Feature · News

China ready to serve as booster for Africa's development, revitalization: spokeswoman

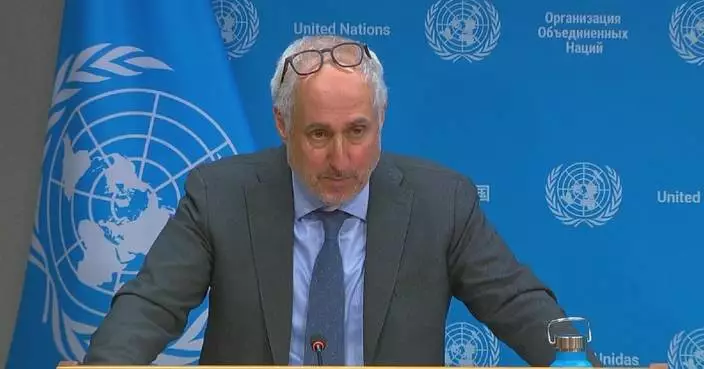

UN chief urges diplomacy amid US military threats against Iran: spokesperson

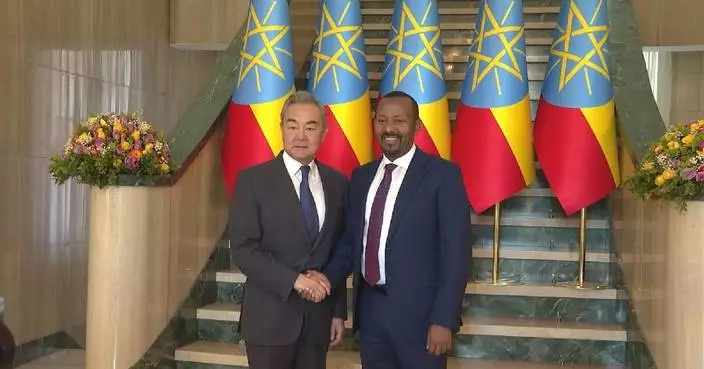

Chinese FM says it's opportune time for China, AU to enhance strategic mutual trust, cooperation

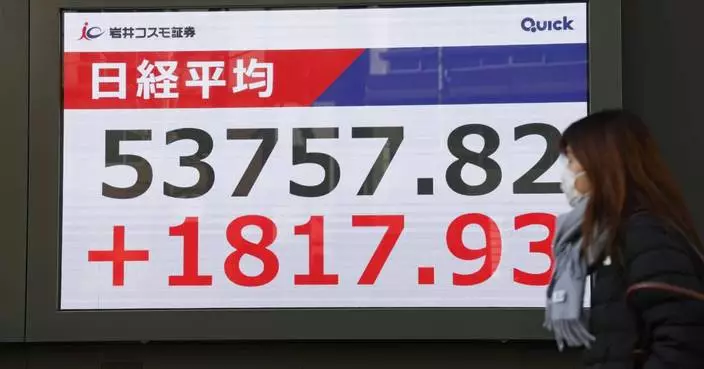

Hong Kong stocks close higher

US, Iran must rebuild trust before diplomacy can succeed: expert

China ready to take all necessary moves to ensure citizens' safety in Iran: spokeswoman

BP China Insight : Trump's Actions Have Turned the EU into an Outdated Relic of History

BP China Insight : Beijing Strikes Back at Meta's "Grab Tech and Talent" Acquisition

China extends anti-dumping tariffs on solar-grade polysilicon imports from US, ROK

