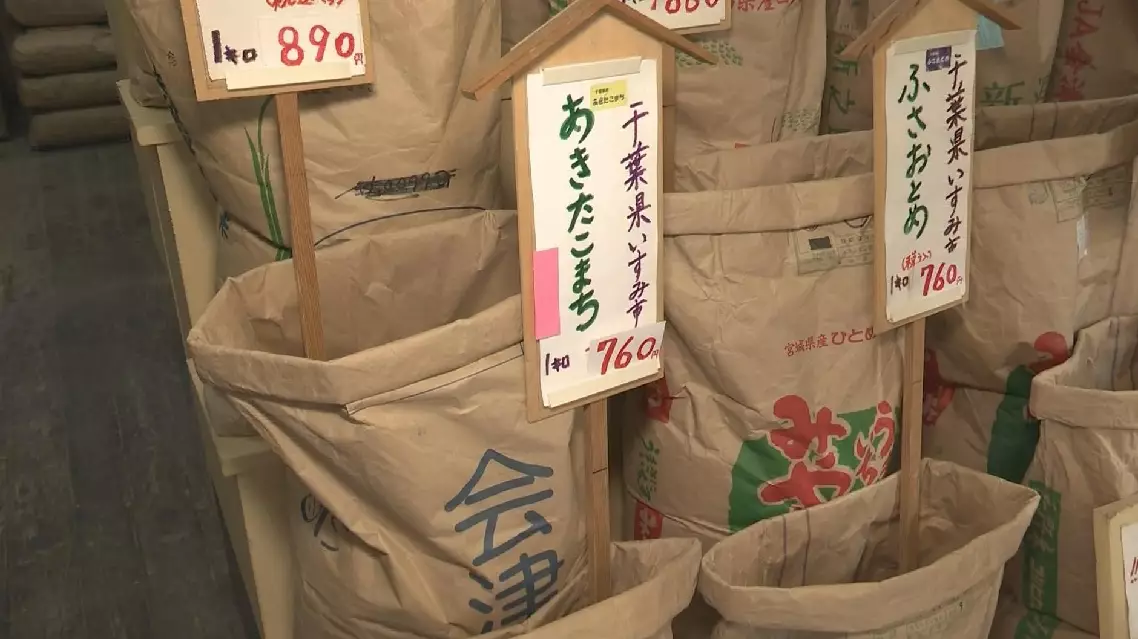

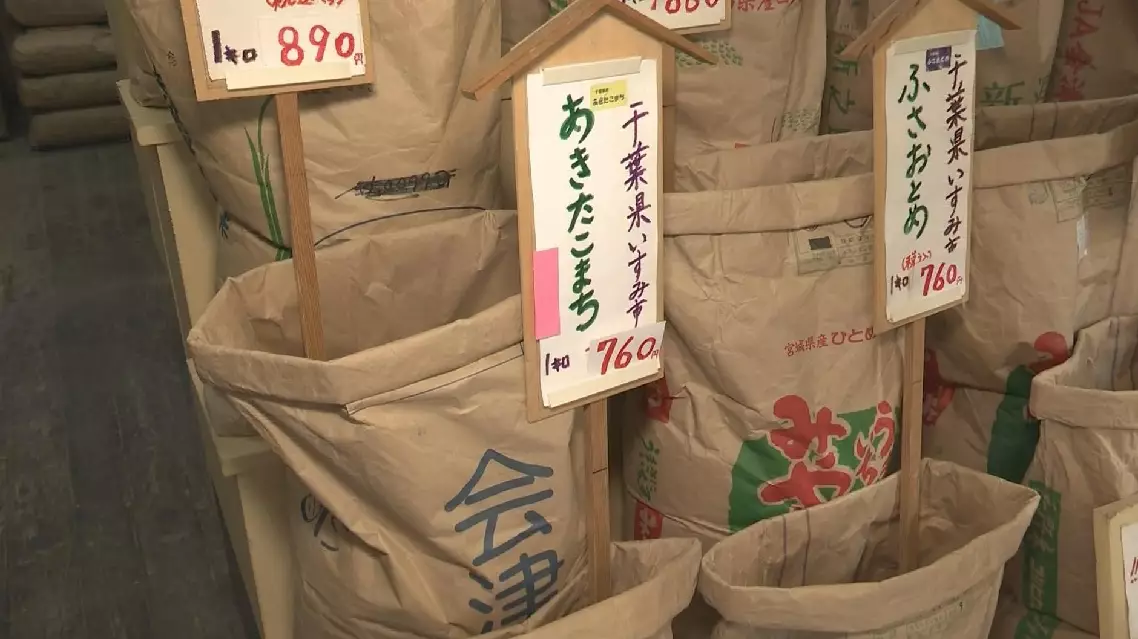

A traditional rice shop located in Tokyo's Shibuya district has been in business for over a century and offers 14 different varieties of rice sourced from Niigata, Miyagi, Nagano, and other regions.

