Guizhou Province in southwest China has focused its efforts on the research and development of battery materials to better support the boom of new energy industry in the country.

Lithium iron phosphate batteries are widely used in new energy vehicles and energy storage due to their long service life, safety, wide source of raw materials, and low price.

Guizhou has rich phosphate resources and mature phosphorus chemical technology, and has supplied a large amount of iron phosphate, one of the most important raw materials for the production of lithium iron phosphate batteries, to battery manufacturers nationwide.

Founded in October 2022, the Guizhou New Energy Materials Innovation Center mainly focuses on the battery material industry chain. It has conducted research on core technologies and industrialization of research and development results.

Over the past few years, researchers here have tackled many challenges to optimize the flows of production process of critical chemicals required for the battery production.

For example, a set of continuous reaction crystallization equipment for iron phosphate, which is independently developed by the researchers, can now make the crystal shape and morphology of the product controllable and adjustable.

The researchers tried to directly make lithium iron phosphate batteries by combining iron phosphate with lithium and carbon sources, and conducted performance tests.

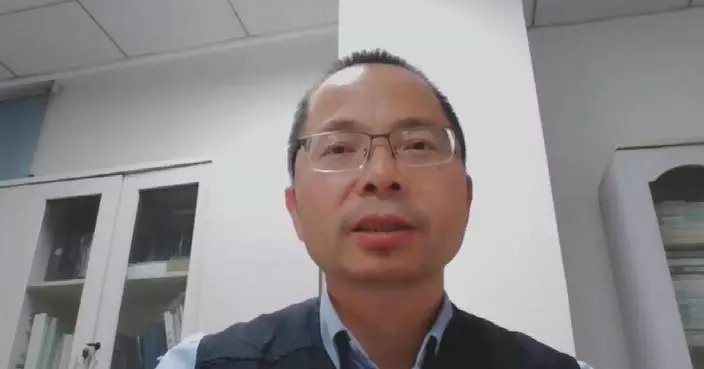

"In terms of capacity, the current theoretical value of lithium iron phosphate is 170. Now we can achieve 160 on our product. So basically we can say we have reached 90 percent of its potential performance," said Peng Hainan, a research and development engineer at the center.

At present, this set of equipment has already been applied to the production line. This close combination of research and production has injected momentum into the development of NEV industry in Guizhou.

The average life of current NEV batteries is five to eight years, which means a large number of batteries will retire in the coming years. It is crucial that these batteries are properly recycled.

At the Guizhou New Energy Materials Innovation Center, researchers have developed a unique wet phosphoric acid purification technology to successfully recover all elements such as phosphorus, iron, and lithium from retired batteries.

"Our wet process mainly uses lithium iron phosphate black powder as a raw material. We need to first add in acid, such as sulfuric acid, nitric acid, and hydrochloric acid. Then we leach out the lithium and iron elements and filter them. After filtering, we got the lithium sulfate solution. We need to add sodium carbonate in for precipitation to get our final product, lithium carbonate," said Yu Xinxin, a researcher of the center.

With the application of this technology, the recycling rate of lithium carbonate can reach 93 percent or above, which also provides strong support for the sustainable development of the new energy industry.

Innovative production of battery materials empowers China's new energy development