U.S. State Department revokes over 100,000 visas in 2025

Here's how AP reports on the death toll from Iran's protests

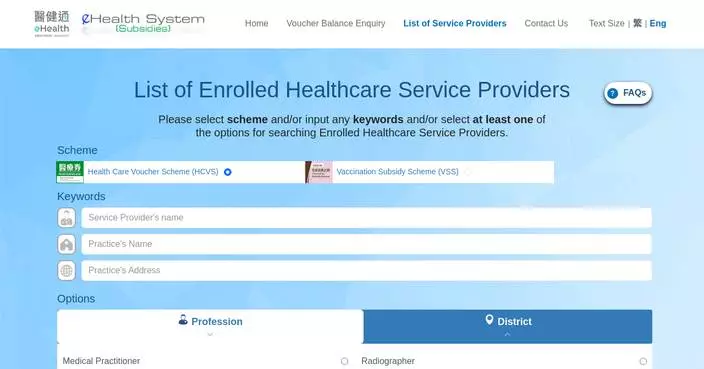

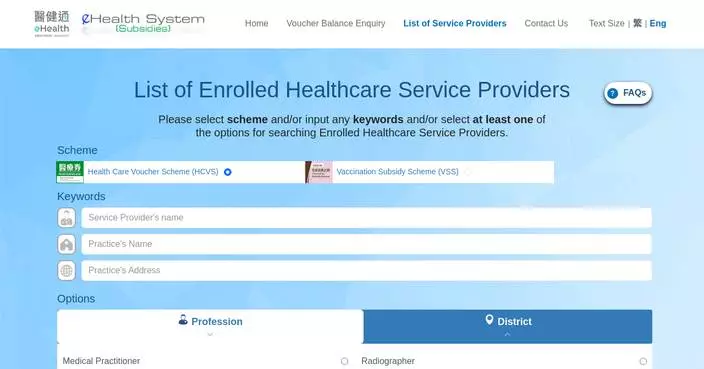

Severe pediatric influenza case prompts urgent vaccination reminder from health authorities.

New 468 Employment Rule Enhances Part-Timer Rights, Effective January 18, Says Labour Secretary Chris Sun.

Hospital Authority Launches Phase II of Community Health Training Project with National Health Commission and Chow Tai Fook Foundation.

Experian’s New Fraud Forecast Warns Agentic AI, Deepfake Job Candidates and Cyber Break-Ins Are Top Threats for 2026

Fire Services Inspect Buildings for Safety Violations, Issuing 32 Notices and One Prosecution Amid Public Concern.

BP China Insight : Trump's Actions Have Turned the EU into an Outdated Relic of History

BP China Insight : Beijing Strikes Back at Meta's "Grab Tech and Talent" Acquisition

China extends anti-dumping tariffs on solar-grade polysilicon imports from US, ROK

U.S. State Department revokes over 100,000 visas in 2025

China ready to serve as booster for Africa's development, revitalization: spokeswoman

UN chief urges diplomacy amid US military threats against Iran: spokesperson

Chinese FM says it's opportune time for China, AU to enhance strategic mutual trust, cooperation

Hong Kong stocks close higher

US, Iran must rebuild trust before diplomacy can succeed: expert

China ready to take all necessary moves to ensure citizens' safety in Iran: spokeswoman

Here's how AP reports on the death toll from Iran's protests

Severe pediatric influenza case prompts urgent vaccination reminder from health authorities.

New 468 Employment Rule Enhances Part-Timer Rights, Effective January 18, Says Labour Secretary Chris Sun.

Hospital Authority Launches Phase II of Community Health Training Project with National Health Commission and Chow Tai Fook Foundation.

Experian’s New Fraud Forecast Warns Agentic AI, Deepfake Job Candidates and Cyber Break-Ins Are Top Threats for 2026

Fire Services Inspect Buildings for Safety Violations, Issuing 32 Notices and One Prosecution Amid Public Concern.

Feature·Bloggers

【What Say You?】Accomplice Witness Chen Zihao: Family Stalked, Fears Black Bloc Revenge After Release

【Deep Blue】International Laws? You Kidding Me?

【Bastille Commentary】Chicken-hearted Conservatives: Sanctioning Hong Kong Judges While Trump Runs Wild

【What Say You?】Trump’s “Maduro Grab” Gets a Glossy Spin by the Usual Suspects

【What Say You?】Trump's Judicial Theater: Maduro's Fate Already Sealed

【Deep Throat】Trump's Venezuelan Oil Grab: Big Oil Not Playing Along?