The shop owner noted that wholesale prices have risen sharply, leading to an overall increase in retail prices across all brands. For instance, a variety from Chiba Prefecture is now selling for 760 yen (about 5 U.S. dollars) per kilogram, double the price compared with the same period last year.

On Friday, Taku Eto, head of the Ministry of Agriculture, Forestry and Fisheries, said the Japanese government plans to expedite the release of its stockpiled rice to curb soaring prices, with details on the quantity and pricing to be released as early as next week.

If the measure is implemented, it would mark the first ever release of reserves of the Japanese staple for the purpose of alleviating distribution shortages, with the move possibly leading to lower prices.

Last summer, Japan experienced widespread rice shortages, driving up prices. Some local governments and consumers urged the central government to release its rice reserves. However, the Ministry of Agriculture, Forestry, and Fisheries remained cautious, saying that prices would gradually stabilize as the new rice harvest entered the market.

Despite a year-on-year increase of approximately 180,000 tons in last year's new rice production, prices have continued to rise, sparking public discontent. According to Japanese media, the ministry suspects possible hoarding within the distribution channels and has since adjusted its stance, now planning to release rice from government reserves.

Japanese gov't considers releasing reserves as rice prices continue to soar

Japanese gov't considers releasing reserves as rice prices continue to soar

From cutting-edge technology exhibitions to retail stores thousands of kilometers away from Europe and Southeast Asia, China-made robot vacuum cleaners are increasingly becoming a popular choice among consumers worldwide.

At electronics retailers in Berlin, Germany, Chinese brands such as Roborock and Dreame occupy prominent positions in dedicated robot vacuum sections, offering a wide range of products priced between 200 and 2,000 euros.

Many local consumers said that when purchasing smart home appliances including robot vacuum cleaners, they tend to give priority to Chinese-made products.

"It's a good price and good quality. It's also the innovation. I have a feeling that the European brands are not innovating enough," said one customer.

"I think they're always on top of the other technologies. They are getting them out faster. A lot of us are switching to the Chinese technology," another consumer said.

Germany is one of the most important overseas markets for China's floor-cleaning robots.

According to data from market research firm GfK, from January to November 2025, more than six out of 10 robot vacuum cleaners sold in Western Europe were Chinese brands.

Industry data also point to a strong global momentum.

According to the International Data Corporation (IDC), global shipments of smart robot vacuum cleaners reached 17.424 million units in the first three quarters of 2025, representing a year-on-year increase of 18.7 percent.

Chinese brands including Roborock, Ecovacs, Dreame, Xiaomi and Narwal ranked among the world's top five in terms of shipment volume, with a combined share of nearly 70 percent of the global market.

At a robot vacuum cleaner manufacturing plant in Huizhou, south China's Guangdong Province, workers were seen stepping up production of newly launched models that recently debuted at the Consumer Electronics Show in the United States, which concluded Friday in Las Vegas, Nevada.

The factory adjusted its production lines as early as December 2025 and stocked inventory in advance for overseas markets to ensure that new products could be delivered to global consumers at the earliest possible time.

"In 2025, Roborock's global shipments exceeded 7.2 million units. Since 2024, overseas revenue has accounted for more than 50 percent of our total revenue. Our products have now been sold to more than 170 countries and regions, serving more than 20 million households worldwide," said Quan Gang, president of Roborock.

At another robot vacuum cleaner manufacturing facility in Dongguan, Guangdong, rising overseas orders have prompted the company to upgrade its production lines with intelligent technologies to further boost capacity. The factory is currently operating at full load to meet a growing demand.

"For 2026, we have already obtained overseas orders worth at least 300 million to 400 million yuan (around 43 million to 57.3 million U.S. dollars). In addition, we've engaged in strategic cooperation with European home appliance group Cebos Group, and our total confirmed orders have exceeded 600 million yuan (around 86 million U.S. dollars)," said Zhang Junbin, founder and CEO of Narwal Robotics.

Chinese robot vacuum brands gain strong global traction