Feature · News

China's first city-level scenario-based public service platform starts operation in Nanjing

China mulls revision to Foreign Trade Law to boost digital, green trade

Power On. Connected. emnify Debuts Factory-First Instant Connectivity for IoT Devices at CES 2026

Thai villagers caught up in border clash take up night patrols to alert community against attacks

Northern China takes measures to address heavy snow's negative impact

CIIE-linked fair brings global goods directly to Chinese consumers

Judge allows Kilmar Abrego Garcia to remain free while she considers immigration issues

China's tourist destinations roll out creative scenarios to boost tourist arrivals

Live music performances become new consumption driver in China

Dried cherry scones are a simple treat for the post-holiday breakfast table

NSA employee sues Trump administration over order on transgender rights and two 'immutable' genders

China hopes ROK will handle submarine cooperation with U.S. with prudence: spokesman

Avangrid Foundation Announces National Partnership with Feeding America®

Car bomb kills Russian general in Moscow

The killing of a general in Moscow follows a series of assassinations Russia blames on Ukraine

Nielsen and Roku Expand Strategic Measurement Partnership

Judge allows Kilmar Abrego Garcia to remain free while she considers immigration issues

China's tourist destinations roll out creative scenarios to boost tourist arrivals

Live music performances become new consumption driver in China

Dried cherry scones are a simple treat for the post-holiday breakfast table

China's first city-level scenario-based public service platform starts operation in Nanjing

China mulls revision to Foreign Trade Law to boost digital, green trade

Power On. Connected. emnify Debuts Factory-First Instant Connectivity for IoT Devices at CES 2026

Thai villagers caught up in border clash take up night patrols to alert community against attacks

Northern China takes measures to address heavy snow's negative impact

CIIE-linked fair brings global goods directly to Chinese consumers

NSA employee sues Trump administration over order on transgender rights and two 'immutable' genders

China hopes ROK will handle submarine cooperation with U.S. with prudence: spokesman

Avangrid Foundation Announces National Partnership with Feeding America®

Car bomb kills Russian general in Moscow

The killing of a general in Moscow follows a series of assassinations Russia blames on Ukraine

Nielsen and Roku Expand Strategic Measurement Partnership

Feature·Bloggers

【Deep Blue】Trump's "Empire Strikes Back" Gambit: A Long Shot at Best

【What Say You?】Unfinished business With the “anti-Hong Kong triangle”?

【Bastille Commentary】UK's Hypocrisy on Display: Seizing Private Assets While Preaching Freedom

【What Say You?】London’s Selective Memory on National Security

【What Say You?】The “Shina-Implosion” Playbook Behind Jimmy Lai

【Ariel】Insider Breaks Silence: 2019 Was Orchestrated — And He Names Who Pulled the Strings

Powerball numbers drawn for $1.6B jackpot, but the odds still aren't in your favor