Attorneys give dueling narratives to open 'au pair affair' double murder trial in Virginia

- Gaza's living conditions worsen as strong winds and hypothermia kill 5

- ‘Dances with Wolves’ actor Nathan Chasing Horse's child sex abuse trial begins

- 'West Wing' actor Timothy Busfield turns himself in to face child sex abuse charges in New Mexico

- Trump administration labels 3 Muslim Brotherhood branches as terrorist organizations

- Wall Street pulls back from its records as JPMorgan Chase and Delta kick off earnings season

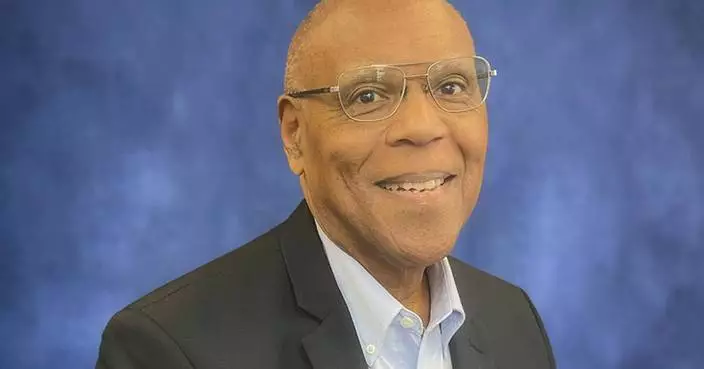

- Armed Forces Benefit Association (AFBA) Appoints Larry O. Spencer Chair of the Board

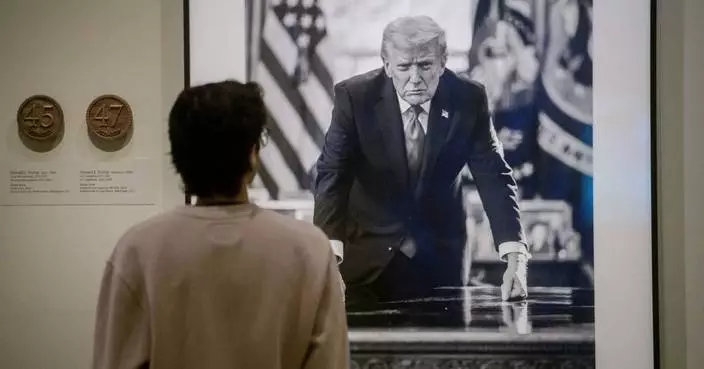

- Smithsonian faces a deadline to show Trump its plans for exhibits for America's 250th birthday

- Costa Rica's security director says plot to assassinate president uncovered

- Photos of demonstrators outside the Supreme Court as it considers upholding transgender sports bans

China flu activity declines for fourth week, no new pathogens detected: official

- Chinese commerce chambers welcome latest development in China-EU EV talks

- China opens 2026 space mission schedule with successful satellite launch

- Palestinian death toll in Gaza rises to 71,424: health authorities

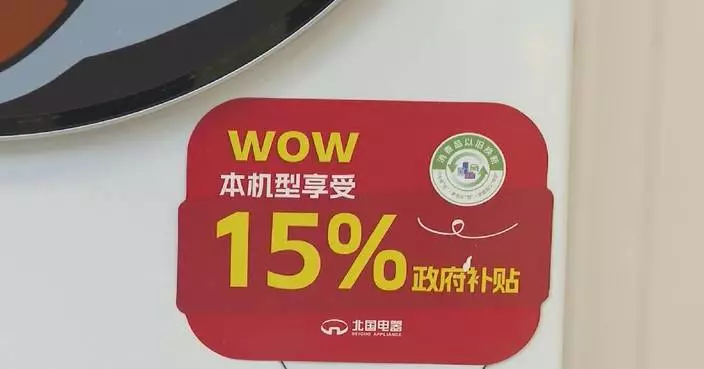

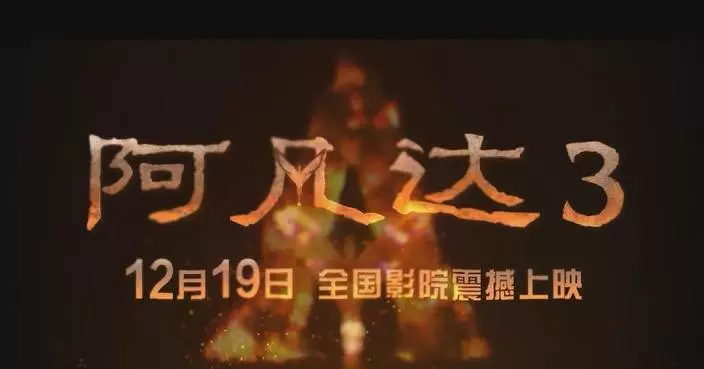

- China's box office revenue for commercial performances hits 61.66 bln yuan in 2025

