Feature · News

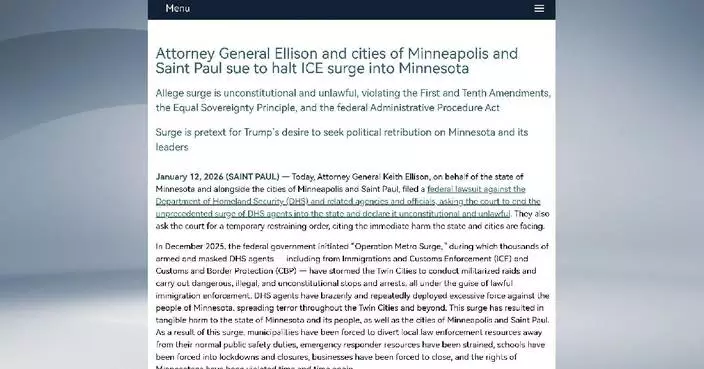

Minnesota, Illinois sue Trump administration over surge of federal immigration enforcement

AI-powered service platforms improve consumer experiences in China

China welcomes foreign enterprises, long-term capital to continue expanding investment in China: vice premier

Iran's nationwide demonstrations oppose U.S., Israel interference

HK Express Soars as World's Safest Budget Airline Again

Trump holds off on military action against Iran's protest crackdown as he 'explores' Tehran messages

BP China Insight : Trump's Actions Have Turned the EU into an Outdated Relic of History

BP China Insight : Beijing Strikes Back at Meta's "Grab Tech and Talent" Acquisition

China issues new regulation to guide development of gov't investment funds

Chinese yuan hits 32-month high against US dollar

Mississippi man accused of killing 6 people, including a 7-year-old, pleads not guilty

Court says Trump admin illegally blocked billions in clean energy grants to Democratic states

What to know about the Chicago doctor charged with murdering his ex-wife and her husband

FBI says it has found no video of Border Patrol agent shooting 2 people in Oregon

Colombian rebels call for a 'national accord' after the US intervention in Venezuela

$182M settlement reached in 2015 commuter train crossing crash that killed 6 in New York

BP China Insight : Trump's Actions Have Turned the EU into an Outdated Relic of History

BP China Insight : Beijing Strikes Back at Meta's "Grab Tech and Talent" Acquisition

China issues new regulation to guide development of gov't investment funds

Chinese yuan hits 32-month high against US dollar

Minnesota, Illinois sue Trump administration over surge of federal immigration enforcement

AI-powered service platforms improve consumer experiences in China

China welcomes foreign enterprises, long-term capital to continue expanding investment in China: vice premier

Iran's nationwide demonstrations oppose U.S., Israel interference

HK Express Soars as World's Safest Budget Airline Again

Trump holds off on military action against Iran's protest crackdown as he 'explores' Tehran messages

Mississippi man accused of killing 6 people, including a 7-year-old, pleads not guilty

Court says Trump admin illegally blocked billions in clean energy grants to Democratic states

What to know about the Chicago doctor charged with murdering his ex-wife and her husband

FBI says it has found no video of Border Patrol agent shooting 2 people in Oregon

Colombian rebels call for a 'national accord' after the US intervention in Venezuela

$182M settlement reached in 2015 commuter train crossing crash that killed 6 in New York

Feature·Bloggers

【Deep Blue】International Laws? You Kidding Me?

【What Say You?】The Gavel vs. The Sanction: Hong Kong’s Judiciary Stands Firm

【Bastille Commentary】Chicken-hearted Conservatives: Sanctioning Hong Kong Judges While Trump Runs Wild

【What Say You?】Trump’s “Maduro Grab” Gets a Glossy Spin by the Usual Suspects

【What Say You?】Trump's Judicial Theater: Maduro's Fate Already Sealed

【Deep Throat】Trump's Venezuelan Oil Grab: Big Oil Not Playing Along?