- US strikes another alleged drug-smuggling boat in eastern Pacific

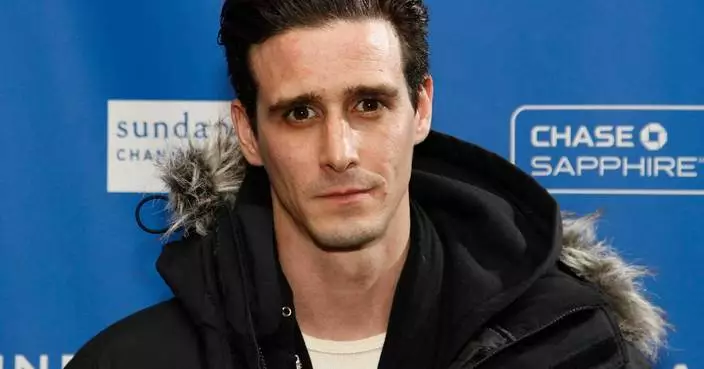

- Vince Zampella, video game pioneer behind Call of Duty, dies at 55

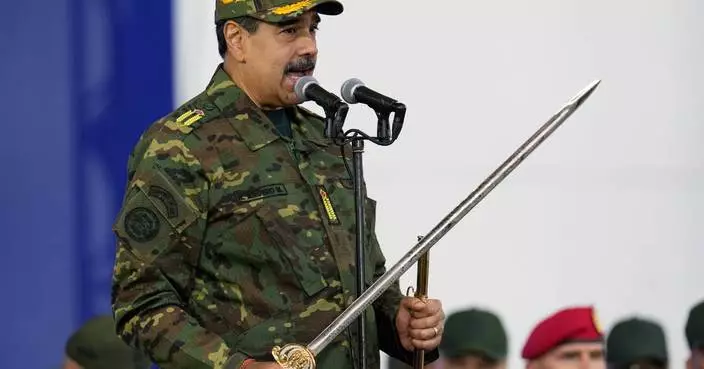

- Trump warns Maduro against playing 'tough' as US escalates pressure campaign on Venezuela

- At least 5 killed after Mexican Navy plane on medical mission crashes in Texas

- Takeaways from AP's report on a beef plant closure that threatens to unravel a small Nebraska town

- An American Dream at risk: What happens to a small Nebraska town when 3,200 workers lose their jobs

- Judge rules Trump administration must allow court challenges for Venezuelan migrants sent to prison

- Brown University police chief placed on leave after fatal shooting, feds launch investigation

- Canada's Prime Minister Carney names financier Mark Wiseman as the next ambassador to Washington

Chinese yuan strengthens to 7.0523 against USD Tuesday

- Crude futures settle higher

- U.S. dollar ticks down

- U.S. stocks close higher

- UN backs Thailand, Cambodia to de-escalate tensions through dialogue

- EU extends economic sanctions on Russia for another 6 months

- Russian, Venezuelan FMs voice concern over US actions in Caribbean

- HK's West Kowloon Station sees annual passenger flow exceed 30 million

- Russia captures one more settlement in Kharkiv, Ukraine reports power outages from Russian attacks

- China's top legislature convenes standing committee session

HICC Pet × Marina One - Mental Wellness Month: Healing Moments with Dogs at HICC Pet Showroom

- Xinhua Silk Road: Hainan FTP vows to further optimize business environment

- Yindii Turns Food Waste Into Value, Saving 500,000+ Meals in 2025

- Rescuing Meals, Rewriting Waste: Yindii Closes 2025 With Over Half a Million Meals Saved

- Agoda Insights Reveal Business Impact of Localization Across Asia's Rapidly Growing Tourism Sector

- Hualien New Year's Countdown Party Kicks Off Taiwan's Year-End Festivities and Winter Travel Season

- MILLENNIUM HOTELS & RESORTS AND IHCL JOIN HANDS ON A GLOBAL LOYALTY PARTNERSHIP

- Changzhou Invites the Public to Explore the City Through Culture

- Discovering Lianyungang: A City Shaped by Mountains and Sea

- Zenith Yacht Charters Expands Into Yacht Brokerage With New Platform Zenith Yachting Asia

US regulators approve Wegovy pill for weight loss

- Waymos blocked roads and caused chaos during San Francisco power outage

- US signs new health deals with 9 African countries that mirror Trump's priorities

- Italy antitrust agency fines Apple $116 million over privacy feature; Apple announces appeal

- What's an atmospheric river? AP explains the weather phenomenon

- Addiction-stricken community struggles to keep a syringe program going after Trump's order

- Starlink in the crosshairs: How Russia could attack Elon Musk's conquering of space

- Instacart ends a program where users could see different prices for the same item at the same store

- Japan's new flagship H3 rocket fails to put geolocation satellite into orbit

- The rise of deepfake cyberbullying poses a growing problem for schools

Barry Manilow has early-stage lung cancer and will undergo surgery

- '60 Minutes' pulls story about Trump deportations from its lineup

- Banksy unveils new art in London following speculation over murals depicting stargazing figures

- Golden Gate Park's dazzling holiday light display brings joy to the season

- Larry Ellison guarantees $40.4 billion in Paramount's hostile bid for Warner Bros. Discovery

- Singer-songwriter Chris Rea, known for 'Driving Home for Christmas,' dies at 74

- Pop culture in 2025: A ring for Taylor, an ill-timed KissCam ... and whatever ‘6-7’ means

- The Grammys split the country album category into traditional and contemporary. It might be great