- Xi's special envoy visits Laos

- Iranians in Türkiye return home, fearing for their families amid unrest in Iran

- UBS forecasts 8 pct growth in China's equity market for 2026

- Iranians in China hope for quick resolution to unrest, urge against foreign interference

- Heavy snowfall blankets Serbia, disrupting power supply, transportation

Wall Street executives warn Trump: Stop attacking the Fed and credit card industry

- Nurses strike enters second day at major New York City hospitals

- Trump visits a Ford pickup truck factory, aiming to promote his efforts to boost manufacturing

- Bargain grocer Aldi seizes the moment in an era of higher prices

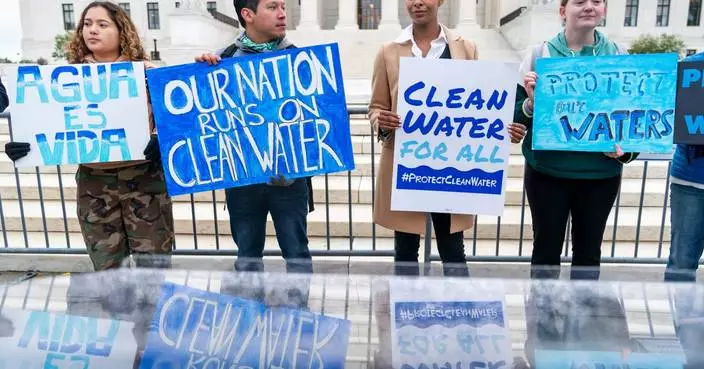

- EPA proposes limiting power of states and tribes to block major projects over water concerns

- TCL Note A1 NXTPAPER Achieves Multiple Awards at CES and Launches Pre-sale, Redefining the E-Note Experience

- MGallery Collection Steps Into 2026 With New and Exciting Destinations

- SiriusXM rehires Chris Cuomo to host morning talk show

- WIRobotics Concludes CES 2026, Advancing into Execution Phase of Global Collaboration Across Humanoid and Wearable Robotics

- FPT Establishes FPT Israel, Reinforcing Its Commitment to Mastering Core Technologies and Elevating Vietnam's Global Tech Position

Death toll from Iranian protests surpasses 2,000, activists say, as chaos recalls 1979 revolution

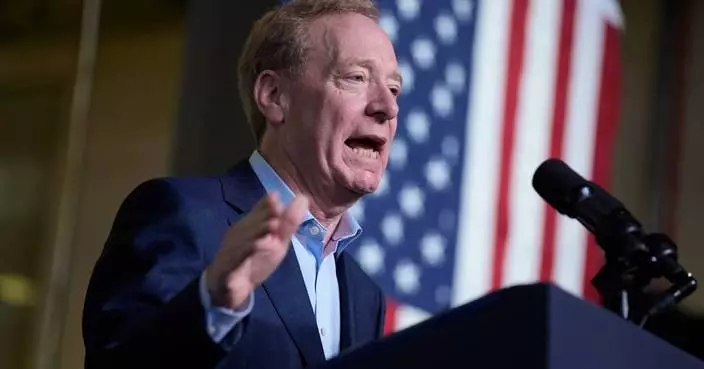

- Microsoft's Brad Smith pushes Big Tech to 'pay our way' for AI data centers amid rising opposition

- Malaysia will take legal action against Musk's X and xAI over misuse of Grok chatbot

- Pentagon is embracing Musk's Grok AI chatbot as it draws global outcry

- Apple calls on Google to help smarten up Siri and bring other AI features to the iPhone

- Meta names former Trump adviser Dina Powell McCormick as president and vice chairman

- Malaysia and Indonesia become the first countries to block Musk’s Grok over sexualized AI images

- Google teams up with Walmart and other retailers to enable shopping within Gemini AI chatbot

- VR headsets are 'hope machines' inside California prisons, offering escape and practical experience

- Doctors say changes to US vaccine recommendations are confusing parents and could harm kids