Russia launches another major attack on Ukraine's power grid and other sites, killing 4

- The Latest: Iran eases some restrictions, allows calls abroad as death toll spikes

- People inside Iran describe heavy security and scattered damage in first calls to outside world

- French farmers drive 350 tractors to Parliament to protest low incomes and EU trade deal

- Venus Williams loses in 1st round of Australian Open tuneup event in Hobart

- Adelaide Writers Week canceled as 180 speakers withdraw after the exclusion of a Palestinian writer

- Consumer prices likely stayed elevated in December as data recovers from shutdown

- FPT Becomes Vietnam’s First Company to Achieve ISO/IEC 42001:2023 AI Management System Accredited Certification

- Tensions flare in Minnesota as protesters and federal agents repeatedly square off

- Former Apple Daily staff plead for lighter sentences in landmark Hong Kong national security case

Chicago expands housing supply to ease affordability pressure

- Takaichi's erroneous remarks push Japan toward war, violate constitution: expert

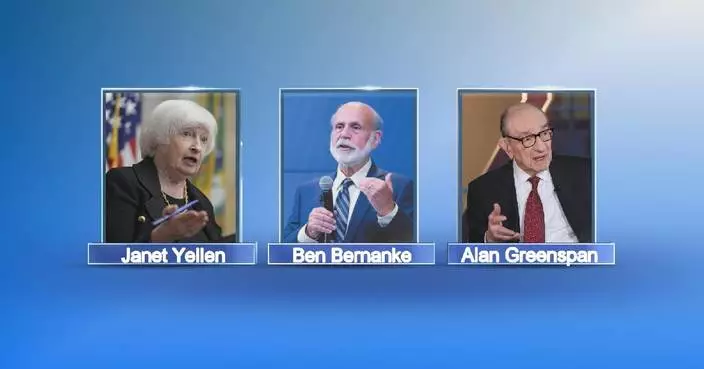

- Former Fed chairs, US officials decry criminal probe against Jerome Powell

- U.S. State Department revokes over 100,000 visas in 2025

- Hong Kong stocks close higher

- Hainan's Sanya opens first national dental specialty center

- Tender moments of playful new born panda cubs with caretaker captured in video footage

- Chinese envoy calls for peace, dialogue, unity on Ukraine issue

- Brazil in midst of heatwave with more extreme temperatures expected

- Xinjiang's Horgos Port sees record-breaking cross-border passenger flows in 2025

APh ePower Secures 2025 R&D 100 Award for Pioneering Elevator Energy Recovery

- ZTE Recognized on CDP Climate A List for Third Consecutive Year, Ranking Among the Global Top 4%

- ER-VIPE Simulation Game Builds Medical Students' Soft Skillsfor Real-World Emergency Care

- Huawei Releases Top 10 Trends of Smart PV & ESS 2026

- HTX Launches SunPump Ecosystem Trading Competition Round 2, Offering a 10,000 USDT Prize Pool

- Swiss-Belhotel International Strengthens Africa Portfolio with the Launch of The Gama by Swiss-Belhotel, Kilimani, Nairobi

- Rhenus Group awarded EcoVadis Platinum Medal, placing in the top 1% globally

- Ready Server Announces Strategic Expansion into Japan with AT TOKYO Data Centre

- Trump will visit a Ford factory and promote manufacturing in Detroit

- DoxAI Appoints Former Macquarie Capital Executive Roberto Purcaro to its Board of Directors to Accelerate Global Expansion

Pentagon is embracing Musk's Grok AI chatbot as it draws global outcry

- Apple calls on Google to help smarten up Siri and bring other AI features to the iPhone

- Meta names former Trump adviser Dina Powell McCormick as president and vice chairman

- Malaysia and Indonesia become the first countries to block Musk’s Grok over sexualized AI images

- Google teams up with Walmart and other retailers to enable shopping within Gemini AI chatbot

- VR headsets are 'hope machines' inside California prisons, offering escape and practical experience