- Turkey shoot a holiday tradition, with no ruffled feathers

- Giant lazy Susans bring people together at Mississippi restaurant

Zion Williamson scores 24 to lead Pelicans over Mavericks for 5th straight win

- Grebenkin, Grundstrom lead Flyers to 5-2 win over Canucks

- Top photos from Week 16 of the NFL season

- Jaylen Brown scores 31 points as Celtics rally past Pacers 103-95

- Mitchell scores 30 points as the Cavaliers beat the Hornets 139-132 to end a 3-game losing streak

- Raddysh has goal, 2 assists to reach 100 career points as Lightning beat Blues 4-1

- Phillies sign reliever Zach Pop to 1-year deal

- Raiders' potential draft dilemma: Winning games could cost them a chance at a franchise QB

- As Jordan and Hill approach career crossroads, they're helping the rebuilding Saints win again

- Jorge Polanco, with 1 pitch of first base experience, willing to make move for New York Mets

New Mercury Control Ordinance Takes Effect December 2025, Banning Harmful Products to Protect Public Health

- Judiciary Expands E-Appointment Services for Distress Warrants Starting December 30

- Inmate Found Unconscious in Lai Chi Kok Dies in Hospital; Coroner's Inquest Scheduled

- Special Traffic Arrangements in Happy Valley for Race Day Today

- Pest Control Committee Reviews Chikungunya Prevention and 2026 Plans for Mosquito and Rodent Control Efforts

- Government Launches Task Forces to Support Wang Fuk Court Fire Victims with Financial Aid and Relief Services

- Four new Legionnaires' disease cases reported; public urged to maintain water systems and follow health precautions

- Environmental Director Inspects Major Water Quality Improvements in Tsuen Wan, Kwai Tsing, and Sham Shui Po

- Hong Kong Park Opens as Key Innovation Hub in Hetao Cooperation Zone

- Stay Healthy This Holiday: Get Vaccinated and Practice Hygiene to Avoid Infectious Diseases

Hainan FTP launches first air route under seventh-freedom traffic right

- Xi presents orders to promote two military officers to rank of general

- New plan launched to expedite clearance, licensing for NEVs in Hong Kong

- Foreign enterprises accelerate investment in Hainan Free Trade Port

- Construction of Bailong nuclear power plant's main structure begins

- China slaps tariffs on EU dairy products following anti-subsidy investigations: officials

- VEX Robotics Asia Open concludes with global participation

- Hong Kong stocks close 0.43 pct higher

- Chinese shares close higher Monday

- Residents, tourists enjoy winter sports in China

Category · News

Powerball numbers drawn for $1.6B jackpot, but the odds still aren't in your favor

HICC Pet × Marina One - Mental Wellness Month: Healing Moments with Dogs at HICC Pet Showroom

US strikes another alleged drug-smuggling boat in eastern Pacific

Vince Zampella, video game pioneer behind Call of Duty, dies at 55

New Mercury Control Ordinance Takes Effect December 2025, Banning Harmful Products to Protect Public Health

Zion Williamson scores 24 to lead Pelicans over Mavericks for 5th straight win

Trump warns Maduro against playing 'tough' as US escalates pressure campaign on Venezuela

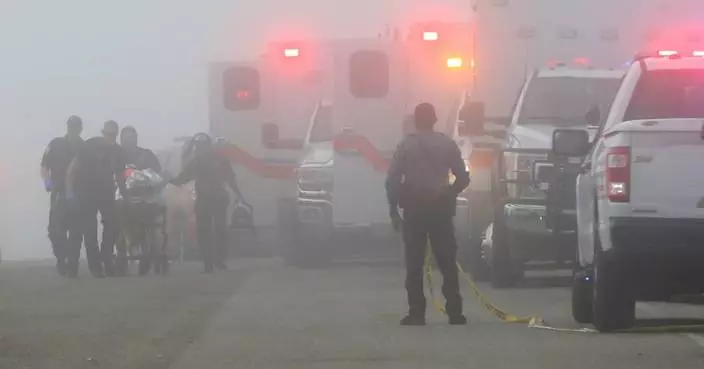

At least 5 killed after Mexican Navy plane on medical mission crashes in Texas

Grebenkin, Grundstrom lead Flyers to 5-2 win over Canucks

Xinhua Silk Road: Hainan FTP vows to further optimize business environment

Top photos from Week 16 of the NFL season

Yindii Turns Food Waste Into Value, Saving 500,000+ Meals in 2025

Rescuing Meals, Rewriting Waste: Yindii Closes 2025 With Over Half a Million Meals Saved