National Board of Review to fete 'One Battle After Another'

- Snoop Dogg's NBA analyst role underscores why his on-air presence and global appeal keeps growing

- Scott Adams, whose comic strip 'Dilbert' ridiculed white-collar office life, dies at 68

- The BBC seeks to dismiss Trump's $10B defamation lawsuit in a Florida court

- Hong Kong court moves closer to sentencing activist Jimmy Lai after hearing lighter penalty pleas

- Adelaide Writers Week canceled as 180 speakers withdraw after the exclusion of a Palestinian writer

- PBS weekend newscasts shut down due to funding cuts, replaced by single-topic programs

- 'Joe Dirt' tribute takes top prize in Pennsylvania Farm Show mullet contest

- Music honcho L.A. Reid settles with ex-recording executive who accused him of sexual assault

- Celebrities embrace black and old Hollywood glamour for Golden Globes red carpet

Mike Tomlin steps down after 19 seasons as coach of the Pittsburgh Steelers

- Eagles move on from OC Kevin Patullo after one lackluster season with him calling plays

- Manchester United hires former player Michael Carrick as head coach until end of the season

- Mikaela Shiffrin and US teammate Paula Moltzan finish 1-2 in Flachau night slalom

- Supreme Court seems likely to uphold state bans on transgender athletes in girls and women's sports

- Aubameyang, Manga reinstated after Gabon's post-Africa Cup expulsions, search for coach continues

- Chloe Kim says she's 'good to go' for Olympics despite labrum tear in shoulder

- Healthy and rested Rick Bowness ready for next challenge as Blue Jackets head coach

- Bears coach Ben Johnson offers no apologies for profane postgame speech

- Nartey's breakthrough goal gives Stuttgart a 3-2 win over Frankfurt in thriller

Court Dismisses Chow Hang Tung's Challenge to Hong Kong's Clothing Policy for Persons in Custody

- AFCD Cracks Down on Fraudulent Sales at FarmFest 2026, Considers Permanent Ban for Violators.

- SWD Celebrates Outstanding Carers at Hong Kong's Care the Carers Campaign Ceremony

- Go! Illustrators Finale Celebrates Emerging Hong Kong Picture Book Talent at International Book Fair

- Hong Kong Releases January Gravidtrap Indexes for Aedes Albopictus, Most Areas Report 0% Infestation.

- Hong Kong Records Serious Pollution Levels; Health Risks Alert Issued for Vulnerable Groups

- HKMA Warns Public About Fraudulent Banking Websites and Scams

- Hong Kong Reports No New Chikungunya Fever Cases Amid Ongoing Mosquito Control Efforts

- Contractor Suspended After Fatal Incident at Kai Tak Construction Site: DEVB Takes Action on Safety Compliance.

- Hong Kong Customs Cracks Down on Unlicensed Money Services via Social Media, Arresting 24 Individuals in 2025.

Economy remains primary issue as presidential election draws close in Uganda

- World’s largest-diameter boring machine put into use for Yangtze River railway tunnel

- Nigeria petrol price cuts ease living costs, raise durability concerns

- Chicago expands housing supply to ease affordability pressure

- Turpan City in Xinjiang hit by continuous heavy fog

- Traditional treatments, advanced equipment on China's navy hospital ship wow Brazilian visitors

- Cold wave triggers temperature dips, snowfall in northwest China's Xinjiang

- AI tennis robot serves as perfect practice partner for players in Shenzhen

- Former Fed chairs, US officials decry criminal probe against Jerome Powell

- Innovative technology breathes new life into centuries-old winter fishing tradition in northeast China's Jilin

Category · News

Tensions flare in Minnesota as protesters and federal agents repeatedly square off

Mike Tomlin steps down after 19 seasons as coach of the Pittsburgh Steelers

Attorneys give dueling narratives to open 'au pair affair' double murder trial in Virginia

Gaza's living conditions worsen as strong winds and hypothermia kill 5

‘Dances with Wolves’ actor Nathan Chasing Horse's child sex abuse trial begins

'West Wing' actor Timothy Busfield turns himself in to face child sex abuse charges in New Mexico

Trump administration labels 3 Muslim Brotherhood branches as terrorist organizations