- Doctors say changes to US vaccine recommendations are confusing parents and could harm kids

- Strength training is crucial after menopause. How to make the most of your workouts

- Meta lines up massive supply of nuclear power to energize AI data centers

- From climbing vacuums to cyber pets: Some highlights of CES 2026

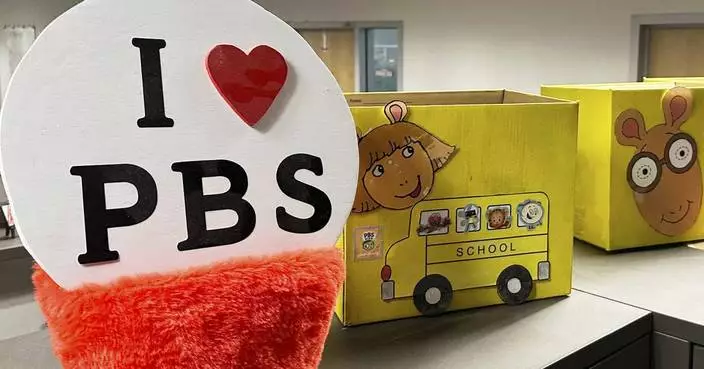

PBS weekend newscasts shut down due to funding cuts, replaced by single-topic programs

- 'Joe Dirt' tribute takes top prize in Pennsylvania Farm Show mullet contest

- Music honcho L.A. Reid settles with ex-recording executive who accused him of sexual assault

- Celebrities embrace black and old Hollywood glamour for Golden Globes red carpet

- Milan prison hosts concert with instruments made by inmates from migrant smugglers’ boats

- Celebrity birthdays for the week of Jan. 18-24 includes Mariska Hargitay and Dolly Parton

- Inside the Golden Globes: The reunions and moments the telecast didn't show

- Photos of 20-year-olds gathering in kimonos for Coming of Age Day ceremony in Japan

- See top photos of stars on the 2026 Golden Globe Awards red carpet

- Golden Globe highlights: Brazil on a streak, Amy Poehler's pod wins and Seth Rogen comes full-circle

Two more Russian athletes approved for Milan Cortina Olympics with neutral status

- Gael Monfils loses in 1st round in Auckland in likely his farewell season

- NFL's wild-card weekend was full of fourth-down fun and folly along with a dearth of punts

- Clippers star James Harden passes Shaquille O'Neal for 9th place on the NBA's all-time scoring list

- Mike Tomlin and the Steelers face familiar questions after their latest early playoff exit

- Keyonte George shines as Jazz defeat Cavaliers 123-112

- Leonard scores 35, Harden moves to 9th place on NBA's scoring list as Clippers beat Hornets 117-109

- Kraken rally from 2 goals down and beat Rangers 4-2

- William Nylander's OT goal gives Leafs 4-3 victory, snaps Avalanche's 17-game home win streak

- Texans stifle Aaron Rodgers and the Steelers 30-6 for franchise's 1st road playoff win

Hong Kong Records Serious Pollution Levels; Health Risks Alert Issued for Vulnerable Groups