Agoda Insights Reveal Business Impact of Localization Across Asia's Rapidly Growing Tourism Sector

Jaylen Brown scores 31 points as Celtics rally past Pacers 103-95

Chinese yuan strengthens to 7.0523 against USD Tuesday

Hualien New Year's Countdown Party Kicks Off Taiwan's Year-End Festivities and Winter Travel Season

Judiciary Expands E-Appointment Services for Distress Warrants Starting December 30

Crude futures settle higher

Mitchell scores 30 points as the Cavaliers beat the Hornets 139-132 to end a 3-game losing streak

U.S. dollar ticks down

U.S. stocks close higher

MILLENNIUM HOTELS & RESORTS AND IHCL JOIN HANDS ON A GLOBAL LOYALTY PARTNERSHIP

Raddysh has goal, 2 assists to reach 100 career points as Lightning beat Blues 4-1

Changzhou Invites the Public to Explore the City Through Culture

Discovering Lianyungang: A City Shaped by Mountains and Sea

Zenith Yacht Charters Expands Into Yacht Brokerage With New Platform Zenith Yachting Asia

Takeaways from AP's report on a beef plant closure that threatens to unravel a small Nebraska town

An American Dream at risk: What happens to a small Nebraska town when 3,200 workers lose their jobs

Judge rules Trump administration must allow court challenges for Venezuelan migrants sent to prison

Columbia Asia Hospital Cheras Marks 15th Anniversary with Expansion, Wins MPRA 2025 Silver Award for Best Use of Content

Phillies sign reliever Zach Pop to 1-year deal

OutSystems Announces the Successful Completion of "AI Agent Hackathon 2025" Showcasing AI-Powered Low-Code

Amorepacific Museum of Art Announces 2026 Exhibition Program

Brown University police chief placed on leave after fatal shooting, feds launch investigation

Raiders' potential draft dilemma: Winning games could cost them a chance at a franchise QB

Inmate Found Unconscious in Lai Chi Kok Dies in Hospital; Coroner's Inquest Scheduled

As Jordan and Hill approach career crossroads, they're helping the rebuilding Saints win again

UN backs Thailand, Cambodia to de-escalate tensions through dialogue

SDS Australia Unveils Luxury Sauna as Exclusive European Partnership Enters Second Year

EU extends economic sanctions on Russia for another 6 months

Russian, Venezuelan FMs voice concern over US actions in Caribbean

THE KYLN HOTEL SUZHOU CELEBRATES GRAND OPENING, JOINING THE JDV BY HYATT BRAND

Canada's Prime Minister Carney names financier Mark Wiseman as the next ambassador to Washington

Judge accepts plea deals from Colorado funeral home owners who acknowledged abusing 191 corpses

Special Traffic Arrangements in Happy Valley for Race Day Today

Three More Coway Airmega Air Purifiers Approved by Sensitive Choice for Australians with Allergies and Asthma

LG Display unveils world's first 240Hz RGB stripe OLED panel

Sincere Healthcare Group and Landmark Medical Centre Unite to Strengthen Cross-Border Patient Care Between Singapore and Johor Bahru

Jorge Polanco, with 1 pitch of first base experience, willing to make move for New York Mets

Lions facing long playoff odds after losing 2 straight games for 1st time since 2022

21 Democratic-led states sue White House over consumer protection bureau funding

Seattle Mariners sign outfielder Rob Refsnyder to 1-year contract

Carlisle to step down, Bickerstaff to become National Basketball Coaches Association president

Browns beset by injuries on offense while still trying to evaluate Shedeur Sanders

Trump's appointment of envoy to Greenland sparks new tension with Denmark

Trump announces plans for new Navy 'battleship' as part of a 'Golden Fleet'

Kansas City Chiefs announce they will leave Arrowhead and relocate across the Kansas-Missouri border