Eagles move on from OC Kevin Patullo after one lackluster season with him calling plays

Wall Street pulls back from its records as JPMorgan Chase and Delta kick off earnings season

Armed Forces Benefit Association (AFBA) Appoints Larry O. Spencer Chair of the Board

Smithsonian faces a deadline to show Trump its plans for exhibits for America's 250th birthday

Costa Rica's security director says plot to assassinate president uncovered

Manchester United hires former player Michael Carrick as head coach until end of the season

Mikaela Shiffrin and US teammate Paula Moltzan finish 1-2 in Flachau night slalom

Photos of demonstrators outside the Supreme Court as it considers upholding transgender sports bans

Supreme Court seems likely to uphold state bans on transgender athletes in girls and women's sports

Aubameyang, Manga reinstated after Gabon's post-Africa Cup expulsions, search for coach continues

What to know about the warrants most immigration agents use to make arrests

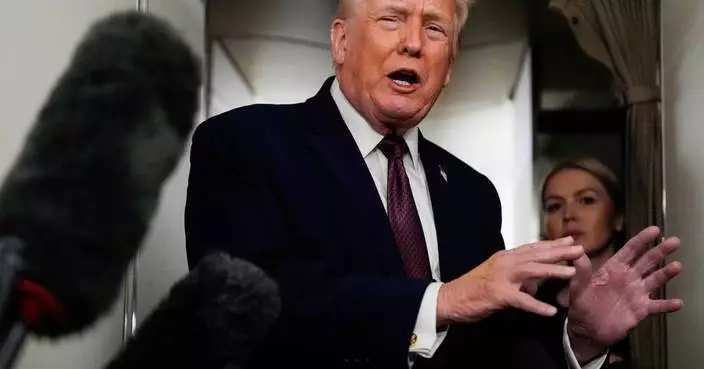

The Latest: Trump in Michigan to promote US manufacturing amid concerns about a weakening job market

A suspect in the vandalism of JD Vance’s Ohio home must stay in jail until trial

AFL Introduces Fujikura 100S Fusion Splicer with Dual-Fiber Technology and CT60 Cleaver

New Incisiv Study with Toshiba and Intel Explores How Adaptive Store Operations Balance Experience and Efficiency in Specialty Retail

FACT FOCUS: Trump repeats false claims when discussing Greenland's security in the Arctic

Chloe Kim says she's 'good to go' for Olympics despite labrum tear in shoulder

China flu activity declines for fourth week, no new pathogens detected: official

Immigrant detainee at 'Alligator Alcatraz' agrees to leave US, asks that lawsuit be dismissed

Healthy and rested Rick Bowness ready for next challenge as Blue Jackets head coach

Trump cancels meetings with Iranian officials and tells protesters 'help is on its way'

Hundreds more Venezuelans come forward to register relatives as 'political prisoners'

Ex-Navy SEAL convicted of planning to fire explosives at police during San Diego ‘No Kings’ rally

Bears coach Ben Johnson offers no apologies for profane postgame speech

Nartey's breakthrough goal gives Stuttgart a 3-2 win over Frankfurt in thriller

Wall Street executives warn Trump: Stop attacking the Fed and credit card industry

The Steelers are in NFL purgatory. They'll have to find a way out without Mike Tomlin

Creditors Are Leaving Money on the Table—Bankruptcy Accounts Still Hold Value

NYC Council employee’s arrest sparks protests and a dispute over his immigration status

Next-Generation TFX Thermoformer Sets New Benchmark in Speed and Flexibility for High-Volume Producers

Nurses strike enters second day at major New York City hospitals

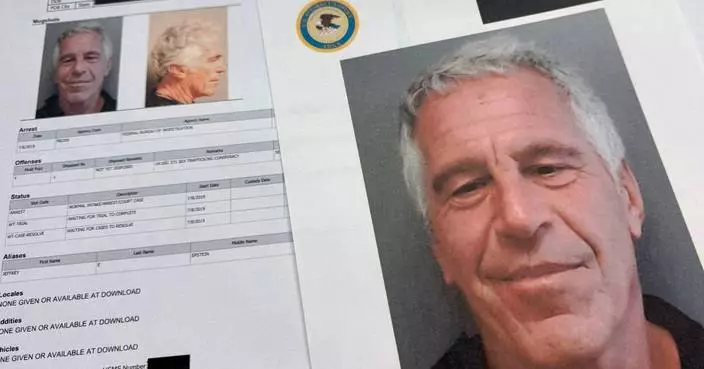

Clintons refuse to testify in House Epstein probe as Republicans threaten contempt proceedings