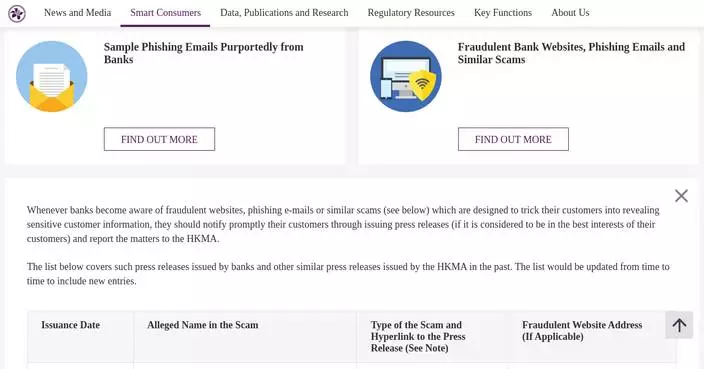

- HKMA Warns Public About Fraudulent Banking Websites and Scams

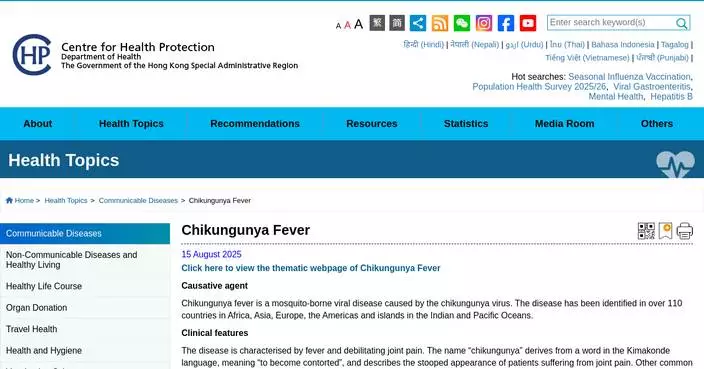

- Hong Kong Reports No New Chikungunya Fever Cases Amid Ongoing Mosquito Control Efforts

- Contractor Suspended After Fatal Incident at Kai Tak Construction Site: DEVB Takes Action on Safety Compliance.

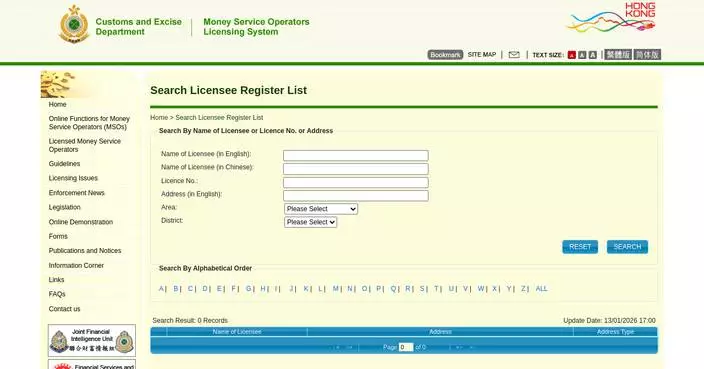

- Hong Kong Customs Cracks Down on Unlicensed Money Services via Social Media, Arresting 24 Individuals in 2025.

- SMEs' Business Sentiment Improves in December 2025, Shows Monthly Survey Results

- Luminara Makes Inaugural Arrival in Hong Kong, Boosting Cruise Tourism

- Hong Kong Customs Launches Campaign Against Illicit Cigarettes, Promotes New Duty Stamp System and Increased Penalties.

- Government Announces Senior Appointments in Civil Service and Other Departments for 2026

- Man Sentenced to Six Months for Smuggling $258,300 in Duty-Not-Paid Cigarettes at Hong Kong Airport

UN chief urges diplomacy amid US military threats against Iran: spokesperson

- China-EU agreement on price undertaking guidance for EV exports to stabilize supply chains: analyst

- Gold, silver prices climb to record highs on Monday

- Chinese yuan strengthens to 7.0103 against USD Tuesday

- U.S. dollar ticks down

- Somalia revokes all pacts with UAE amid diplomatic rifts

- Russia reports strikes on Ukrainian energy, transportation facilities; Ukraine claims repelling Russian attacks

- Cuban president denies dialogue with US, reaffirms willingness to negotiate

- Mossad agents attempt to direct terrorist acts: Iranian FM

- China, Canada should leverage complementarity for mutual benefit: former Canadian PM

Category · News

Hong Kong Records Serious Pollution Levels; Health Risks Alert Issued for Vulnerable Groups

Russia launches another major attack on Ukraine's power grid and other sites, killing 4

The Latest: Iran eases some restrictions, allows calls abroad as death toll spikes

HKMA Warns Public About Fraudulent Banking Websites and Scams

Hong Kong Reports No New Chikungunya Fever Cases Amid Ongoing Mosquito Control Efforts

Contractor Suspended After Fatal Incident at Kai Tak Construction Site: DEVB Takes Action on Safety Compliance.