US regulators approve Wegovy pill for weight loss

Workers organized by a key union rally in Bolivia against scrapping fuel subsidies

FCC bans new Chinese-made drones, citing security risks

Colts activate Pro Bowl DT DeForest Buckner for a crucial Monday night game against the 49ers

Sprinkles (HK) Charity Foundation Donates to The Education University of Hong Kong to Promote "Harmony between Humanity and Nature Sustainable Education" Project

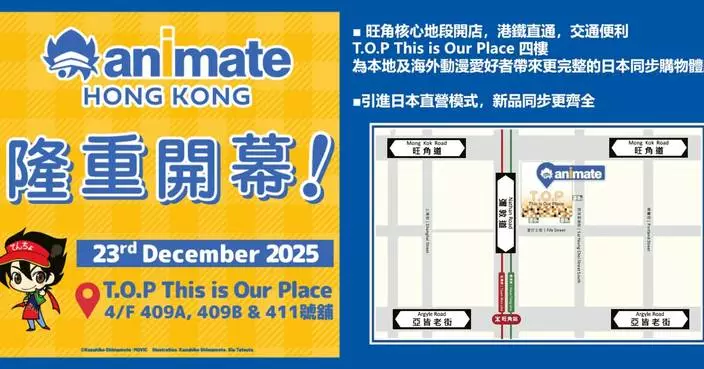

Japan's Largest Anime Specialty Store Lands in Hong Kong - Animate Hong Kong's Mong Kok Direct Store Officially Opens Today

Mets jettison Jeff McNeil in trade to A's following departures of Alonso, Nimmo and Díaz

Latest batch of Cardinals injuries could have long-lasting effects

Ukraine's Zelenskyy says progress in US-led peace talks is 'quite solid'

Brady Cook getting third straight start for Jets against Patriots in home finale

Playoff-bound Patriots are on the verge of an AFC East title. They also have injury concerns

Salah scores Egypt's late winner to beat Zimbabwe 2-1 in Africa Cup

Chiefs' move to Kansas leaves Missouri fans heartbroken over another NFL franchise leaving

Champion® Homes and iUnit Communities Celebrate Ribbon Cutting of the Innovation Cottages, Showcasing Energy Efficient Capabilities of Offsite-Built Homes

FINALS, SEMI-FINALS AND NON-STOP ACTION AS GOTF 2025 REACHES CLIMAX

Chargers will need to sustain offensive progress from win over Cowboys to be Super Bowl contenders

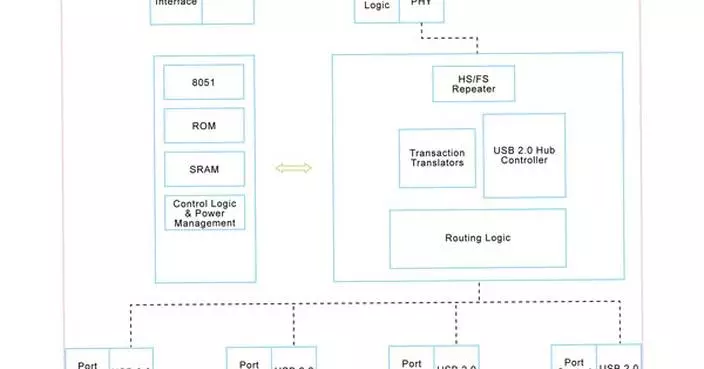

VIA Labs Expands Connectivity Portfolio with New Line of Industrial-Grade USB Hub Controllers

Walker & Dunlop Arranges Sale and Financing for Cambridge Multifamily Asset

White House rebuffs Catholic bishops' appeal for a Christmas pause in immigration enforcement

Mercedes-Benz agrees to pay $149.6 million to settle multistate emissions allegations

QB Bryce Young's turnaround boosts Panthers' playoff hopes

Flash flooding in northern California leads to soaked roads, water rescues and 1 death

Steelers WR DK Metcalf suspended 2 games following altercation with fan in Detroit

Colombia will use drones to destroy coca crops as it grapples with record cocaine production

Barry Manilow has early-stage lung cancer and will undergo surgery

Dhanarak Asset Development Unveils Thailand’s First Green Government City at Government Complex Bangkok