National Board of Review to fete 'One Battle After Another'

Trump visits a Ford pickup truck factory, aiming to promote his efforts to boost manufacturing

Bargain grocer Aldi seizes the moment in an era of higher prices

Matt Ryan is seeking to handle unfinished business in his new role as Falcons president of football

Leverkusen's Bundesliga game at Hamburg postponed over stadium roof concerns

EPA proposes limiting power of states and tribes to block major projects over water concerns

Diamondbacks acquire 8-time All-Star 3B Nolan Arenado in a deal with the Cardinals

The Latest: Iran eases some communications restrictions as activists say death toll spikes to 2,000

Death toll from Iranian protests surpasses 2,000, activists say, as chaos recalls 1979 revolution

Cherished Sierra Club Cabins Now Available to Book on Hipcamp for Winter

Marine Le Pen's appeal trial opens in Paris, with far-right leader's 2027 presidential bid at stake

Greenland official calls it 'unfathomable' that the US is considering taking over the island

Democrats will spend millions to shift voter registration strategy ahead of the midterm elections

South Korean prosecutor seeks death sentence for ex-leader Yoon over martial law decree

MGallery Collection Steps Into 2026 With New and Exciting Destinations

TCL Note A1 NXTPAPER Achieves Multiple Awards at CES and Launches Pre-sale, Redefining the E-Note Experience

Tearful Nebraska state Sen. McKeon resigns amid accusations of inappropriate behavior

Trump is ending protected immigration status for Somalis, long a target of his anti-immigrant barbs

Panthers GM says team will pick up QB Bryce Young's 5th year option, no timeline on extension

NFL's wild-card weekend was full of fourth-down fun and folly along with a dearth of punts

Snoop Dogg's NBA analyst role underscores why his on-air presence and global appeal keeps growing

Chicago among 5 Athletes Unlimited Softball League franchise locations announced for 2026 season

SiriusXM rehires Chris Cuomo to host morning talk show

Syrian army and Kurdish forces exchange strikes in an area near Aleppo

Chinese commerce chambers welcome latest development in China-EU EV talks

Tenneco Goes Live on QAD Adaptive, Accelerating Manufacturing Operations Modernization Across Global Operations

WIRobotics Concludes CES 2026, Advancing into Execution Phase of Global Collaboration Across Humanoid and Wearable Robotics

Man accused of recklessly driving U-Haul into Iran protest in Los Angeles, police say

Scott Adams, whose comic strip 'Dilbert' ridiculed white-collar office life, dies at 68

China opens 2026 space mission schedule with successful satellite launch

Wisconsin Gov. Evers questions his lieutenant governor's immigration enforcement proposal

Palestinian death toll in Gaza rises to 71,424: health authorities

Trump set to lead largest-ever US delegation to World Economic Forum in Davos next week

FPT Establishes FPT Israel, Reinforcing Its Commitment to Mastering Core Technologies and Elevating Vietnam's Global Tech Position

Roma leads Dakar Rally for first time since 2014 after navigation errors shake up race

VIVOTEK Chroma24 AI Cameras Unveil Night in True Color

Portugal defender João Cancelo returns to Barcelona on loan from Al-Hilal

Russia launches another major strike on Ukraine's power grid in freezing temperatures

JPMorgan Chase profits rise 9% in the fourth quarter excluding hit from the Apple Card acquisition

China's box office revenue for commercial performances hits 61.66 bln yuan in 2025

Inflation cooled slightly in December though it remains above Fed's target

David Webb, prominent Hong Kong shareholder activist, dies at 60

Brooks Koepka is back on the PGA Tour because it's better than leaving him off

TurningPoint Energy Welcomes Mike Marsch as Vice President of Development

Microsoft's Brad Smith pushes Big Tech to 'pay our way' for AI data centers amid rising opposition