Chicago expands housing supply to ease affordability pressure

Takaichi's erroneous remarks push Japan toward war, violate constitution: expert

Former Fed chairs, US officials decry criminal probe against Jerome Powell

People inside Iran describe heavy security and scattered damage in first calls to outside world

Hong Kong Customs Cracks Down on Unlicensed Money Services via Social Media, Arresting 24 Individuals in 2025.

U.S. State Department revokes over 100,000 visas in 2025

Hong Kong stocks close higher

Two more Russian athletes approved for Milan Cortina Olympics with neutral status

SMEs' Business Sentiment Improves in December 2025, Shows Monthly Survey Results

French farmers drive 350 tractors to Parliament to protest low incomes and EU trade deal

Venus Williams loses in 1st round of Australian Open tuneup event in Hobart

Hainan's Sanya opens first national dental specialty center

Luminara Makes Inaugural Arrival in Hong Kong, Boosting Cruise Tourism

Gael Monfils loses in 1st round in Auckland in likely his farewell season

NFL's wild-card weekend was full of fourth-down fun and folly along with a dearth of punts

Adelaide Writers Week canceled as 180 speakers withdraw after the exclusion of a Palestinian writer

APh ePower Secures 2025 R&D 100 Award for Pioneering Elevator Energy Recovery

Hong Kong Customs Launches Campaign Against Illicit Cigarettes, Promotes New Duty Stamp System and Increased Penalties.

Government Announces Senior Appointments in Civil Service and Other Departments for 2026

ZTE Recognized on CDP Climate A List for Third Consecutive Year, Ranking Among the Global Top 4%

ER-VIPE Simulation Game Builds Medical Students' Soft Skillsfor Real-World Emergency Care

Consumer prices likely stayed elevated in December as data recovers from shutdown

Tender moments of playful new born panda cubs with caretaker captured in video footage

Huawei Releases Top 10 Trends of Smart PV & ESS 2026

Chinese envoy calls for peace, dialogue, unity on Ukraine issue

Brazil in midst of heatwave with more extreme temperatures expected

FPT Becomes Vietnam’s First Company to Achieve ISO/IEC 42001:2023 AI Management System Accredited Certification

Xinjiang's Horgos Port sees record-breaking cross-border passenger flows in 2025

Clippers star James Harden passes Shaquille O'Neal for 9th place on the NBA's all-time scoring list

Man Sentenced to Six Months for Smuggling $258,300 in Duty-Not-Paid Cigarettes at Hong Kong Airport

UN chief urges diplomacy amid US military threats against Iran: spokesperson

Mike Tomlin and the Steelers face familiar questions after their latest early playoff exit

HTX Launches SunPump Ecosystem Trading Competition Round 2, Offering a 10,000 USDT Prize Pool

China-EU agreement on price undertaking guidance for EV exports to stabilize supply chains: analyst

Keyonte George shines as Jazz defeat Cavaliers 123-112

Leonard scores 35, Harden moves to 9th place on NBA's scoring list as Clippers beat Hornets 117-109

Kraken rally from 2 goals down and beat Rangers 4-2

Japan's 10-year gov't bond yield hits 27-year high: media

William Nylander's OT goal gives Leafs 4-3 victory, snaps Avalanche's 17-game home win streak

Venezuelan schools resume after US attacks

Tensions flare in Minnesota as protesters and federal agents repeatedly square off

Swiss-Belhotel International Strengthens Africa Portfolio with the Launch of The Gama by Swiss-Belhotel, Kilimani, Nairobi

Gold, silver prices climb to record highs on Monday

Former Apple Daily staff plead for lighter sentences in landmark Hong Kong national security case

Rhenus Group awarded EcoVadis Platinum Medal, placing in the top 1% globally

Texans stifle Aaron Rodgers and the Steelers 30-6 for franchise's 1st road playoff win

Jason Robertson strikes late in the third period to help send Stars to 3-1 victory over Kings

Monk hits 7 3-pointers, scores 26 points as Kings top Lakers 124-112; Doncic scores 42 in loss

Commercial recoverable spacecraft completes suborbital test flight in China

No. 1 Indiana, No. 10 Miami should be near full strength for national championship game

Ready Server Announces Strategic Expansion into Japan with AT TOKYO Data Centre

Families of prisoners in Venezuela wait in anguish as promised releases trickle

Bureau of Dangerous Goods Announces Updated Hazmat University Online Training Courses for 2026

Epirus Bank Selects NCR Atleos to Modernize and Expand ATM Network Across Greece

Trump will visit a Ford factory and promote manufacturing in Detroit

Blackhawks forward Connor Bedard misses loss to Oilers because of an illness

Former Navy sailor sentenced to 16 years for selling information about ships to Chinese intelligence

Texans, Patriots, 49ers, Bills, Bears and Rams advance to NFL's divisional round

McDavid and Bouchard help the Oilers beat the Blackhawks 4-1

Flagg posts 27 points, 3 steals to help Mavericks beat the Nets 113-105

DoxAI Appoints Former Macquarie Capital Executive Roberto Purcaro to its Board of Directors to Accelerate Global Expansion

Former Raptors star Kyle Lowry gets huge ovation in four-quarter cameo as 76ers win in Toronto

The Blind Sailor Takes the Stage at WEF: "HIRO’s CHOICE" Project to Set Sail

HKMA Announces Notes Exchange for Chinese New Year from February 3 to 16, Encourages Electronic Lai-See.

Titans continue coaching search with interview of former Falcons coach Raheem Morris, AP source says

Hong Kong Customs Seizes $4.8 Million in Suspected Counterfeit Goods at Airport

Jesper Bratt, Ondrej Palat each score 2 goals as Devils beat Wild 5-2 to snap four-game skid

U.S. stocks close higher amid criminal probe into Fed chair Powell

Canadiens defeat Canucks 6-3 with 3-goal outburst in third period

AISpeech's Smart Mobility Solutions Debut at CES 2026

Chinese yuan strengthens to 7.0103 against USD Tuesday

Maxey scores 33 as 76ers use 80-point first half to beat Raptors 115-102

Copp scores in OT, lifts Red Wings to 4-3 win over Hurricanes after retiring Sergei Fedorov's jersey

U.S. dollar ticks down

Catton scores tiebreaking goal in 3rd period as Kraken rally from 2 goals down and beat Rangers 4-2

Lightning beat Flyers for 10th straight win as Cooper notches 600th win

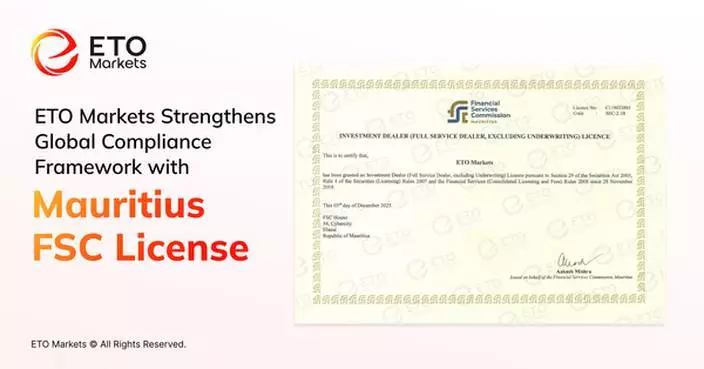

ETO Markets Strengthens Global Compliance Framework with Mauritius FSC License

Pascal Siakam and Pacers nip Celtics 98-96 for 1st 3-game win streak of season